Have you ever marveled at a beautifully engraved piece of wood or glass? I certainly have! CO2 laser engravers are the magical tools behind those stunning creations, perfect for anyone from hobbyists to professionals.

CO2 laser engravers offer high precision, versatility in material application, efficiency in production, and enhanced creative potential. They excel in engraving non-metal materials such as wood, acrylic, and glass, making them ideal for crafting and manufacturing projects.

But there’s so much more to discover! Understanding how these machines operate and their specific advantages can truly elevate your decision-making process. Let’s dive deeper into the fascinating world of CO2 laser engravers!

CO2 laser engravers are ideal for engraving metals.False

CO2 lasers are primarily used for non-metal materials like wood and acrylic.

How Does a CO2 Laser Engraver Work?

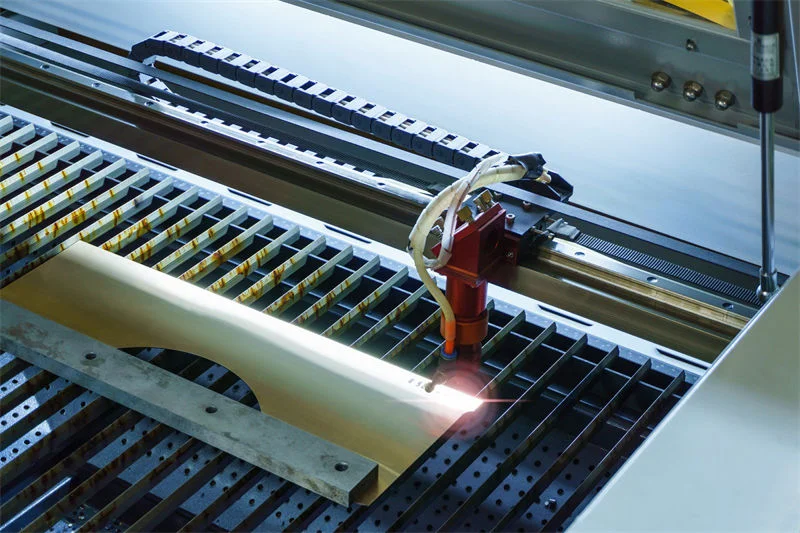

The CO2 laser engraver is a fascinating technology that transforms ideas into tangible creations using concentrated laser beams.

A CO2 laser engraver works by emitting a high-energy laser beam that interacts with materials to vaporize, melt, or induce chemical changes, creating precise engravings. It utilizes a CO2 gas mixture as the laser medium, making it ideal for non-metal materials like wood, acrylic, and glass.

Understanding the Basics of CO2 Laser Engraving

CO2 laser engravers operate by producing a beam from a CO2 gas mixture, which is then amplified to generate a powerful and focused laser. This laser is capable of cutting through or engraving various materials with remarkable precision. The process begins with the design input where operators use specialized software to set the parameters such as power and speed, ensuring the desired outcome.

Key Components of a CO2 Laser Engraver

- Laser Tube: The heart of the CO2 laser engraver, the laser tube contains the CO2 gas mixture. When excited by electricity, it emits the laser beam used for engraving.

- Optical System: This includes mirrors and lenses that guide and focus the laser beam onto the material. Proper alignment and focusing are critical for achieving precise results.

- Control Software: Allows users to input designs and control the laser’s path, power, and speed. Advanced software1 can handle complex tasks and ensure optimal performance.

- Cooling System: Typically uses water to prevent overheating of the laser tube during operation, maintaining consistent performance.

The Engraving Process

- Design Input: Operators create or upload designs using computer software. This step involves setting the engraving parameters specific to the material type.

- Laser Emission: The control system initiates the laser emission. The optical system focuses the beam onto the material surface.

- Material Interaction: As the laser beam interacts with the material, it causes physical changes like vaporization or melting, forming precise and permanent marks.

Factors Influencing Engraving Quality

- Power Settings: Adjusting power levels can alter engraving depth and clarity. Lower power might lead to incomplete marks, while higher power could damage the material.

- Speed Control: Speed affects how long the laser interacts with the material. A balance between speed and power is essential for optimal results.

- Focus Adjustment: Accurate focusing ensures that the laser beam’s energy is concentrated precisely where needed, crucial for detail-oriented work.

- Material Properties: Different materials react differently to laser energy. Understanding material properties2 can help in adjusting settings for best results.

CO2 laser engravers excel in producing intricate designs on non-metal materials due to their precise control and versatility. Their capability to handle various materials makes them indispensable tools in both hobbyist and industrial settings.

CO2 laser engravers can engrave metal surfaces.False

CO2 lasers are ideal for non-metal materials like wood and acrylic.

The laser tube contains a CO2 gas mixture.True

The CO2 gas mixture in the tube is essential for laser emission.

What Materials Can You Engrave with a CO2 Laser?

CO2 lasers are popular for their versatility in engraving a wide range of non-metallic materials, making them ideal for various applications.

CO2 lasers can engrave materials like wood, acrylic, glass, leather, fabric, rubber, and certain plastics. Their adaptability in handling diverse materials with precision makes them an excellent choice for both industrial and artistic purposes.

Understanding Material Compatibility with CO2 Lasers

CO2 lasers are engineered specifically for non-metal materials, offering a spectrum of possibilities in terms of engraving. Each material interacts differently with the laser beam, which influences the engraving technique and outcome. Here’s a closer look at some common materials you can engrave with a CO2 laser:

Wood

Wood is perhaps the most popular material for CO2 laser engraving due to its organic nature, which responds well to the laser’s heat. The laser can burn and vaporize the wood surface, resulting in detailed and sharp engravings. Woods like pine, birch, cherry, and walnut are particularly favored for their texture and grain patterns.

Acrylic

Acrylic is another favorite for its versatility and clarity. When engraved, it produces a frosted effect which contrasts beautifully against its clear surface. The laser can cut through acrylic smoothly, making it perfect for signs, awards, and decorative items.

Glass

Engraving on glass requires precision, as the laser can cause micro-fractures if not properly controlled. However, CO2 lasers excel at producing fine details on glass surfaces, suitable for custom glassware and decorative pieces. The key is to use lower power settings to avoid cracking.

Leather

Leather absorbs laser energy well, allowing for deep and detailed engravings. It’s crucial to adjust the laser settings appropriately to avoid burning or scorching the leather surface. Engraving on leather is common in fashion and accessory manufacturing.

Fabric

CO2 lasers can engrave delicate patterns on fabrics without fraying the edges. This ability is particularly useful in fashion design and textile industries where precision is paramount.

Rubber

Rubber engraving with a CO2 laser is typically used to produce stamps. The laser can accurately remove the rubber material to create raised designs that transfer ink effectively.

Plastics

While CO2 lasers work on a variety of plastics, caution is necessary as some may emit harmful fumes. It’s advisable to check the compatibility of the specific plastic type being used.

Factors to Consider When Engraving Different Materials

- Power Settings: Adjusting the power is essential to ensure clean engravings without damaging the material.

- Speed: The speed of the laser affects how much energy is absorbed by the material; slower speeds usually result in deeper engravings.

- Resolution: Higher resolution settings provide more detailed engravings but may require more time to complete.

- Ventilation: Always ensure proper ventilation when engraving materials that may emit harmful fumes.

By understanding these factors and leveraging the capabilities of CO2 lasers3, you can achieve remarkable results across diverse materials. Each material offers unique challenges and opportunities, making it crucial to tailor your approach accordingly.

CO2 lasers can engrave metals effectively.False

CO2 lasers are primarily designed for non-metallic materials.

Acrylic engraving with CO2 lasers creates a frosted effect.True

The laser produces a frosted contrast on clear acrylic surfaces.

Why Choose a CO2 Laser Engraver Over Other Types?

In the realm of laser engraving, selecting the right machine is crucial for achieving optimal results across various materials and applications.

A CO2 laser engraver is ideal for non-metal materials due to its precision, affordability, and versatility. It efficiently processes wood, acrylic, glass, leather, and textiles, making it suitable for both hobbyists and professionals. Compared to other laser types, CO2 lasers offer a broader application range and cost-effectiveness.

Precision and Versatility

CO2 laser engravers stand out for their ability to deliver high precision4 on a variety of non-metal materials. They achieve fine details and intricate designs, making them perfect for intricate work on wood, acrylic, and even delicate materials like paper. The versatility of CO2 lasers extends to their ability to cut and engrave a wide range of materials with ease.

Comparison of Material Compatibility:

| Material | CO2 Laser | Fiber Laser | UV Laser |

|---|---|---|---|

| Wood | ✓ | ✕ | ✕ |

| Acrylic | ✓ | ✕ | ✕ |

| Glass | ✓ | ✕ | ✓ |

| Leather | ✓ | ✕ | ✕ |

| Metals | ✕ | ✓ | ✕ |

Cost-Effectiveness

When considering budget constraints, CO2 laser engravers5 often emerge as the more affordable option compared to other laser types. Their operational costs are generally lower, and they require less maintenance over time. This cost advantage makes them particularly appealing to small businesses and hobbyists looking to maximize their return on investment without compromising quality.

User-Friendly Operation

One of the significant benefits of CO2 laser engravers is their ease of use. Many models come with intuitive software and user interfaces that make them accessible even to beginners. This user-friendly nature ensures a smoother learning curve compared to more complex systems like fiber lasers, which may require specialized knowledge.

Creative Potential

CO2 lasers open up vast creative possibilities due to their ability to process diverse materials. From customized gifts6 to intricate art pieces, the flexibility in design and material use allows users to explore a myriad of creative avenues. Additionally, the speed and precision of CO2 lasers mean that intricate designs can be achieved efficiently, offering a competitive edge in creative industries.

CO2 lasers are ideal for engraving metals.False

CO2 lasers are not suitable for metals; fiber lasers are preferred.

CO2 laser engravers offer cost-effective operation.True

They have lower operational costs and require less maintenance.

How Can a CO2 Laser Engraver Boost Your Business or Hobby?

From personalized gifts to intricate designs, CO2 laser engravers can transform your creative ideas into tangible products, elevating both your business and hobby pursuits.

CO2 laser engravers enhance businesses and hobbies by offering unmatched precision, diverse material compatibility, and efficiency. They enable intricate designs, customization, and rapid production, making them indispensable for small business branding and personal craft projects.

Precision and Detail in Crafting

CO2 laser engravers are renowned for their ability to produce intricate and detailed designs. Whether you’re engraving logos on wood or creating complex patterns on acrylic, these machines ensure high precision that hand tools simply cannot match. This precision is crucial for small business owners looking to brand their products with unique designs or for hobbyists aiming to achieve professional-grade results.

For instance, consider a small business specializing in personalized gifts. Using a CO2 laser engraver, they can offer customized items such as engraved wooden photo frames or acrylic keychains with meticulous detail. This level of customization not only enhances product value but also attracts a broader customer base.

Versatility Across Materials

One of the standout features of a CO2 laser engraver is its versatility. It can work on a variety of non-metal materials including wood, glass, leather, and even fabrics. This adaptability opens up a plethora of possibilities for both businesses and hobbyists.

For example, an artist can use the engraver to etch designs onto leather jackets or create intricate lace patterns on fabrics. This versatility allows for experimentation with different materials, leading to innovative products and art pieces.

Benefits of CO2 Laser Engravers7

Efficiency and Productivity Boost

Time is a critical factor in both business and hobbies. CO2 laser engravers offer significant time savings due to their speed and efficiency. They can quickly switch between tasks and materials without the need for extensive setup changes, which is particularly beneficial for small businesses managing multiple orders.

Imagine running a custom signage business; the ability to rapidly produce signs with varying designs and materials can significantly boost productivity. Similarly, hobbyists can complete more projects in less time, allowing for more creativity and exploration.

Expanding Creative Boundaries

For creative minds, CO2 laser engravers are tools that expand the boundaries of what is possible. They allow users to experiment with new techniques and materials that were previously difficult or impossible to work with using traditional methods.

Artists can explore mixed media projects by combining engraved wood with painted elements or fabric. Such experiments not only enhance artistic expression but also create unique pieces that stand out in markets flooded with mass-produced items.

In conclusion, whether you are a small business owner looking to enhance product offerings or a hobbyist wanting to explore new creative avenues, a CO2 laser engraver provides the precision, versatility, and efficiency needed to elevate your work to the next level.

CO2 laser engravers can engrave on metal materials.False

CO2 laser engravers are primarily for non-metal materials like wood and acrylic.

CO2 laser engravers improve business productivity.True

They enhance productivity with rapid production and efficient material switching.

Conclusion

In summary, CO2 laser engravers are invaluable tools that combine precision and versatility, empowering both creativity and productivity. Explore their benefits and consider how they could enhance your next project.

-

Discover software options that enhance CO2 laser engraver capabilities.: We offer the latest and most advanced software solutions for Co2 laser engraving machines. You can get Lightburn software directly to help both enthusiasts and … ↩

-

Learn how different materials respond to CO2 laser engraving.: Materials that absorb laser light effectively allow for better energy transfer and more precise engraving. CO2 lasers operate at a wavelength of … ↩

-

Discover how CO2 lasers handle various non-metal materials effectively.: A CO2 laser is activated by stimulating a mixture of gases with direct current (DC) voltage or with radio frequency (RF) waves. Discover all the features. ↩

-

Explore detailed capabilities of CO2 lasers in achieving high precision.: Discover our high-powered CO2 laser engraving machines. Ideal for businesses needing precision, powerful laser capabilities, and heavy-duty cutting. ↩

-

Understand cost differences between CO2 and fiber lasers.: Cost Differences. In terms of up-front cost, fiber lasers are more expensive per watt of power than CO2 devices. However, they typically have … ↩

-

Discover creative projects made possible with CO2 laser engravers.: Co2 Laser Project Ideas ; Lézervágott Fa · Green Journal · Wood Notebooks ; Puzzle Lights · Woodworking Tools Workshop · Paper Pop ; Come In Sign · Laser Signs. ↩

-

Discover more about the advantages of using CO2 laser engravers.: One of the standout benefits of CO2 lasers is their impressive versatility in handling a diverse range of materials. From acrylic and wood to … ↩