Picture this: you’re in the middle of a bustling warehouse, and you need to mark a massive piece of equipment. Enter the handheld laser marking system.

Handheld laser marking systems are game-changers in industry settings, offering unmatched flexibility and precision. They’re perfect for marking large or immovable objects on-site, which boosts efficiency and minimizes downtime. Plus, they produce high-quality marks on various materials while keeping maintenance costs low.

I remember the first time I handled a handheld laser marking system. I was nervous, but the ease of use quickly won me over. These tools feel like extensions of your hands, allowing you to maneuver and mark with accuracy that stationary machines sometimes struggle to achieve. With every precise laser etch, I could see how these systems could transform the way we work, offering solutions that save time and resources without compromising on quality. For anyone in the industry, understanding the capabilities of these handheld systems is key to unlocking their full potential.

Handheld laser marking systems reduce production downtime.True

They allow on-site marking, eliminating the need to move objects.

Handheld laser markers require frequent maintenance.False

These systems are designed to have minimal maintenance needs.

How Do Handheld Laser Marking Systems Work?

Ever wondered how a simple handheld device can leave a lasting mark on materials? Let’s dive into the fascinating world of handheld laser marking systems and see how they make it happen.

Handheld laser marking systems use concentrated light beams to etch patterns or text onto materials. These systems employ fiber lasers, known for durability and precision, ideal for metals and plastics.

The Basics of Laser Technology

You know those moments when you’re trying to etch your initials onto something, and it ends up looking more like a toddler’s scribble? Well, handheld laser marking systems save you from that mess. They use a focused laser beam1 to create permanent marks on surfaces with precision and ease. The beauty of the handheld variant is its portability—it’s like carrying a magic wand that turns ordinary surfaces into personalized masterpieces.

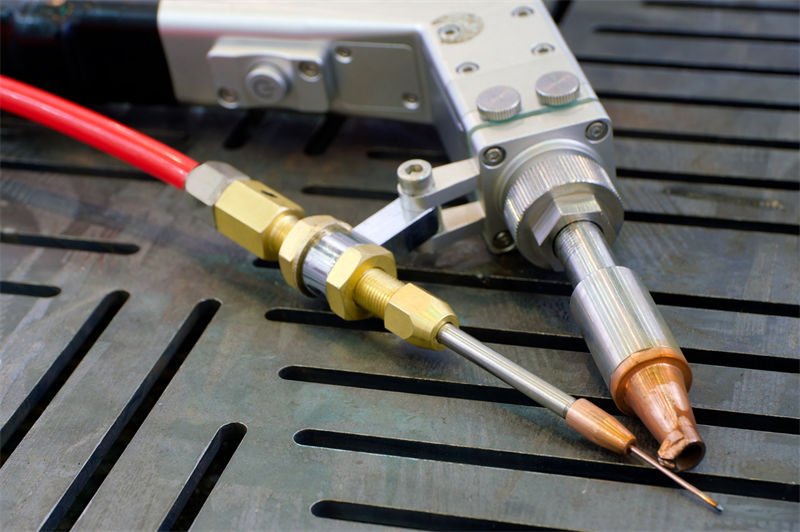

Components of a Handheld Laser Marker

Let’s break it down. Imagine your handheld laser marker as a mini orchestra:

| Component | Function |

|---|---|

| Laser Source | Generates the beautiful beam for marking |

| Control System | Ensures everything runs smoothly by adjusting power and operations |

| Scanner | Directs this laser light show precisely where you need it |

The laser source is like the lead violinist, generating the beautiful beam that does the marking. Then there’s the control system, the conductor, ensuring everything runs smoothly by adjusting power and operations. Lastly, the scanner—the nimble fingers that direct this laser light show precisely where you need it. It’s equipped with galvanometers to pinpoint the exact spot on your material.

Types of Lasers Used

Most handheld systems boast fiber lasers, which are like the Swiss army knives of the laser world—compact, efficient, and perfect for metals and plastics. They’re practically maintenance-free, which means less time fiddling and more time marking. Occasionally, you’ll see CO2 lasers2 making an appearance, especially when dealing with organic materials like wood or leather.

Operational Principles

So, how does it all work? When you activate the laser, it’s like sending a tiny army to interact with the surface material. This interaction can cause changes such as color variations, engraving, or even surface ablation depending on what you’re aiming for. You can tweak the marking speed3 to get just the right depth and clarity for your project.

Applications Across Industries

Here’s where these handy devices really shine. Whether you’re in automotive, aerospace, electronics, or jewelry industries:

- Marking serial numbers on metal parts for cars.

- Crafting delicate designs on jewelry pieces.

- Labeling medical devices with high precision meeting stringent legibility standards.

The possibilities are vast! If you’re curious about specific industry applications, you can learn more about industry applications4 and discover their full potential. It’s pretty amazing how something so compact can have such a big impact!

Handheld laser markers use fiber lasers for marking.True

Fiber lasers are compact and efficient, ideal for metals and plastics.

CO2 lasers are the primary type used in handheld markers.False

Fiber lasers are primarily used; CO2 lasers suit organic materials.

What Industries Benefit the Most from Handheld Laser Marking?

Picture this: a tool so versatile, it boosts efficiency across multiple industries. Curious? Let’s dive into how handheld laser marking is shaking things up!

Industries that reap significant benefits from handheld laser marking include automotive, aerospace, electronics, and pharmaceuticals. This innovative technology enhances production by offering unmatched precision, durability, and compliance with industry standards, ensuring efficient processes and improved product traceability.

Automotive Industry: Precision and Durability

Imagine working on a car engine and knowing that every part has been meticulously marked to ensure it withstands the test of time. That’s the magic of handheld laser marking in the automotive sector5. It’s like giving each component a unique identity card that endures even the harshest environments—essential for traceability and quality control. I often think about how these markings on engine parts or transmission gears are akin to a personal signature, ensuring authenticity and reliability.

| Component | Type of Marking |

|---|---|

| Engine Parts | Serial Numbers |

| Transmission Gears | QR Codes |

| Chassis | VIN Numbers |

Aerospace: Compliance and Traceability

In the world of aerospace, where safety and compliance are non-negotiable, handheld laser marking becomes a true hero. The aerospace industry6 counts on this technology to engrave unique identifiers on parts, meeting rigorous regulations. Picture knowing that every component can be tracked throughout its lifecycle—this is not just about following rules; it’s about ensuring passenger safety and trust.

Electronics: Miniaturization and Efficiency

If you’ve ever marveled at how tiny gadgets manage to have clear markings without any clutter, you’re witnessing the wonders of handheld laser marking in electronics. For manufacturers, especially in microchip manufacturing7, this technology is a game-changer. It allows for precise markings on small components, vital for efficiency and space management. I can relate to the satisfaction of fitting everything perfectly into a small space without losing essential information.

Pharmaceuticals: Safety and Compliance

Have you ever wondered how medicine packaging remains so precise and informative? The pharmaceutical industry8 relies heavily on handheld laser marking to ensure every package is safely marked and compliant with health regulations. It’s about protecting consumers from counterfeits and maintaining brand integrity. This technology provides that extra layer of safety—like a guardian ensuring that what’s inside is genuine and safe.

Handheld laser marking isn’t just a tool; it’s a silent partner enhancing capabilities across various industries by boosting precision, compliance, and efficiency. It’s fascinating how it plays a pivotal role in improving production while ensuring adherence to stringent industry standards.

| Industry | Key Benefit |

|---|---|

| Automotive | Durability & Traceability |

| Aerospace | Compliance & Safety |

| Electronics | Precision & Efficiency |

| Pharmaceuticals | Safety & Compliance |

Handheld laser marking enhances automotive part durability.True

Automotive parts marked with lasers withstand harsh environments, ensuring traceability.

Pharmaceuticals use laser marking for aesthetic purposes.False

Laser marking in pharmaceuticals is for safety and compliance, not aesthetics.

Are Handheld Laser Marking Systems Cost-Effective?

Remember the thrill of discovering a gadget that promises to revolutionize your work? That’s how I felt when I first encountered handheld laser marking systems.

Handheld laser marking systems prove cost-effective by minimizing maintenance costs and offering durability and adaptability across various materials. While the upfront cost might seem daunting, the long-term savings and extended lifespan often make them a worthy investment.

Initial Investment Costs

I remember the first time I considered investing in a handheld laser marking system. The sticker price gave me pause, ranging from $5,000 to $15,000 depending on the model’s capabilities. At first, I wondered if this was really the right move for my business. But after weighing the potential benefits, it became clear that the initial cost might just be a gateway to long-term gains.

Operational Savings

After making the leap, I quickly realized that these systems were not just about initial costs. Unlike traditional marking methods that require constant replenishment of consumables like inks or stencils, the laser systems were remarkably low-maintenance. A bit of software updating here and some lens cleaning there, and that was it. Over time, these minimal upkeep requirements translated into substantial savings.

Versatility Across Industries

One of the real eye-openers was seeing just how versatile these systems were. They could easily handle a variety of materials—metals, plastics, even wood. This flexibility opened up new opportunities across different industries, from automotive to electronics. I found myself tapping into markets I hadn’t considered before, thanks to a system that could mark both stainless steel and anodized aluminum with ease, offering increased flexibility9.

Longevity and Durability

The durability of these systems is another aspect that can’t be overstated. They’re built tough enough to withstand even the harshest industrial environments and can keep performing reliably for over a decade. This kind of longevity provides a long-term solution10 for any business’s marking needs, giving peace of mind that the investment will pay off well into the future.

| Factor | Cost Implication |

|---|---|

| Initial Investment | High |

| Maintenance | Low |

| Versatility | High |

| Longevity | High |

Taking all these factors into account, I’ve come to see handheld laser marking systems as more than just a tool—they’re a strategic investment in efficiency and capability. For anyone considering diving into this technology, it’s not just about what you spend today but how much you’ll save and gain in the long run with such efficient solutions11.

Handheld laser markers cost $5,000 to $15,000.True

The initial investment for these systems ranges from $5,000 to $15,000.

Laser marking systems need frequent maintenance.False

These systems require minimal maintenance compared to traditional methods.

How Do I Maintain My Handheld Laser Marker?

You know that feeling when your favorite gadget stops working just right? Handheld laser markers are no different. Keeping them in tip-top shape is crucial to avoid those frustrating breakdowns.

Keeping handheld laser markers running smoothly requires routine cleaning of lenses and mirrors, ensuring proper airflow, checking electrical connections, and updating software. A regular maintenance schedule boosts performance and cuts down on unexpected issues.

Regular Cleaning Tasks

I remember the first time I realized how dust can wreak havoc on my laser marker. It was like trying to see through fog. To keep your handheld laser marker in pristine condition, make it a habit to regularly clean the optical components, like lenses and mirrors. Trust me, a soft cloth or some compressed air works wonders in banishing dust and keeping that beam sharp. Proper cleaning techniques12 are your best friend here.

Ventilation and Cooling System

Overheating is like a silent enemy for your laser marker. I’ve learned the hard way that adequate ventilation is crucial. So, regularly check those cooling fans and air filters. Keeping them free from dust and blockages is key to preventing any overheating disasters.

Inspecting Electrical Connections

I once had a scare with a faulty connection that almost led to an unexpected shutdown. Since then, I’ve made it a point to inspect all electrical connections diligently. Loose or corroded connections can be sneaky troublemakers. Using a multimeter to test for voltage fluctuations13 can save you from potential headaches.

| Maintenance Task | Frequency | Tools Needed |

|---|---|---|

| Clean lenses & mirrors | Weekly | Soft cloth, air |

| Check ventilation system | Monthly | Air compressor |

| Inspect electrical parts | Bi-monthly | Multimeter |

Software Updates

Keeping up with software updates feels like keeping up with the latest trends, but it’s crucial for maintaining efficiency. Updates not only bring new features but also patch up bugs and enhance security. Make sure you’re always running the latest manufacturer’s updates14.

Scheduled Maintenance Plan

Having a scheduled maintenance plan has been a game-changer for me. It’s like having a cheat sheet that keeps everything running smoothly. This plan should include all the tasks I’ve mentioned above, tailored to the specifics of your model and how often you use it.

A well-thought-out maintenance schedule doesn’t just boost efficiency—it significantly reduces the risk of unexpected downtime, ensuring that your business operations run smoothly15. It’s all about keeping your equipment happy, so you stay happy too.

Regular cleaning of lenses enhances laser precision.True

Dust on optical components affects beam quality, reducing precision.

Software updates are optional for laser markers.False

Updates fix bugs, improve security, and introduce new features.

Conclusion

Handheld laser marking systems enhance efficiency and precision in various industries, offering low maintenance costs, versatility across materials, and significant long-term savings despite higher initial investments.

-

Focused laser beams are essential for precise marking. Discover how they operate to enhance your understanding of laser technology. ↩

-

Understanding the differences helps choose the right laser type for specific materials and applications. ↩

-

Adjusting marking speed impacts depth and clarity, crucial for achieving desired results. ↩

-

Explore how different industries benefit from these versatile tools to see their full potential. ↩

-

Explore how laser marking improves precision and durability in automotive manufacturing. ↩

-

Understand the importance of laser marking for traceability and safety in aerospace components. ↩

-

Discover how laser marking enhances precision and efficiency in electronics production. ↩

-

Learn about the role of laser marking in ensuring pharmaceutical safety and compliance. ↩

-

Explore how these systems work on various materials, enhancing their applicability across industries. ↩

-

Learn about the durability and lifespan of these devices, ensuring long-term cost benefits. ↩

-

Understand the key advantages that make these systems an effective solution for businesses. ↩

-

Explore effective cleaning techniques to enhance laser performance. ↩

-

Learn how to diagnose electrical issues early with a multimeter. ↩

-

Stay informed about new features and bug fixes. ↩

-

Discover how a maintenance plan minimizes downtime. ↩