Ever wondered why Gweike lasers come with a hefty price tag?

Gweike lasers are expensive due to their advanced technology, high precision, and robust build quality. They offer unique features such as enhanced cutting speed and superior accuracy, setting them apart from other brands.

While understanding the initial cost is crucial, diving deeper into what makes Gweike lasers unique will reveal why many users find them worth the investment. Let’s explore the distinctive features and benefits that justify their premium pricing.

Gweike lasers use CO2 technology for cutting.False

Gweike lasers primarily utilize fiber laser technology, not CO2.

What Advanced Technologies Do Gweike Lasers Utilize?

Curious about the cutting-edge technology behind Gweike lasers?

Gweike lasers utilize advanced technologies such as fiber laser systems, AI-driven automation, and precision control software to deliver superior performance and versatility across various applications.

Fiber Laser Systems

Fiber laser technology is a cornerstone of Gweike’s offerings, providing high precision and efficiency. Unlike traditional CO2 lasers, fiber lasers have a longer lifespan and require less maintenance. This technology enables faster cutting speeds and better energy efficiency, making it ideal for industrial applications.

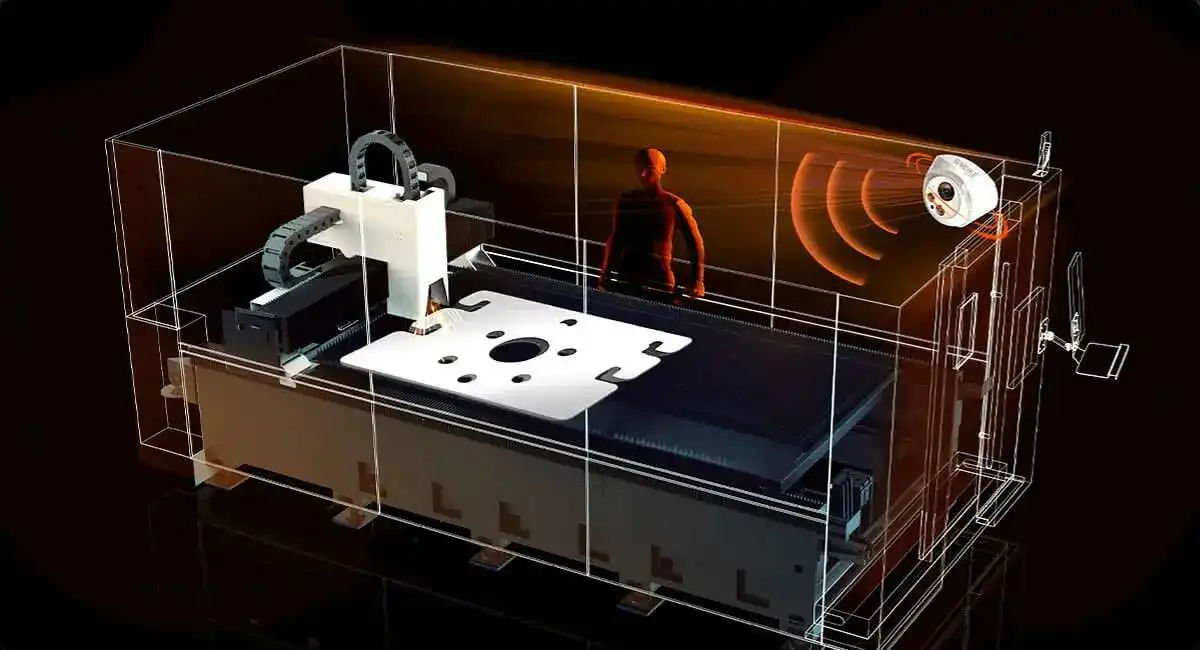

AI-Driven Automation

Gweike integrates artificial intelligence to enhance operational efficiency. The use of AI algorithms optimizes the cutting process by automatically adjusting settings for different materials and thicknesses. This reduces manual intervention, resulting in higher productivity and reduced error rates.

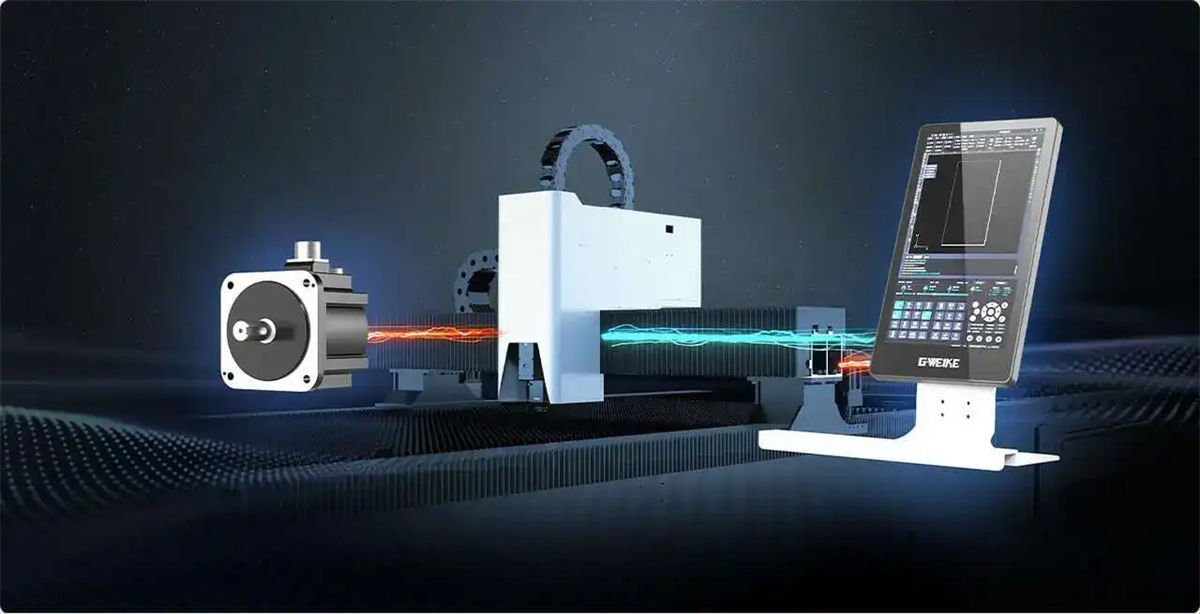

Precision Control Software

The control software used in Gweike lasers allows for meticulous customization of cutting paths and patterns. This precision is crucial in industries requiring intricate designs and minimal material wastage. The software also offers real-time monitoring and diagnostics, which help in maintaining consistent quality output.

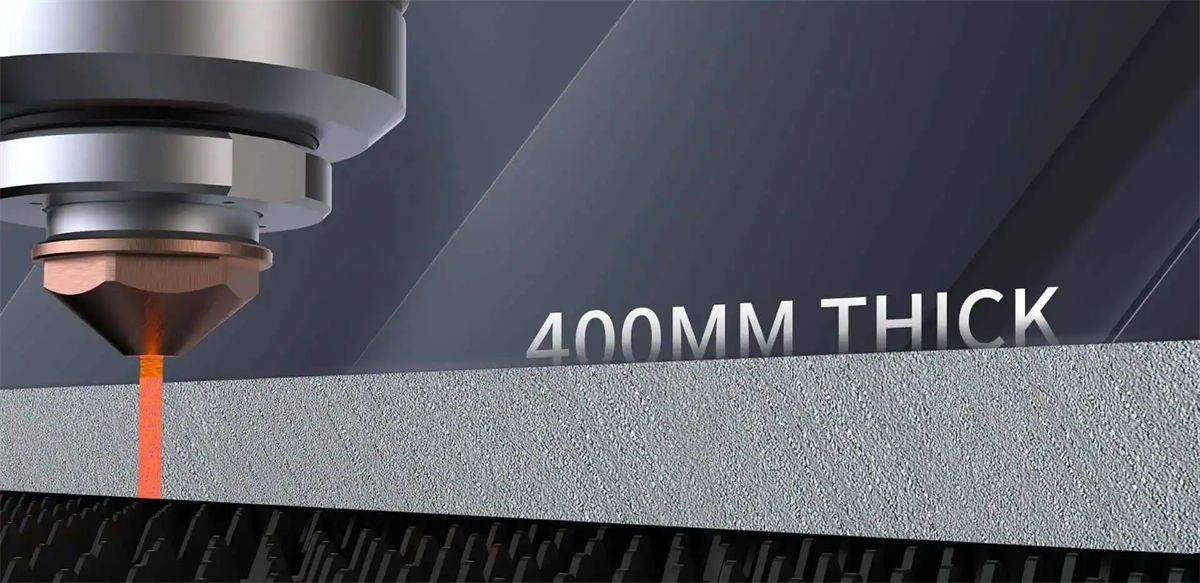

Versatile Cutting Capabilities

One of the standout features of Gweike lasers is their ability to cut a wide range of materials including metals, plastics, and composite materials. The flexibility provided by their advanced technology supports diverse industry needs—from automotive to aerospace.

| Feature | Description |

|---|---|

| High-Speed Cutting | Allows for quick processing of materials, reducing lead times significantly. |

| Material Versatility | Handles various types of materials without compromising on quality. |

| Energy Efficiency | Fiber technology ensures lower energy consumption compared to traditional methods. |

By leveraging these advanced technologies1 and features, Gweike lasers position themselves as a leading choice for industries demanding precision and efficiency in their manufacturing processes.

Gweike lasers use CO2 technology for cutting.False

Gweike lasers utilize fiber laser technology, not CO2.

AI optimizes Gweike's cutting process.True

AI algorithms adjust settings for materials, boosting efficiency.

How Do Gweike Lasers Compare to Other Brands?

In the competitive world of laser technology, how does Gweike stand against its rivals?

Gweike lasers distinguish themselves with superior technology, competitive pricing, and exceptional customer support. Their blend of innovation and affordability places them ahead in the market, making them a preferred choice for various industries.

Technology and Innovation

Gweike lasers are renowned for their cutting-edge technology. They integrate features like auto-focus capabilities, dual-drive motors, and intelligent software that enhance precision and efficiency. While many brands offer similar technologies, Gweike’s implementation often results in faster processing speeds and greater reliability. This makes them particularly suitable for industries requiring high accuracy and productivity, such as advanced manufacturing2.

Cost Versus Quality

When comparing costs, Gweike lasers offer a competitive edge. Despite their advanced features, they are priced reasonably compared to other high-end brands like Epilog or Trotec. This cost-effectiveness does not compromise quality, as Gweike maintains stringent standards in manufacturing, ensuring robust build quality that stands the test of time.

| Feature | Gweike | Competitor A | Competitor B |

|---|---|---|---|

| Auto-Focus | Yes | No | Yes |

| Dual-Drive Motor | Yes | Yes | No |

| Price Range | $$ | $$$ | $$ |

Customer Support and Service

Another standout aspect of Gweike lasers is their exceptional customer service. They provide comprehensive support packages, including installation guidance, troubleshooting, and regular maintenance updates. Many users appreciate the ease of access to support resources3, a feature that some competitors lack.

Brand Reputation and Feedback

Gweike has garnered a reputation for reliability and user satisfaction, often reflected in positive reviews and feedback from industry professionals. While brands like Glowforge are praised for their user-friendly interfaces, Gweike’s appeal lies in its balance of performance and ease of use, making it a strong contender in the laser technology market.

Gweike lasers have auto-focus capabilities.True

Gweike integrates auto-focus in their lasers, enhancing precision.

Competitor A offers dual-drive motors in their lasers.True

Competitor A provides dual-drive motors, similar to Gweike.

Are There Specific Industries Where Gweike Lasers Excel?

Discover the industries where Gweike lasers shine the brightest, showcasing their unmatched capabilities.

Gweike lasers excel in industries like automotive, aerospace, and signage due to their precision, speed, and ability to handle complex materials efficiently.

Automotive Industry

The automotive sector heavily relies on precision and efficiency, making Gweike lasers an ideal choice. Their ability to cut and engrave with extreme accuracy ensures that automotive components fit perfectly, enhancing vehicle safety and performance. Gweike lasers handle a variety of materials, including metals and plastics, which are commonly used in automotive manufacturing.

Aerospace Applications

In the aerospace industry, the demand for high-precision components is paramount. Gweike lasers offer superior cutting speed and precision, crucial for creating intricate parts used in aircraft. The ability to work with lightweight materials such as titanium and aluminum without compromising quality makes them a valuable tool in this field.

Signage and Advertising

The signage industry benefits significantly from the flexibility of Gweike lasers. Their capability to work with different materials such as acrylic, wood, and metal allows for the creation of eye-catching signs and displays. Enhanced cutting speed translates into faster production times, helping businesses meet tight deadlines.

Textile and Fashion

Gweike lasers are increasingly popular in the textile industry due to their ability to cut fabrics with precision and speed. This technology enables designers to create intricate patterns and designs that would be difficult to achieve using traditional methods. The non-contact process also ensures that delicate fabrics are not damaged during cutting.

Table: Industry Applications of Gweike Lasers

| Industry | Material Examples | Benefits |

|---|---|---|

| Automotive | Metals, Plastics | Precision fitting, Material versatility |

| Aerospace | Titanium, Aluminum | High-precision, Lightweight material handling |

| Signage | Acrylic, Wood, Metal | Flexibility, Fast production |

| Textile & Fashion | Fabrics | Detailed designs, Non-damaging processing |

Exploring these industries highlights how advanced laser technology4 can revolutionize production processes and enhance product quality across various sectors. This versatility is one of the reasons why Gweike lasers maintain a strong foothold in these industries.

Gweike lasers are ideal for cutting fabrics.True

Gweike lasers cut fabrics with precision and speed, ideal for textiles.

Gweike lasers are unsuitable for signage applications.False

They excel in signage by working with materials like acrylic and metal.

What Should You Consider Before Investing in a Gweike Laser?

Investing in a Gweike Laser is a significant decision requiring careful thought and analysis.

Before investing in a Gweike Laser, consider factors such as budget, intended application, required precision, and long-term maintenance costs. Assess these elements to ensure the laser aligns with your business needs and growth strategy.

Determine Your Budget and Financial Plan

Investing in a high-quality laser like those from Gweike requires a clear understanding of your financial capacity. Assess the initial purchase price, but also account for potential financing options, tax incentives, or leasing arrangements. Consider long-term expenses such as maintenance and potential upgrades to keep the equipment at peak performance.

Evaluate Your Application Needs

Determine what tasks you need the laser to perform. Gweike lasers excel in various industries including manufacturing, automotive, and signage. However, selecting the right model depends on your specific requirements such as material types and thicknesses you frequently work with. List your core needs to match them with the appropriate Gweike model5.

Analyze Required Precision and Speed

Precision and speed are critical metrics that could affect your operational efficiency. Gweike lasers are known for their high precision and fast processing capabilities, making them suitable for intricate designs and high-volume production runs. Consider how these features align with your production goals and whether they provide a competitive advantage over existing solutions.

Consider Long-Term Maintenance and Support

A crucial aspect of any equipment investment is understanding the long-term support and service options. Research Gweike’s after-sales services, availability of spare parts, and technical support. Reliable maintenance can significantly extend the lifespan of your laser, ensuring consistent performance over the years.

Assess Scalability and Future Growth

Finally, consider how the laser fits into your long-term business strategy. Is it scalable with your future growth plans? Evaluate whether the laser can adapt to changing technologies or increased production demands without incurring excessive additional costs. Investing in a Gweike Laser6 should align not only with your current needs but also with future aspirations.

By carefully considering these factors, you can make an informed decision about whether a Gweike Laser is the right investment for your business operations.

Gweike lasers are suitable for all industries.False

Gweike lasers excel in specific industries like manufacturing and signage.

Long-term maintenance is crucial for Gweike lasers.True

Reliable maintenance extends the lifespan and ensures consistent performance.

Conclusion

Gweike lasers combine advanced technology and precision, justifying their price. When choosing a laser cutter, consider these factors to ensure a wise investment.

-

Explore the advantages of fiber lasers in modern manufacturing.: Fiber lasers are highly efficient and consume less power than conventional manufacturing machines. This reduces your carbon footprint and lowers your operating … ↩

-

Discover which industries benefit most from advanced laser features.: Laser processes are becoming the go-to manufacturing technologies for medical device manufacturers as they design smaller and more advanced … ↩

-

Explore user experiences with Gweike’s customer service.: I own a l1390n, machine is fairly good, but the support isn’t great, also they take assumptions on your order, their English isn’t good and even for me that is … ↩

-

Learn how laser technology boosts efficiency and quality in manufacturing.: Using lasers in manufacturing can lead to shorter cycle times, less maintenance, and more cost-effective production. ↩

-

Compare various models to find one that suits your needs.: The Gweike machine is also extremely competitively priced (~$3150) versus Glowforge, even before you take into account that you get a filter for free which is … ↩

-

Explore how Gweike Lasers can support business growth.: It has a maximum cutting speed of 100m/min, positional accuracy of approximately ±0.03mm, and high repeatability (±0.02mm). All these features, … ↩