Navigating the world of CNC machines can feel overwhelming. Choosing between a CNC lathe and a CNC milling machine isn’t just a technical decision; it’s about aligning with your project needs, efficiency, and ultimately, your success.

CNC lathes are ideal for machining rotational parts like shafts with high precision, while CNC milling machines excel at creating complex shapes and planes. The choice depends on the specific requirements of your project, including precision, efficiency, and industry application.

Let’s explore the distinct features of these machines and how they align with different manufacturing needs. Whether you’re in the automotive sector or mold-making industry, understanding these differences is crucial.

CNC lathes are better for rotational parts than CNC milling machines.True

CNC lathes excel in precision and efficiency for machining rotational parts.

What Are the Core Differences Between CNC Lathes and Milling Machines?

When it comes to precision machining, CNC lathes and milling machines offer distinct capabilities, each tailored to specific tasks and industries.

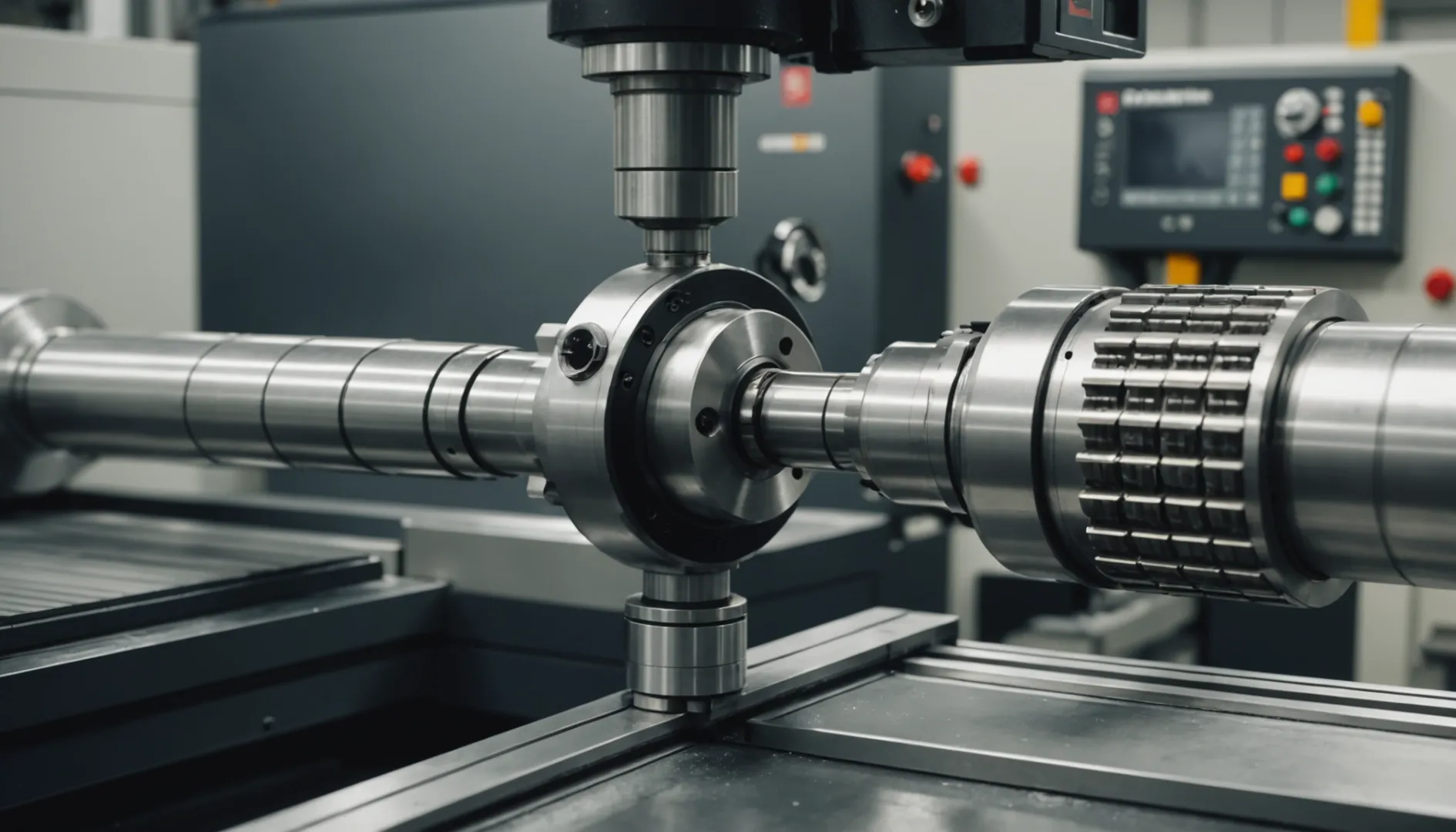

CNC lathes are designed for machining cylindrical parts with high accuracy, focusing on rotating the workpiece, while CNC milling machines handle complex shapes and contours, using a rotating tool. The choice hinges on your project’s geometry and precision demands.

Geometry of Machined Parts

The primary difference between CNC lathes and milling machines lies in the geometry of the parts they are best suited to machine.

-

CNC Lathes: These machines are optimized for machining rotational parts1, such as shafts and disks. The workpiece rotates against a stationary cutting tool, allowing for precise circular shapes and threads. This makes them ideal for automotive components like half-shafts.

-

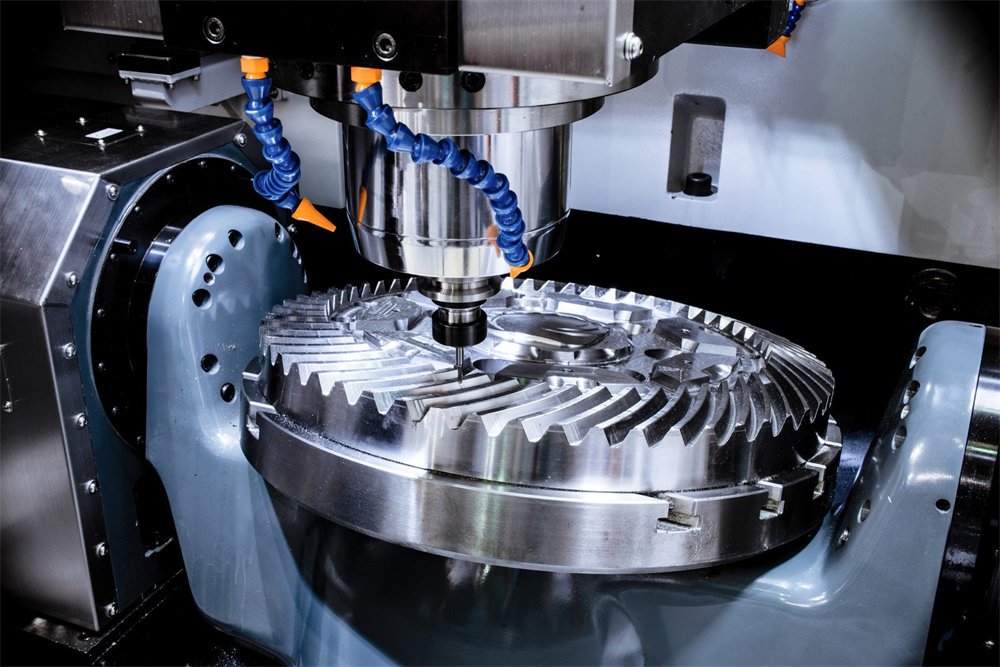

CNC Milling Machines: In contrast, these are used for parts with flat surfaces or intricate contours, such as grooves and complex spatial curves. The tool itself rotates while the workpiece remains fixed, perfect for aerospace parts like engine blades.

Precision in Machining

Precision is another key factor distinguishing these two types of machines.

-

CNC Lathes: They are capable of achieving extremely tight tolerances in diameter and surface finish due to their stability during rotation. For example, shaft parts can be manufactured with tolerances as tight as ±0.01mm.

-

CNC Milling Machines: While also precise, these machines require careful programming and tool path planning to maintain accuracy, especially during multi-axis operations. Modern CNC milling can achieve tolerances around ±0.05mm, suitable for mold manufacturing.

Efficiency and Workflow

Efficiency in machining also varies between these machines based on the task.

-

CNC Lathes: These machines excel in producing high volumes of rotational parts quickly, with minimal tool changes. Their efficiency is evident in batch processing of similar components.

-

CNC Milling Machines: Their strength lies in handling complex shapes, though frequent tool changes for different features can affect speed. Optimized programming can mitigate this, enhancing efficiency even for intricate designs.

Industry Applications

The choice between these machines often depends on the industry requirements.

-

CNC Lathes: Widely used in automotive and mechanical hardware industries, they are crucial for manufacturing parts like wheel hubs and tool handles.

-

CNC Milling Machines: Essential in mold making and aerospace, they handle the intricate designs of mold cavities and aircraft components with precision.

Understanding these differences allows manufacturers to select the right machine based on specific project needs, ensuring optimal performance and cost-effectiveness.

CNC lathes are best for flat surfaces.False

CNC lathes are optimized for cylindrical parts, not flat surfaces.

Milling machines handle complex contours.True

CNC milling machines excel at machining intricate shapes and contours.

How Do Precision Levels Compare in CNC Lathes vs. Milling Machines?

Precision is crucial in CNC machining, impacting product quality and efficiency. How do lathes and milling machines stack up?

CNC lathes offer exceptional precision in machining rotational parts, achieving diameter tolerances as tight as ±0.01mm. In contrast, CNC milling machines excel in precision for complex shapes and planes, with tolerances reaching ±0.05mm, depending on the machine and tooling used.

Understanding Precision in CNC Lathes

CNC lathes are renowned for their ability to maintain high precision when crafting rotational parts. This capability is largely due to the rotational stability of the workpiece, which minimizes deviations during the machining process. For example, precision shafts in automotive applications often require stringent diameter tolerances that CNC lathes can handle with ease.

The key to achieving such accuracy lies in the lathe’s ability to control both the external and internal diameters of the workpiece. With advanced tool path planning and programming, CNC lathes can maintain a dimensional tolerance as tight as ±0.01mm. Additionally, the surface finish achieved by CNC lathes is typically superior due to the consistent rotational speed of the workpiece, which reduces surface roughness significantly.

Precision Capabilities of CNC Milling Machines

On the other hand, CNC milling machines are designed to handle complex shapes and surfaces, offering precision that is equally impressive but more challenging to achieve. The precision in milling machines is heavily reliant on multiple factors: the inherent accuracy of the machine itself, the quality of the cutting tools used, and the skill in programming tool paths.

While handling complex geometries such as mold cavities or aerospace components like engine blades, CNC milling machines can achieve dimensional precisions within ±0.05mm. This level of precision is particularly crucial in industries where intricate designs and fine details are paramount.

Comparative Analysis

| Aspect | CNC Lathes | CNC Milling Machines |

|---|---|---|

| Part Types | Rotational (e.g., shafts) | Complex shapes (e.g., molds) |

| Typical Tolerance | ±0.01mm | ±0.05mm |

| Surface Finish | Superior due to rotation | Varies with toolpath planning |

| Programming | Relatively straightforward | More complex for multi-axis |

The table above highlights the core differences in precision capabilities between the two types of CNC machines.

For those seeking further insight into which machine suits specific needs, exploring resources on CNC machine programming2 can offer valuable guidance on optimizing precision based on machining requirements.

CNC lathes achieve tighter tolerances than milling machines.True

CNC lathes can achieve tolerances as tight as ±0.01mm, tighter than milling.

Milling machines handle rotational parts better than lathes.False

CNC lathes are specialized for rotational parts, unlike milling machines.

Which Industries Benefit Most from CNC Lathes and Milling Machines?

Industries from automotive to aerospace are transforming their processes with CNC lathes and milling machines, optimizing precision and efficiency.

CNC lathes benefit the automotive and mechanical hardware industries by efficiently machining rotational parts. Conversely, CNC milling machines are pivotal in mold manufacturing and aerospace for creating intricate shapes and surfaces. These tools enhance precision and production efficiency across diverse sectors.

Automotive Industry

In the automotive sector, CNC lathes3 are indispensable for producing high-precision rotational parts like shafts and wheel hubs. The ability to maintain tight tolerances and smooth finishes makes them ideal for components requiring durability and performance consistency. Additionally, the mass production of these parts benefits from the efficiency of CNC lathes, reducing production times and costs.

On the other hand, CNC milling machines4 play a crucial role in crafting complex engine components that demand intricate geometries. Their capability to handle non-rotational parts with precision is vital in enhancing vehicle performance and innovation in engine design.

Aerospace Industry

The aerospace sector heavily relies on CNC milling machines due to their ability to create complex shapes, such as aircraft wings and turbine blades, with high precision. The industry’s stringent standards for safety and performance necessitate components that can withstand extreme conditions, which is achievable through advanced milling techniques.

CNC lathes also contribute by manufacturing axially symmetric parts like connecting rods and landing gear components, where precise dimensions and flawless surfaces are critical.

Mold Manufacturing

Mold manufacturing demands precision and complexity that CNC milling machines5 excel at delivering. These machines can create detailed mold cavities and cores essential for producing intricate plastic parts. The high level of accuracy ensures that every mold produced maintains consistency, a critical factor in maintaining product quality across batches.

Mechanical Hardware Industry

In the mechanical hardware sector, CNC lathes are widely used to machine handles, fasteners, and other rotational components. Their efficiency in producing uniform parts with minimal tool changes enhances productivity and reduces waste, making them a staple in hardware production.

In summary, each industry benefits uniquely from CNC technology. The choice between lathes and milling machines depends on the specific demands of the parts being manufactured, whether rotational or non-rotational, simple or complex.

CNC lathes are crucial in automotive for rotational parts.True

CNC lathes efficiently machine high-precision rotational parts like shafts.

CNC milling machines are not used in aerospace.False

They are essential for creating complex shapes like wings and blades.

What Should You Consider When Investing in CNC Machinery?

Investing in CNC machinery requires careful consideration of factors like cost, precision, and industry needs. Choosing the right machine can greatly enhance productivity and efficiency.

When investing in CNC machinery, consider factors such as cost, precision requirements, material compatibility, and specific industry applications. Evaluating these elements ensures alignment with your manufacturing goals and maximizes return on investment.

Cost and Budget Considerations

CNC machinery can be a significant investment, and understanding the cost implications is crucial. Consider the initial purchase price, but also evaluate long-term costs such as maintenance, operational expenses, and potential upgrades.

- Initial Costs: CNC machines can vary widely in price depending on their capabilities, size, and brand. It’s essential to balance the cost with the features that align with your specific needs.

- Operational Costs: Energy consumption and routine maintenance can add up over time. Calculate these expenses to ensure they fit within your budget.

- Return on Investment (ROI): Determine how quickly the machine will pay for itself through increased productivity and reduced labor costs.

Precision and Tolerances

Different industries have varying demands for precision. Identifying the level of precision required for your projects helps in selecting the appropriate machine.

- Precision Requirements: Some industries, like aerospace or medical devices, require extremely tight tolerances. Assess whether the machine meets these standards consistently.

- Accuracy Maintenance: Consider how the machine maintains its accuracy over time and under different working conditions.

Material Compatibility

Not all CNC machines handle every material effectively. Understanding the materials you plan to work with ensures compatibility.

- Material Variety: From metals to plastics, different materials require different tools and machine capabilities. Confirm that the CNC machine can handle your specific materials efficiently.

- Tooling Options: Check if the machine supports a range of tooling options suitable for your materials.

Industry-Specific Applications

The needs of your industry greatly influence which CNC machine is best suited for your operations.

- Industry Needs: Whether you’re in automotive, aerospace, or mold-making, each sector has unique demands that a particular type of CNC machine might meet better than others. Explore industry-specific CNC applications6 to ensure alignment with your sector’s requirements.

- Future-Proofing: Consider potential future needs as industries evolve. A machine that can adapt to new technologies or increased production demands may offer better value in the long run.

Technology and Features

Modern CNC machines come with various technological advancements that can enhance productivity.

- Software Integration: Ensure the machine integrates well with your existing software systems for seamless operation.

- Automation Capabilities: Look for machines that offer automation features to reduce manual intervention and increase efficiency.

Investing in CNC machinery is a decision that requires careful analysis of these factors. By understanding the intricacies of cost, precision, material compatibility, industry needs, and technology, you can make an informed choice that aligns with your business objectives.

CNC machines are cost-effective for all industries.False

Not all industries will find CNC machines cost-effective due to varied needs.

Material compatibility is crucial in choosing CNC machinery.True

Ensuring material compatibility maximizes efficiency and machine performance.

Conclusion

Choosing the right CNC machine hinges on your unique project needs. Reflect on your requirements to ensure optimal performance.

-

Explore how CNC lathes excel at precision in rotational machining.: Versatility: Automated CNC lathe machining is very versatile, it can produce almost any type of part or product, from medical devices to auto … ↩

-

Gain insights on optimizing precision through effective CNC programming techniques.: Unlock tips and tricks for generating productive CNC programs. Improve efficiency, precision, and workflow in your machining processes with … ↩

-

Explore how CNC lathes optimize automotive part production.: CNC benefits span from increased production speeds to heightened precision, each contributing significantly to the industry’s efficiency and … ↩

-

Understand the critical contributions of CNC milling in aerospace.: Aerospace CNC machining involves using computer-aided tools and components to produce and maintain aircraft and space parts. ↩

-

Discover how CNC milling ensures precision in mold making.: CNC machining is the leading production style for mold making. Molds are most commonly machined out of tool steel and stainless steel, but aluminum is also … ↩

-

Discover how CNC machines cater to diverse industry needs effectively.: Discover the top industries using CNC machinery like medical, aerospace, and more. Learn about CNC material selection and custom components … ↩