Why is the GWEIKE Laser Cutter So Expensive?

The GWEIKE laser cutter stands out due to its modern technology, sturdy construction, and exceptional accuracy. Its higher price reflects the advanced features that enhance productivity in professional settings. With automatic focusing and AI integration for predictive maintenance, these machines ensure minimal downtime and precise cuts across various materials. User-friendly interfaces simplify operation for all skill levels, while versatility makes them suitable for both creative projects and industrial applications. Compared to competitors like Glowforge and xTool, GWEIKE offers excellent value without compromising on quality or performance. This blog post explores the reasons behind the pricing of GWEIKE laser cutters and compares them with other brands to help potential buyers make informed decisions.

Why is the Senfeng Laser Cutter So Expensive?

Senfeng laser cutters command a higher price due to their cutting-edge technology, premium materials, and strong brand reputation. These machines offer unmatched precision and reliability in various industries. Their advanced features include fiber laser technology, CNC systems integration, auto-focus capabilities, and user-friendly software interfaces. Additionally, Senfeng’s commitment to safety with enclosed workspaces further enhances their value. While the initial investment may be significant, the long-term benefits of durability and low maintenance costs make them a wise choice for professionals seeking quality equipment. Understanding these factors can help potential buyers assess whether Senfeng laser cutters align with their operational needs and budget constraints.

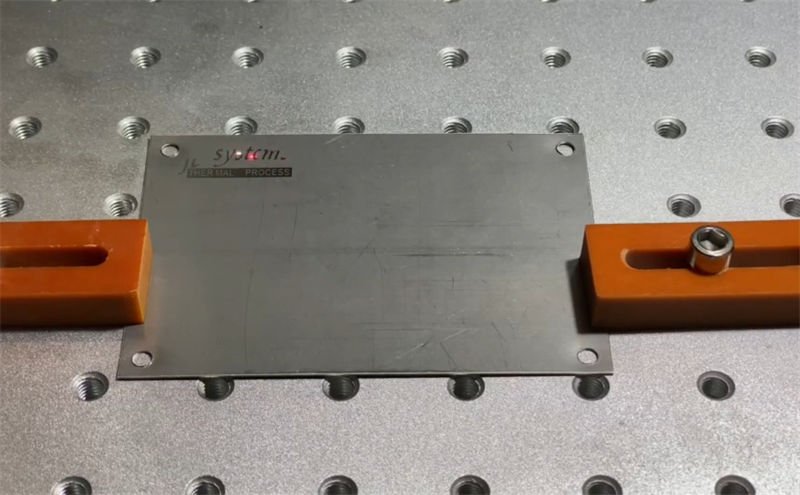

How Can You Adjust the Depth on a Milling Machine?

Adjusting the cutting depth on a milling machine is crucial for achieving precision in machining. This post explores various methods including manual adjustments with dials, test cuts, CNC programming techniques, and advanced technologies like adaptive control and laser measurement systems. Manual methods offer hands-on flexibility while CNC programming allows for precise control through coded instructions. Adaptive control systems enhance efficiency by making real-time adjustments based on sensor data. Laser measurement systems provide micron-level accuracy essential for high-precision applications such as aerospace manufacturing. Understanding these techniques can significantly improve machining quality and tool longevity.

Why Is CNC Machining So Popular in Today’s Market?

CNC machining has become a cornerstone of modern manufacturing due to its remarkable precision, efficiency, and flexibility. By utilizing computer-controlled operations, CNC machines achieve dimensional accuracy within ±0.01mm, ensuring consistent quality across various industries such as aerospace and medical devices. The automation inherent in CNC technology allows for continuous operation with minimal human oversight, significantly boosting productivity while reducing labor costs. Additionally, CNC machining excels at producing intricate designs that would be challenging with traditional methods. Its ability to quickly adapt to design changes through programmable adjustments makes it ideal for industries requiring rapid prototyping and iterative development. Overall, CNC machining reshapes the manufacturing landscape by delivering superior results efficiently and reliably.

Why Is the HGTECH Laser Cutter So Expensive and What Makes It Stand Out?

The HGTECH laser cutter’s high price reflects its advanced technology, quality components, and excellent after-sales support. These machines offer precision cutting across multiple materials, enhancing productivity in industries like automotive and aerospace. Their automation capabilities reduce human error while ensuring consistent performance. The non-contact processing method protects delicate materials from damage, making them ideal for sensitive applications. With a strong focus on research and development, HGTECH ensures long-lasting durability and reliability in their products. Investing in an HGTECH laser cutter means gaining a trustworthy partner that supports your business needs effectively.

Why Are Lead Laser Cutters So Expensive?

Lead laser cutters are known for their high prices, which stem from advanced technology, quality materials, and substantial operational costs. Understanding these factors helps buyers make informed decisions about investments in laser cutting equipment. The integration of automation and AI enhances precision and efficiency while the quality of raw materials directly influences production expenses. Additionally, operational costs such as maintenance and energy consumption play a crucial role in the overall expense of owning a lead laser cutter. For those seeking budget-friendly alternatives, diode and CO2 laser cutters offer effective solutions for smaller tasks without compromising on performance.

Why Are HSG Laser Cutters So Expensive?

HSG laser cutters command high prices due to their cutting-edge technology and superior performance. These machines incorporate advanced features like digital chuck technology and smart motion control systems, ensuring precision and efficiency. The significant investment in research and development allows HSG to innovate continuously, enhancing product quality over time. Additionally, the company’s global service network offers extensive support, reducing downtime and increasing customer satisfaction. While the initial costs may be daunting, the long-term benefits of reliability and productivity make HSG laser cutters a worthwhile investment for businesses looking to advance their operations.

Why Is the Bodor Laser Cutter So Expensive?

The Bodor Laser Cutter is renowned for its high cost due to advanced technology and quality components. It offers exceptional precision and efficiency in various applications, making it ideal for industries like automotive and aerospace. The machine’s versatility allows it to handle different materials effectively while maintaining accuracy. Additionally, Bodor provides excellent after-sales support, enhancing customer satisfaction and loyalty. This combination of features justifies the investment for businesses seeking reliable laser cutting solutions that improve productivity over time.

Why Are Chutian Laser Cutters So Expensive?

Chutian laser cutters command high prices because they incorporate cutting-edge technology and premium materials. Their robust customer support ensures longevity and reliability, appealing to professionals who prioritize quality over cost. Features like fiber lasers, automated focusing systems, and real-time monitoring enhance precision and efficiency. While cheaper alternatives exist, Chutian’s after-sales service fosters loyalty among customers by reducing downtime and operational issues. Understanding material choices also plays a crucial role in overall costs. This blog explores why investing in Chutian laser cutters can be worthwhile for businesses seeking top-tier performance.

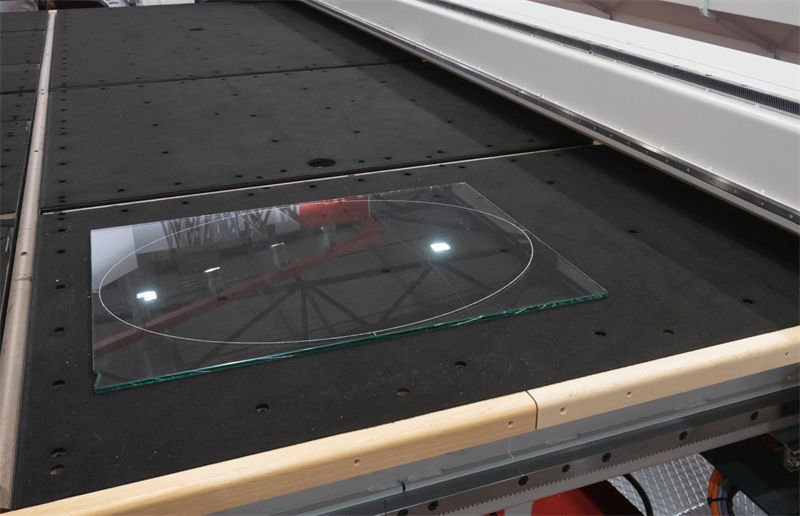

How Can You Effectively Cut Glass and Mirrors Using a Laser?

Laser cutting has transformed the glass and mirrors industry, providing exceptional precision and efficiency. In this post, I explore the advantages of laser technology over traditional methods, essential equipment needed, and the challenges you may face. Whether you’re an artist or manufacturer, understanding these insights will elevate your craftsmanship.

Can Laser Cleaning Damage Metal Surfaces?

Laser cleaning has transformed how we tackle contaminants like rust and paint on metal surfaces. While it appears effective and innovative, concerns linger about potential damage to the metals themselves. In this article, we explore the safety of laser cleaning, how it works, and what precautions should be taken to ensure a smooth process. Discover the advantages of this eco-friendly technology and understand why proper application is key to preserving metal integrity.

How Does a Laser Marking Machine Work?

Laser marking technology is transforming industries by providing precise and efficient solutions for labeling and tracking products. This article explores the different types of laser marking machines, how they operate, and what factors to consider when choosing the right one for your needs.