Have you ever found yourself scratching your head at the price of Amada lasers? You’re not alone!

Amada lasers are expensive due to their cutting-edge technology, exceptional build quality, and unparalleled operational efficiency. These factors ensure superior performance and longevity, justifying the initial investment compared to other laser cutting options.

But hold on! Before we dismiss them as just another overpriced machine, let’s dive into what really makes Amada lasers a worthy investment. You might be surprised by the unique value they offer compared to competitors like Bystronic and Trumpf.

Amada lasers use CO2 technology for cutting.False

Amada lasers utilize advanced fiber laser technology, not CO2.

What Technology Does Amada Use in Their Lasers?

Amada’s laser technology is renowned for its precision, speed, and innovation. What sets it apart?

Amada employs advanced fiber laser technology, automation systems, and intuitive software solutions to enhance precision, efficiency, and versatility in laser cutting applications.

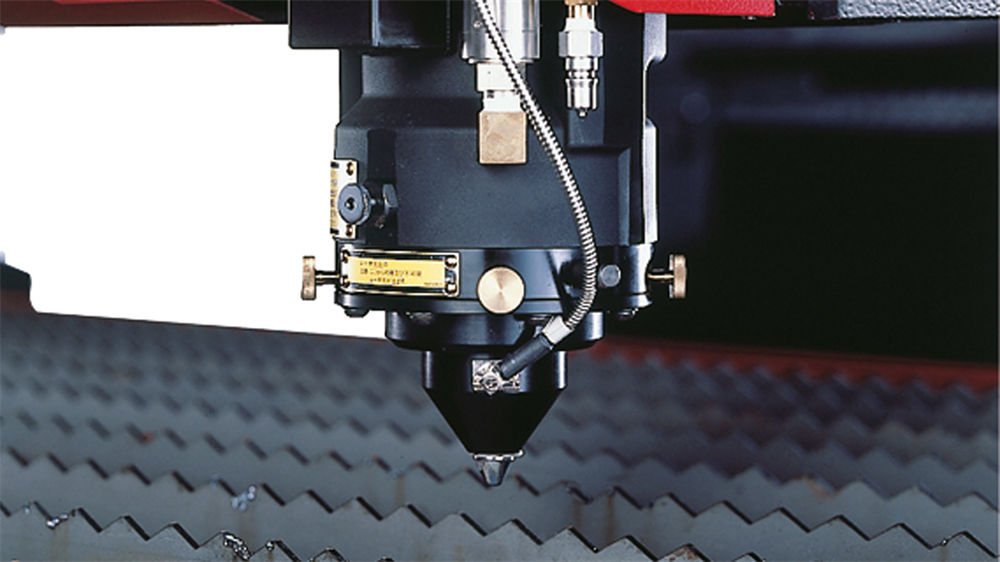

Fiber Laser Technology

Amada’s fiber laser technology is at the forefront of their innovation. Unlike traditional CO2 lasers, fiber lasers offer higher efficiency and require less maintenance due to fewer moving parts. This technology allows for faster cutting speeds and higher precision in cutting various materials, from thin sheets to thicker metals. This advancement translates into reduced operational costs and increased productivity for businesses.

Automated Systems

Automation plays a crucial role in the efficiency of Amada’s laser systems. Their automated material handling solutions streamline the cutting process by minimizing manual intervention, leading to faster cycle times and reduced labor costs. For instance, the ASF-EU Series1 allows seamless integration with existing systems, enhancing flexibility and operational efficiency. These systems ensure consistent quality and reliability in mass production environments.

Software Integration

Amada integrates advanced software solutions into their laser systems to enhance usability and precision. Software like VPSS 3i Blank2 optimizes cutting paths, reduces material waste, and improves overall productivity. The intuitive interface allows operators to easily manage complex cutting jobs, ensuring minimal downtime and maximizing output.

Eco-Friendly Innovations

Sustainability is a growing concern in manufacturing, and Amada addresses this with eco-friendly innovations. Their fiber lasers consume significantly less energy than traditional options, reducing the carbon footprint. Furthermore, their machines are designed for longevity and recyclability, contributing to a more sustainable manufacturing process.

Versatility Across Applications

Amada lasers are designed to cater to a wide range of applications, from automotive to aerospace industries. Their adaptability to different materials and thicknesses makes them a versatile choice for manufacturers. This adaptability is bolstered by Amada’s ENSIS Technology3, which automatically adjusts beam profiles for optimized cutting across various thicknesses, ensuring consistent results across diverse projects.

Amada uses CO2 lasers for high precision cutting.False

Amada employs fiber lasers, not CO2, for higher efficiency and precision.

Amada's fiber lasers reduce operational costs.True

Fiber lasers require less maintenance and offer faster cutting speeds.

How Does Amada Compare to Other Laser Brands?

When evaluating laser brands, Amada stands out for its advanced features and reliability. How does it stack up against competitors?

Amada lasers are renowned for their precision, efficiency, and durability, often surpassing other brands like Bystronic and Trumpf in terms of technological advancement and user satisfaction. Their machines offer unique features that enhance productivity, making them a preferred choice for many industries.

Technological Advancements in Amada Lasers

Amada lasers are equipped with state-of-the-art technology that includes advanced fiber optics and innovative control systems. These components significantly enhance cutting speed and precision, allowing for intricate designs with minimal material waste. Amada’s proprietary software4 further optimizes performance by enabling seamless integration with other manufacturing systems.

Build Quality and Durability

One of the most distinguishing factors of Amada lasers is their robust build quality. The machines are constructed using high-grade materials that ensure longevity and resilience in demanding industrial environments. Compared to other brands like Bystronic, which focus on flexibility and Trumpf, known for their versatility, Amada’s dedication to durability gives them a competitive edge.

Operational Efficiency and Cost-Effectiveness

Despite their higher initial cost, Amada lasers offer exceptional operational efficiency. Their energy-efficient designs reduce power consumption, resulting in lower operational costs over time. This efficiency can lead to substantial savings and a faster return on investment compared to alternatives. For instance, while Trumpf machines are praised for their adaptability, they might not match the energy efficiency of Amada models.

Customer Support and User Satisfaction

Amada is also noted for its excellent customer support. They provide comprehensive training programs and responsive maintenance services, ensuring that users can maximize the potential of their equipment. This support is a significant factor in user satisfaction, setting Amada apart from competitors like Bystronic, which may offer fewer post-purchase services.

In conclusion, while brands like Bystronic and Trumpf have their unique strengths, Amada’s focus on technology, build quality, and support make it a top choice for those seeking long-term value in laser cutting solutions.

Amada lasers are more durable than Bystronic.True

Amada uses high-grade materials, ensuring longevity in industrial settings.

Trumpf lasers are more energy-efficient than Amada.False

Amada's designs reduce power consumption, offering better energy efficiency.

What Are the Long-Term Benefits of Investing in Amada Lasers?

Investing in Amada lasers promises impressive long-term benefits for manufacturers.

The long-term benefits of investing in Amada lasers include increased productivity, reduced operational costs, and enhanced precision. These machines are built to last, providing consistent performance and minimizing downtime. This leads to higher ROI over time, making them a strategic asset for any manufacturing business.

Enhanced Productivity and Efficiency

One of the key long-term benefits of investing in Amada lasers5 is the substantial boost in productivity. These machines are designed to operate at high speeds with precision, allowing manufacturers to increase output without sacrificing quality. The advanced technology integrated into Amada lasers enables seamless operation, significantly reducing the time required for setup and adjustments.

For example, their proprietary laser source technology ensures consistent beam quality and energy efficiency, which translates into faster cutting speeds and more precise results. This technological advantage not only accelerates production cycles but also allows manufacturers to handle complex cutting tasks with ease.

Cost Reduction and Operational Savings

Another major benefit is the reduction in operational costs. Amada lasers are known for their durability and reliability, which means less frequent maintenance and lower repair costs over time. The robust build quality minimizes wear and tear, extending the lifespan of the equipment and ensuring that it remains a valuable asset for years to come.

In addition, these lasers often come with energy-saving features that help reduce electricity consumption. This can result in significant cost savings for businesses operating on tight margins. Moreover, the precision of Amada lasers reduces material wastage, further lowering production costs and improving overall profitability.

Superior Precision and Versatility

Amada lasers offer unmatched precision, which is critical in industries that require intricate designs and exact specifications. This precision ensures that each component meets stringent quality standards, reducing the likelihood of errors and rework. As a result, businesses can maintain a high level of customer satisfaction by consistently delivering high-quality products.

Furthermore, Amada lasers are versatile tools capable of handling various materials, from metals to plastics. This versatility allows manufacturers to diversify their product offerings and enter new markets without needing additional machinery investments. By adapting quickly to market demands, companies can stay competitive and maximize their growth potential.

By considering these long-term benefits, it’s clear that investing in Amada lasers is not just about immediate performance but also about securing a sustainable future for manufacturing enterprises.

Amada lasers increase manufacturing productivity.True

Amada lasers enhance productivity by operating at high speeds with precision.

Amada lasers require frequent maintenance.False

They are known for durability, requiring less frequent maintenance.

Are There More Cost-Effective Alternatives to Amada Lasers?

Exploring cost-effective alternatives to Amada lasers can help businesses optimize their budgets without compromising quality.

Yes, there are more cost-effective alternatives to Amada lasers, such as Bystronic and Trumpf. These brands offer competitive features at a lower price point, making them viable options for companies seeking efficient laser cutting solutions without the premium price tag of Amada.

Comparing Cost-Effective Laser Alternatives

When considering alternatives to Amada lasers6, it’s essential to evaluate factors like performance, price, and support. Brands like Bystronic and Trumpf have emerged as strong competitors, offering comparable technology at a fraction of the cost.

Bystronic: Precision and Affordability

Bystronic has carved out a niche by providing high-quality laser cutting machines that balance precision and affordability. Their machines often feature user-friendly interfaces and robust customer support. Additionally, Bystronic’s focus on energy-efficient technology reduces operational costs, making it an attractive option for cost-conscious businesses.

| Feature | Amada Lasers | Bystronic Alternatives |

|---|---|---|

| Price Range | $$$$$ | $$$ |

| Energy Efficiency | High | Very High |

| Customer Support | Excellent | Good |

Trumpf: Advanced Technology at a Lower Cost

Trumpf is another viable alternative, renowned for its innovative solutions in laser technology. Their equipment often integrates advanced automation features that can streamline production processes. While still offering high performance, Trumpf machines typically come at a lower price point than Amada, which can significantly ease the financial burden on smaller enterprises.

It’s crucial for businesses to assess their specific needs, such as cutting speed, precision requirements, and budget constraints, before deciding on an alternative. Investing time in researching these factors will ensure the selected laser cutter meets both current and future demands.

Factors to Consider When Choosing Alternatives

Before transitioning to a different brand, consider factors such as warranty options, maintenance costs, and potential downtime. Additionally, examining the track record of the manufacturer regarding innovation and reliability can provide insights into long-term value.

Exploring these aspects can help determine the best fit for your business operations while ensuring cost-effectiveness. For further comparison on laser cutting technologies and their applications, explore comprehensive guides7.

Bystronic lasers are more affordable than Amada.True

Bystronic offers laser machines at a lower price point than Amada.

Trumpf lasers lack advanced automation features.False

Trumpf integrates advanced automation in their laser equipment.

Conclusion

In summary, Amada lasers command a higher price due to their advanced technology and efficiency. For anyone considering an investment, it’s crucial to assess individual needs against performance and budget to ensure the best choice.

-

Discover how Amada’s automation enhances efficiency and reduces labor costs.: ASF II 3015 EU automated storage solution takes care of automatic loading and unloading of sheets to and from AMADA ‘Flying-Optics’ lasers. ↩

-

Learn about Amada’s software that optimizes cutting paths and reduces waste.: The most advanced Blanking Progamming. VPSS3i Blank is the most advanced and user-friendly blanking solution available for programming your AMADA machine. ↩

-

Understand how ENSIS Technology adapts beam profiles for varied materials.: The ENSIS AJe Series uses AMADA’s proprietary fiber laser technology to process both thin and thick materials without a cutting lens change or manual setup. ↩

-

Explore how Amada’s software enhances laser precision and efficiency.: Digitization Streamlines Processing AMADA offers the key software solutions for the digitalization of metal processing. ↩

-

Discover more about productivity and efficiency benefits with Amada lasers.: The technology in question can be used to handle reflective metals such as copper, is extremely fast and, having few moving parts, requires minimal maintenance. ↩

-

Explore competitors offering similar technology at a lower cost.: Amada laser and tower m/c are much reliable and polished than Bystronic. Also I had great support from amada, on the other hand Bystronic … ↩

-

Discover detailed insights into various laser technologies.: In this guide, we’ll explain what the most common modern laser technologies and processes are, where they’re best applied and how laser cutting compares to … ↩