Ever thought why coherent fiber laser cutters cost so much? I have some insights to share.

Coherent fiber laser cutters cost a lot. They use advanced optics and detailed engineering. These machines have top-quality parts. They promise very precise and efficient cutting. They really do.

I remember when I first considered buying a coherent fiber laser cutter for my business. The cost was really high initially. But, after researching more, I realized that these machines are wonders of modern technology. Their advanced optics and precision engineering provide cuts that are both clean and extremely accurate. They really do. Buying one means getting quality and efficiency that may lift your work to a higher level. In the following sections, let’s explore these factors more to understand how they justify the investment.

Coherent fiber lasers use advanced optics.True

Advanced optics are crucial for the precision and efficiency of laser cutting.

High-quality components reduce laser cutter costs.False

High-quality components increase costs due to their durability and precision.

Why is Coherent Fiber Laser Technology Considered Cutting Edge?

Ever wondered why Coherent fiber lasers are so unique? Discover the magic in their advanced technology.

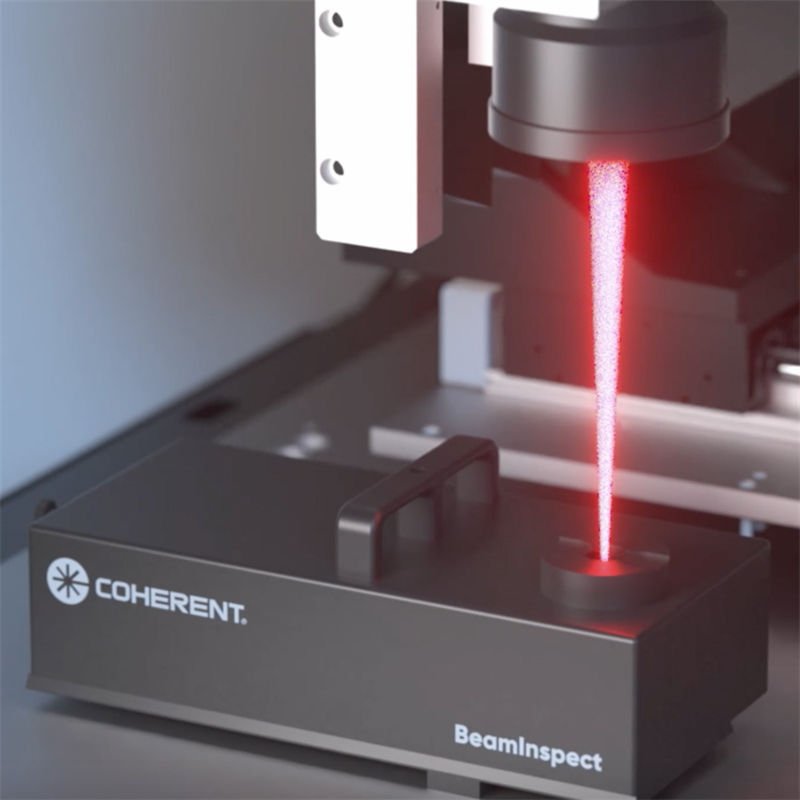

Coherent fiber laser technology is unique because of its incredible precision, reliability and energy efficiency. These lasers use the newest parts and production methods. Industries benefit greatly from this strength. Lasers perform excellently in many fields.

Precise and Dependable

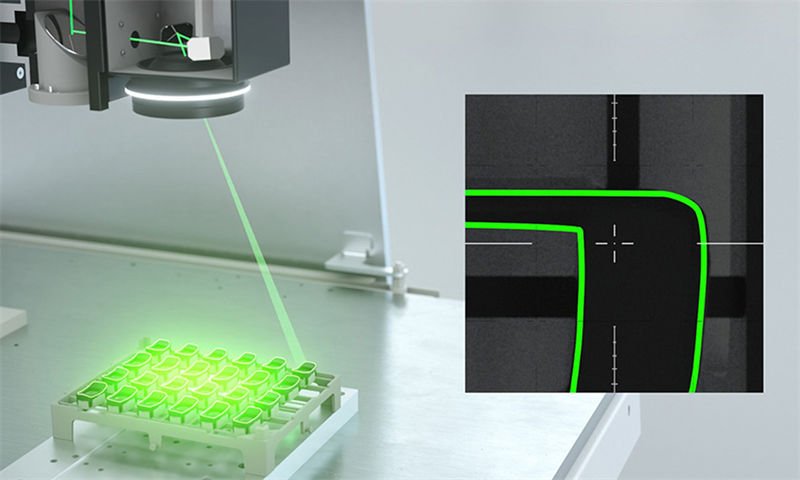

I recall my first encounter with Coherent fiber lasers during a critical project. Precision was vital. These lasers impressed me with their accuracy. They use top-notch parts and advanced lenses to create a sharp beam suitable for complicated jobs like micro-machining1. They seem crafted for people who prize reliability and precision.

Efficient Use of Energy

Energy efficiency truly transforms the game with Coherent fiber lasers. These lasers turn electrical power into light with almost no waste, reducing operating costs significantly. By aligning all parts perfectly through vertical integration2, they reduce losses to a minimum. If you focus on high efficiency, this represents a huge advantage.

| Feature | Benefit |

|---|---|

| Precision Optics | Enhanced cutting accuracy |

| Energy Efficiency | Lower operational costs |

| Reliable Performance | Consistent output quality |

Multiple Uses

The versatility of Coherent fiber lasers fascinates me. Whether in industrial production or medical fields, they adapt to various materials and processes effortlessly. Their modern design and sturdy build are like owning a reliable Swiss Army knife, thanks to their innovative design3.

Advanced Component Production

Coherent never cuts corners in component production. They focus on cutting-edge methods, overseeing every production step – from laser diodes to optical fibers – to guarantee top quality and dependability. This careful strategy allows for custom solutions4 tailored to diverse industry needs. Their commitment to quality and performance distinguishes them in the laser technology sector.

Coherent fiber lasers are more energy efficient than traditional lasers.True

They convert electrical energy into laser light with minimal waste.

Coherent fiber lasers are unsuitable for medical applications.False

They are versatile and can be used in various settings, including medical.

How Do Precision Engineering and Optics Affect Costs?

Do you ever think about how the details of precise engineering and optics raise the prices of everyday products? Learn how these areas change what you pay.

Precision engineering and optics influence costs. They dictate material accuracy, manufacturing methods and production volume. These fields improve product quality. High-quality products need specialized equipment. They need trained workers, too. These factors significantly raise expenses. Real investments become necessary.

The Role of Precision Engineering in Cost Management

Precision engineering has always intrigued me. It turns raw materials into well-crafted parts, much like a chef creates a gourmet meal from simple ingredients. This method reaches very high accuracy, reducing mistakes and waste, which saves money over time. However, just like buying an expensive, high-quality oven, it needs an initial investment in advanced machines like CNC systems and the skill to operate them. This choice might seem hard at first but often balances out with the efficiency and accuracy gained.

| Factor | Impact on Cost |

|---|---|

| Material Precision | Reduces waste but may increase initial costs due to higher quality materials. |

| Manufacturing Tech | Advanced machinery reduces errors but involves high capital expenditure. |

| Skilled Labor | Enhances quality but increases operational costs due to specialized training requirements. |

How Optics Influence Economic Considerations

Exploring optics opened a world where small changes have big impacts. Optical parts play key roles, from medical imaging to laser cutting, needing careful processes like coating and polishing. It’s like polishing a jewel; it improves the clarity but needs time and skill, affecting production costs5.

- Coating Techniques: Special coatings boost performance yet increase costs. New ways in this field try to balance quality and affordability.

- Polishing Methods: Good polishing makes things clearer and more effective, yet requires costly equipment and expert workers.

Synergy Between Precision Engineering and Optics

Precision engineering and optics together create something special, like perfect harmony in music. They drive quality and innovation forward. Consider laser systems – where the exact fit of optical parts is crucial. This careful setup might cost more at first but results in excellent performance.

- Quality Assurance: Strict testing and controls help keep standards high but might lengthen production time and raise costs.

- Innovation: Putting money in research for new materials or methods often leads to cost-saving solutions, improving market competitiveness.

Understanding these factors aids people in deciding where to put their money for the best cost savings and product quality, creating strategic advantages in a tough market.

Precision engineering reduces long-term costs.True

Investments in precision engineering reduce waste and increase efficiency, lowering long-term expenses.

Optical components are cheap to produce.False

Producing optical components requires costly processes like coating and polishing.

Is Investing in Operational Efficiencies Worth the Cost?

Do you ever think about spending money on that new gear? Is it really worth it?

Operational efficiencies prove the price worthwhile when savings in cost and increases in productivity surpass the initial spending. Evaluating less downtime, better quality and smoother processes helps discover the true worth of an upgrade. Real value appears.

Understanding Operational Efficiencies

I often stood in my small office in Istanbul, examining another spreadsheet filled with costs and benefits. Operational efficiency means doing tasks in a smart way, especially in my world of laser equipment. Picture upgrading to a machine that not only lowers maintenance costs but also increases production speed. That’s the key spot I look for to remain competitive.

Cost-Benefit Analysis

Every time a possible investment appears, I take out my trusty cost-benefit analysis6 sheet. You know the feeling when your old machine uses energy like there’s no tomorrow? I have experienced that. It’s about finding balance: do lower energy bills and fewer defects make up for the initial expense? Here is a simple table I often use:

| Cost Factor | Before Upgrade | After Upgrade |

|---|---|---|

| Energy Use | High | Low |

| Maintenance | Frequent | Infrequent |

| Output | Moderate | High |

Real-World Applications

Consider Alexander7, for instance. Running his e-commerce business alone from Russia, he chose to invest in software that automates order processing. I chatted with him once and he shared how those operational improvements cut errors and sped up transactions. It’s not just about saving time; it’s about bringing happiness that keeps customers coming back.

Measuring Success

From my experience, metrics are like a compass guiding me through business choices. Key Performance Indicators (KPIs) such as cycle time reduction and customer satisfaction scores provide clear proof of success. I once discussed with Terasa8 how she measures supplier lead times against delivery performance – it’s fascinating how these numbers tell the story of efficiency improvements.

The Role of Technology

Technology is much more than a buzzword; it’s a lifeline. Using advanced laser systems9 has brought precision and speed to my business. It’s like moving from a bicycle to a jet – everything becomes faster and more efficient. With cutting-edge software, I closely watch performance and make smart, data-driven choices.

Exploring these views allows anyone in this field to gain insights into how strategic investments in smart solutions not only balance their costs but exceed them, leading to greater success.

Machine upgrades always reduce maintenance costs.False

While upgrades often reduce costs, not all upgrades guarantee savings.

KPIs are essential for assessing operational efficiency.True

KPIs provide measurable data to evaluate improvements in efficiency.

Is Investing in a Coherent Fiber Laser Cutter Worth It?

Curious if a coherent fiber laser cutter truly transforms your business? Discover the possible advantages and decide if it deserves your valuable money.

Investing in a coherent fiber laser cutter improves precision. Waste decreases significantly. Productivity sees a notable rise. Initial costs are high. Upkeep requires regular attention and funds. Analyze business needs and budget for its true worth.

Coherent Fiber Laser Cutters: Why Are They Unique?

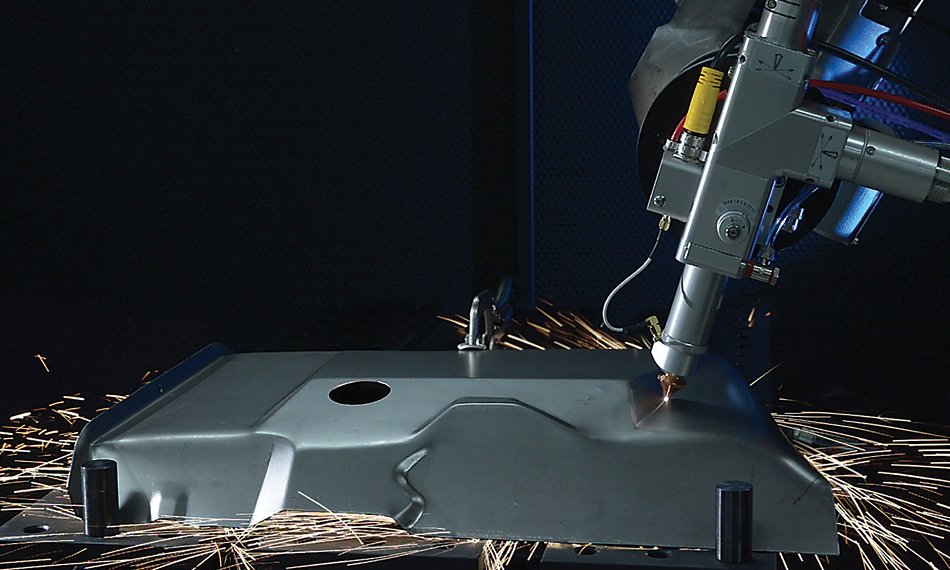

Picture this: I stand in my small workshop, watching our new coherent fiber laser cutter cut through metal smoothly. The precision amazes me. These machines, unlike old cutting methods, use a very focused laser beam. The result is cleaner edges and much less material waste.

This technology uses a laser source that is solid-state, using far less energy than the old CO2 lasers. This leads to lower running costs – important for anyone, like me, worried about high electricity bills. For businesses focused on being sustainable10, this is not just nice but necessary.

Cost Factors: Initial Spending vs. Future Benefits

I remember when I thought of buying our first coherent fiber laser cutter. The price was shocking – tens of thousands of dollars, perhaps more. But I thought of the possible benefits. More productivity and less waste might cover this big upfront cost.

If you handle complex designs or large production volumes, the precision and speed of these machines could really improve efficiency. I suggest talking to industry experts11 to really work out the numbers.

Maintenance and Help

Regular maintenance is like changing your car’s oil; it keeps everything working well. It means checking the laser source, cleaning parts and updating software. Working with a supplier that offers good technical support12 helps a lot, especially when problems pop up.

Having someone dependable for training and fixing issues has saved me many headaches – and some sleepless nights too.

Uses and Success Stories

These cutters change the game in fields where precision is crucial – like cars or planes. I once read a case study13 about a car company that improved production by 30% after switching.

For smaller businesses like mine, in metalwork or custom builds, offering precise, fast cuts can give a big competitive edge.

| Feature | Benefit |

|---|---|

| Precision | Cleaner cuts, reduced waste |

| Speed | Increased production efficiency |

| Energy Efficiency | Lower operational costs |

| Versatility | Suitable for various materials |

Checking Out the Market

Before jumping in, look at the marketplace. Many models and brands exist, each with different features like laser power, speed and bed size.

Connecting with online communities14 gives useful insights from other users with experience. Real-world feedback tells more than any brochure.

In Summary

Though coherent fiber laser cutters are expensive and need careful thought about costs and maintenance, their benefits could be larger than the challenges. Examine these factors compared to your business goals to see if this investment fits your needs.

Coherent fiber laser cutters are more energy-efficient than CO2 lasers.True

Coherent fiber lasers use solid-state sources, requiring less power.

Coherent fiber laser cutters are unsuitable for intricate designs.False

Their precision makes them ideal for intricate designs and cuts.

Conclusion

Coherent fiber laser cutters are expensive due to advanced optics, high-quality components, and precision engineering, offering significant efficiency and accuracy benefits for various industries.

-

Understand how fiber lasers excel in precision tasks like micro-machining. ↩

-

Learn how vertical integration enhances laser performance and efficiency. ↩

-

Explore the impact of design innovations on laser versatility and adaptability. ↩

-

Discover how Coherent offers tailored solutions for specific industry needs. ↩

-

Explore how optical coatings and polishing impact the cost, balancing quality with affordability. ↩

-

Learn how to effectively conduct a cost-benefit analysis to determine if equipment upgrades are financially viable. ↩

-

Discover the advantages of automating order processing, improving efficiency and customer satisfaction in online businesses. ↩

-

Explore key performance indicators that procurement managers use to measure supplier efficiency and enhance operational processes. ↩

-

Understand how advanced laser systems contribute to operational efficiency through precision and speed enhancements. ↩

-

Learn how fiber laser cutters contribute to sustainability through energy efficiency and reduced waste. ↩

-

Discover how businesses calculate the return on investment for fiber laser cutters based on improved efficiency. ↩

-

Find out why technical support is crucial for maintaining the performance of fiber laser machines. ↩

-

Read about real-world applications and results achieved by companies using fiber laser cutters. ↩

-

Check user reviews to gain insights into the performance and reliability of different fiber laser cutter models. ↩