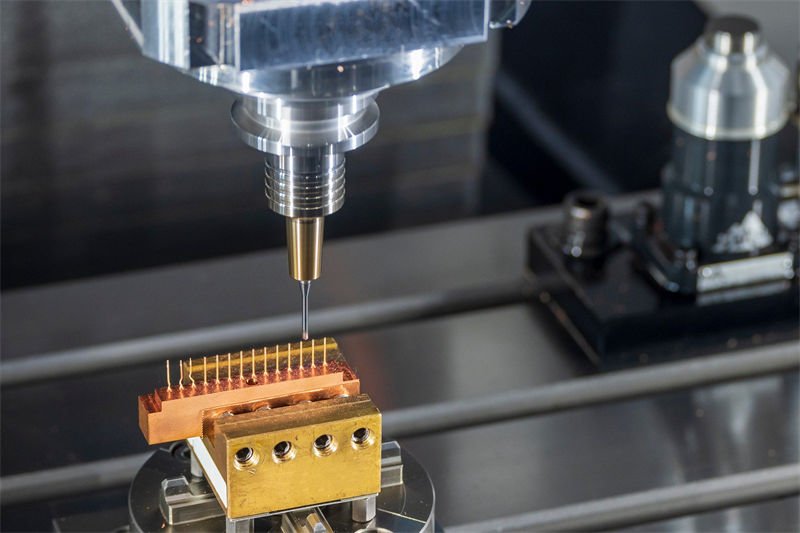

Tinkering with a milling machine to perfect the cutting depth is like fine-tuning a musical instrument—precision is key.

Adjusting the cutting depth on a milling machine can be done manually using dials or through programming on CNC machines. For manual machines, turn the dial to reach the desired depth. CNC machines offer programmed settings or adaptive control systems for real-time precision adjustments.

I remember the first time I stood in front of a milling machine, nervous yet excited. My mentor handed me the dial and said, "Give it a twist." It felt like steering a ship through uncharted waters. For those manual machines, it’s all about feeling the resistance as you turn that dial to the exact depth you need.

Now, when it comes to CNC machines, it’s a bit like playing a high-tech video game. You set your parameters and let the program do its magic. But just like any good gamer knows, sometimes you need to make those real-time adjustments using adaptive controls to keep everything running smoothly. It’s fascinating how these machines seem to anticipate your next move, almost like they have a mind of their own!

Manual adjustment is more precise than CNC programming.False

CNC programming allows for more precise control of cutting depth adjustments.

Adaptive control adjusts cutting depth based on cutting force.True

Adaptive control systems use sensor data to adjust depth, enhancing stability.

How do I manually adjust cutting depth for milling tasks?

Remember the first time you tinkered with a tool, eager to get everything just right? Adjusting cutting depth manually is like that—it’s all about precision and control.

Manual methods to adjust cutting depth include using machine dials for fine-tuning and test cuts for precision. Both offer adaptable solutions tailored to your project needs.

Using the Dial Method

Ever since I started milling, using the dial on my machine has been my go-to method for adjusting cutting depth. It’s like having a trusty sidekick that ensures precision. The dial, usually found on the knee or worktable, allows me to make those critical vertical adjustments. I remember once working on a complex piece, needing every millimeter to be perfect. By loosening the locking handle and turning the dial, I could achieve just the right depth—0.05mm per division in my case. It’s particularly handy for rough machining, where larger depths are required, and it’s a method I’ve come to rely on.

Test Cutting Approach

Then there’s the test cutting method, which feels like a meticulous dance between man and machine. It’s particularly useful when precise dials aren’t available or when I’m after that perfect fine-tune. I start by estimating an initial cutting depth based on my material and tools, perform a test cut, and then measure. I recall one time cutting into some stubborn aluminum—after a few rounds of adjustments and test cuts, I finally achieved the desired depth. Sure, it can be time-consuming, but for single pieces or small batches where precision is prioritized1 over speed, it’s invaluable.

Advantages and Considerations

These manual methods provide a hands-on flexibility that automated systems often lack. But they do require a good understanding of your machine’s mechanics2 and can be labor-intensive. These techniques are best when high precision isn’t as crucial because they offer hands-on control and immediate feedback through tactile engagement with the machine.

That being said, combining them with modern techniques like adaptive control systems or laser measurement can enhance both efficiency and accuracy.

Regardless of which method you choose, always prioritize safety and regular maintenance to keep things running smoothly. Nothing beats the satisfaction of a perfectly milled piece achieved through your own skills and techniques.

Turning the dial clockwise increases cutting depth.True

For most milling machines, turning the dial clockwise increases depth.

Laser measurement systems provide millimeter-level precision.False

Laser systems offer micron-level precision, not millimeter-level.

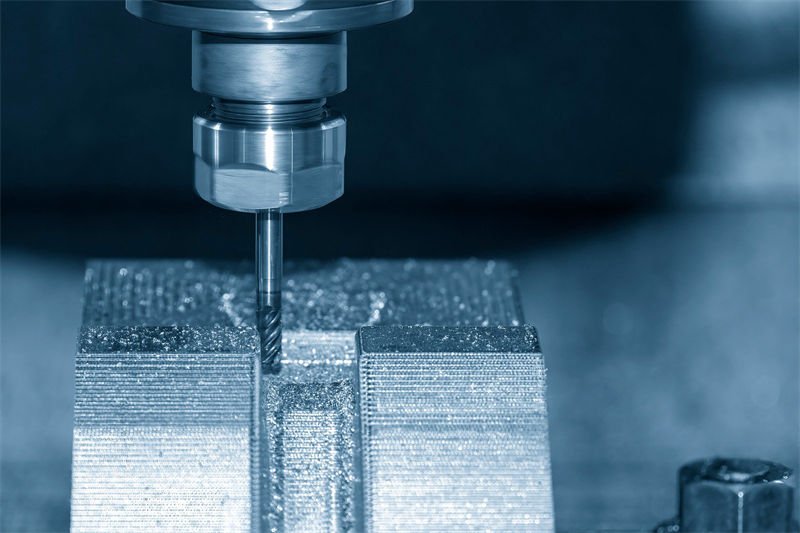

How does CNC programming influence cutting depth adjustments?

Picture this: you’re at the helm of a CNC machine, deciding how deeply the tool should cut into your material. It’s not just about precision—it’s about mastering the art of programming.

CNC programming meticulously controls cutting depth adjustments by directing the tool’s movement and depth through coded instructions, ensuring precise and repeatable machining tailored to material and tool specifics.

Understanding CNC Programming Basics

CNC programming involves writing a sequence of instructions that dictate machine tool movements. These instructions are often in G-code language3, allowing the operator to specify the depth of cut among other parameters.

When I first started learning CNC programming, it felt like deciphering a new language—G-code, to be exact. This language lets me write a series of commands that control every movement of the machine tool. Imagine being able to tell the machine exactly where to go and how deep to cut! For example, using a command like "G01 Z-1.0" means I can direct the tool to reach a specific depth along the Z-axis, which is incredibly empowering.

Programming for Depth Control

Cutting depth is crucial in CNC operations because it impacts both the machining time and the quality of the finished product. By setting parameters like "axial cutting depth," programmers can adjust how deep each pass cuts into the material. This adjustment can be critical when dealing with various materials4 that require different handling based on hardness or brittleness.

I’ve learned that by setting parameters like "axial cutting depth," I can fine-tune how deep each pass cuts into the material. This is especially important when I’m working with different materials—some are hard as nails, while others are as fragile as glass. Layered cutting has been a game-changer for me; it allows me to achieve the desired depth over multiple passes, reducing tool wear and protecting my workpiece from damage.

Advanced Techniques: Adaptive Control and Real-Time Adjustments

Modern CNC machines may incorporate adaptive control systems that automatically adjust cutting depth in real-time. These systems rely on feedback from sensors monitoring variables like cutting force or temperature. When anomalies are detected, the system can fine-tune the depth settings to maintain optimal performance and prevent tool damage5.

I’ve had the chance to work with modern CNC machines that use adaptive control systems. These systems are like having an extra set of eyes on the machine. They monitor things like cutting force and temperature, adjusting cutting depths on-the-fly to keep everything running smoothly. This feature has saved me from potential disasters more times than I can count!

Such systems use advanced algorithms to process data quickly, making on-the-fly adjustments that would be impossible with manual intervention alone. The result is a more stable machining process with improved efficiency and safety.

The Role of Laser Measurement Systems

Some CNC setups utilize laser measurement systems to enhance depth accuracy. These systems provide precise feedback about the distance between the tool and the workpiece, enabling micron-level adjustments for high-precision applications such as aerospace manufacturing.

One of the most exciting technologies I’ve encountered is laser measurement systems. These systems provide precise feedback about the distance between the tool and the workpiece, which is crucial for high-precision tasks like aerospace manufacturing. By constantly measuring and feeding back information about the Z-axis position, these systems allow programmers to refine their instructions, ensuring consistent results even when machining complex geometries or surfaces.

Implementing such technology has significantly enhanced manufacturing precision6.

Manual adjustment is used for CNC milling machines.False

Manual adjustments are typically for ordinary milling machines, not CNC ones.

Programming controls cutting depth in CNC milling.True

CNC machines use programming to set and control cutting depth accurately.

How Does Adaptive Control Technology Transform Depth Adjustment?

Ever wonder how technology can fine-tune precision like never before? Adaptive control technology is making that magic happen, especially when it comes to adjusting depth in machining.

Adaptive control technology uses real-time data to continuously monitor and adjust cutting parameters, such as depth, optimizing performance and extending tool life.

Understanding Adaptive Control Technology

Let me take you back to a time when I was fascinated by how machines seem to "think" on their own. I remember standing in a workshop, mesmerized by a milling machine that seemed almost alive, adjusting itself with a grace I couldn’t quite fathom. It turns out, the secret was adaptive control technology.

Adaptive control technology employs real-time monitoring to make autonomous adjustments during machining. It utilizes sensors to gather data on variables such as cutting force, temperature, and tool wear. This data informs the system’s algorithm to adaptively modify the depth of cut, ensuring consistent quality and reducing the risk of tool breakage or workpiece damage.

This technology is like having an astute assistant who never sleeps—constantly watching and tweaking. Imagine you’re cooking and your stove automatically adjusts the flame based on the soup’s temperature—that’s how adaptive control tech works! This real-time data feeds into a clever algorithm, which then adjusts the cut depth, ensuring everything runs smoothly and tools last longer.

A notable advantage of adaptive control is its ability to maintain optimal cutting conditions. For example, if increased cutting force indicates excessive depth, the system will automatically adjust to mitigate risks. This capability is crucial in machining applications7 where precision is paramount, such as in aerospace or automotive industries.

Applications in CNC Machines

Thinking back to my first encounter with CNC machines, I was struck by their precision. But even more impressive was how adaptive control systems elevated them to new heights. They integrate effortlessly with existing setups, providing dynamic tweaks during operations. Imagine if your car could adapt to changing road conditions without you lifting a finger!

In CNC milling machines, adaptive control systems integrate seamlessly with existing programming frameworks. They supplement traditional G-code programming by providing dynamic adjustments during operations. For instance, when encountering material inconsistencies, the system can alter the cutting depth without halting production.

For example, when a machine hits a patch of material that’s harder than expected, the system adapts without skipping a beat. This feature is invaluable for high-precision manufacturing8, where even minor deviations can lead to significant defects.

Benefits of Real-Time Monitoring

The heart of adaptive control lies in its real-time monitoring capabilities. Picture this: sensors acting like vigilant guards continually scanning for changes and making instant adjustments. This not only maintains quality but also safeguards against premature tool wear.

Real-time monitoring forms the backbone of adaptive control systems. By analyzing live data streams from various sensors, these systems preemptively adjust to maintain process stability. This proactive approach not only improves machining quality9 but also extends tool life by preventing unnecessary stress.

I’ve seen firsthand how this adaptability helps industries strike a balance between speed and precision, catering to both mass production and custom orders. By reacting swiftly to environmental shifts, these systems ensure depth adjustments align perfectly with material and machinery conditions—it’s like having an orchestra conductor keeping every note in harmony.

Moreover, the system’s ability to respond to environmental changes ensures that depth adjustments align with the current state of the material and machinery. This responsiveness is vital in sectors requiring rapid adaptation to evolving conditions or specifications.

Incorporating adaptive control technology means companies can thrive on both speed and accuracy—meeting demands for high-volume production while accommodating bespoke manufacturing needs.

Manual adjustment uses a dial for depth control.True

Manual adjustment involves turning a dial to control cutting depth.

Laser measurement systems adjust depth automatically.True

Laser systems provide precise, automatic depth adjustments in milling.

How Do Laser Measurement Systems Improve Milling Precision?

Imagine milling with the precision of a watchmaker, thanks to laser measurement systems transforming the game.

Laser measurement systems boost milling precision by employing laser sensors to track tool position and refine cutting depth with micron-level accuracy, ensuring flawless results.

Understanding Laser Measurement Systems

Picture this: a laser beam bouncing off your workpiece, like a dancer gliding across a stage, and returning data that lets you adjust your moves in real-time. That’s what laser measurement systems do in milling. They ensure that every cut is as precise as a master chef slicing vegetables, particularly critical in industries like aerospace, where even the tiniest error can have massive consequences.

Real-Time Data and Adjustments

I remember the first time I saw a laser system in action. It felt like magic. The laser keeps an eagle eye on the tool’s position, constantly feeding back information so precise that it feels like having a GPS for your milling machine. This real-time data means the system can make instantaneous corrections—much like how I might adjust my path when hiking to stay on course—ensuring each cut maintains the perfect depth.

Applications in High-Precision Industries

In industries like aerospace and automotive, precision isn’t just important—it’s everything. When you’re machining something as complex as an aero-engine blade, you can’t afford to be off by even a fraction of a millimeter. Laser systems make sure each cut is exactly as planned, reducing errors and safeguarding the integrity of these critical components.

Advantages Over Traditional Methods

Think about traditional milling adjustments—like trying to hit a bullseye with your eyes closed. They’re manual, prone to human error, and just not precise enough for today’s standards. Laser measurement systems, on the other hand, are like having a built-in autopilot that removes guesswork entirely by using precise, computer-guided adjustments.

Integration with CNC Systems

When you combine CNC milling machines with laser measurement systems, it’s like pairing peanut butter with jelly—each complements the other perfectly. With CNC programming alongside laser feedback, you can achieve adjustments so fine-tuned they’d impress even the most meticulous watchmaker. This marriage of technologies not only improves precision but also slashes setup time and material waste.

Challenges and Considerations

Of course, nothing’s perfect. Setting up these laser systems can be pricey, and they require a bit of specialized know-how to maintain. Plus, environmental factors like dust or temperature changes can throw them off their game. But with some understanding and planning, these challenges can be navigated effectively when implementing laser systems10.

Future Trends

Looking ahead, laser technology is only going to get better. Researchers are hard at work finding ways to make these systems more robust against environmental hiccups and enhance their integration with other tech like AI. It’s exciting to think about how these advancements could open up laser systems to more industries, offering competitive edges by boosting operational efficiency11 and product quality.

Manual dial adjustment is used for CNC milling machines.False

Manual dial adjustment is typically used for ordinary, not CNC, milling machines.

Laser measurement offers micron-level precision in milling.True

Laser systems provide high precision, crucial for aerospace and precision molds.

Conclusion

This guide explains how to adjust cutting depth on milling machines using manual methods, CNC programming, adaptive control technology, and laser measurement systems for precision machining.

-

Learn how precision machining improves cutting depth accuracy. ↩

-

Understand the mechanical workings of milling machines. ↩

-

Learn about G-code, the language of CNC programming. ↩

-

Understand how different materials impact cutting strategies. ↩

-

Explore strategies to avoid damaging your tools during CNC operations. ↩

-

Discover how laser systems enhance CNC precision. ↩

-

Explore how adaptive control enhances machining efficiency and precision. ↩

-

Discover how adaptive control ensures precision in manufacturing. ↩

-

Learn about the advantages of real-time monitoring for machining quality. ↩

-

Learn best practices for integrating laser systems into milling operations. ↩

-

Understand how operational efficiency can improve competitiveness. ↩