Discover how laser marking machines can transform your production process!

Laser marking machines from Laser Marking Technologies can efficiently mark a wide variety of materials including metals like stainless steel and aluminum, non-metals such as plastics, glass, ceramics, and even wood. This versatility makes them ideal for applications in industries like automotive, medical devices, electronics, and more.

But that’s just the tip of the iceberg! Let’s delve deeper into how these remarkable machines work and the incredible impact they have across different industries.

Laser marking machines can mark both metal and non-metal materials.True

Laser marking machines are versatile, marking metals like steel and non-metals like glass.

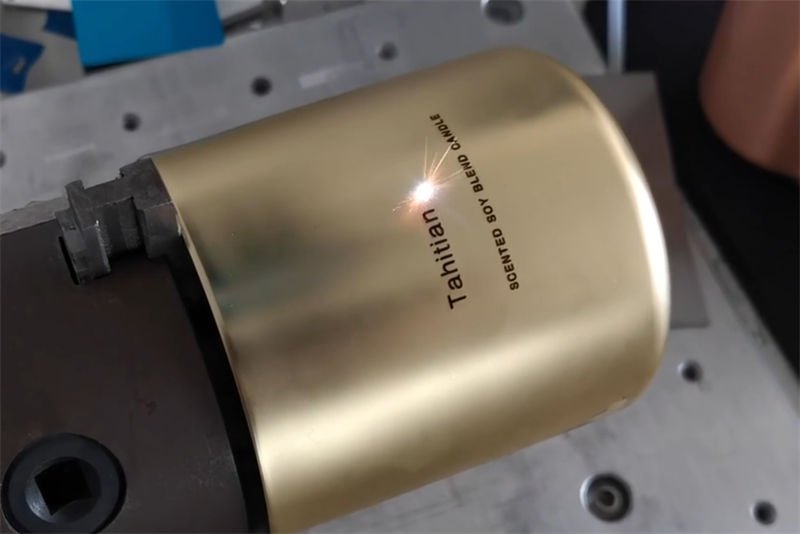

How Do Laser Marking Machines Enhance Metal Marking?

Laser marking machines are transforming the way industries mark metal, offering unmatched precision and longevity in various applications.

Laser marking machines enhance metal marking by providing permanent, high-contrast, and wear-resistant marks without damaging the metal’s surface. This technology is ideal for industries requiring high precision, such as automotive, aerospace, and medical devices.

The Science Behind Laser Marking on Metals

Laser marking machines utilize focused laser beams to alter the surface properties of metals without any physical contact. This process involves either engraving, etching, or annealing, each method imparting a unique effect on the metal surface. For instance, annealing1 creates a mark by oxidizing the metal surface, resulting in a smooth finish with no depth.

Applications in Various Industries

Automotive Industry: In the automotive sector, laser marking is employed to mark components like engine parts with critical information such as serial numbers and production details. This ensures traceability and compliance with quality standards. A typical use case is marking a VIN2 on metal components, which remains legible even under harsh environmental conditions.

Aerospace Industry: Aerospace components require precise and durable markings for identification and compliance purposes. Laser marking offers a non-intrusive solution that maintains the integrity of the component while providing high-resolution markings. This includes marking turbine blades3 with part numbers and maintenance records.

Medical Devices: For medical devices made of stainless steel or titanium, laser marking is essential for engraving critical information such as batch numbers and expiry dates. This process ensures that the marks are corrosion-resistant and do not compromise the sterility of the device.

Advantages Over Traditional Marking Methods

| Feature | Traditional Methods | Laser Marking |

|---|---|---|

| Contact | Required | Non-contact |

| Wear Resistance | Moderate | High |

| Precision | Variable | High |

| Speed | Slower | Faster |

| Environmental | Uses chemicals | Eco-friendly |

Traditional methods like stamping or printing may wear out over time, whereas laser marking offers a permanent solution without using consumables, making it an environmentally friendly choice. The precision of laser technology also allows for intricate designs and information to be marked with minimal distortion.

Future Trends in Metal Marking

As industries evolve towards more automated and digitized processes, laser marking technology is expected to advance with features like integrated AI for quality control and real-time data logging. The advent of 3D laser marking4 is poised to further enhance the capabilities of this technology by allowing for marking on complex geometries and surfaces.

Laser marking is contact-based.False

Laser marking is a non-contact process, enhancing precision and quality.

Laser marking uses consumables.False

Laser marking does not require consumables, making it eco-friendly.

What are the Benefits of Laser Marking on Non-Metal Materials?

Laser marking non-metal materials offers numerous advantages in manufacturing, enhancing both functionality and aesthetics.

Laser marking provides precise, non-contact marking solutions for non-metal materials like plastics, glass, ceramics, and wood. It enhances product traceability, branding, and customization while maintaining material integrity. Its versatility makes it ideal for high-volume production across various industries.

Enhancing Traceability and Branding with Laser Marking

Laser marking on non-metal materials such as plastics5 and ceramics offers unparalleled precision. This precision is essential for applications like marking safety warnings on plastic toys or model numbers on ceramic electronic components. The indelible nature of laser marks ensures long-term traceability and compliance with regulatory standards.

Furthermore, the ability to mark intricate designs and logos aids in robust branding strategies. For example, marking brand logos on glass bottles or personalized patterns on ceramic tableware not only enhances aesthetic appeal but also serves as an anti-counterfeiting measure.

Maintaining Material Integrity

One of the standout benefits of laser marking is its non-contact nature. This means that sensitive materials like glass and wood are not subjected to mechanical stress or thermal distortion during the marking process. For instance, glass surfaces6 used in high-precision optical applications retain their clarity and functionality after laser marking, which is critical for maintaining performance standards.

Similarly, when marking wood, laser technology can achieve varied depths and colors by adjusting laser parameters without compromising the material’s structural integrity. This is particularly beneficial for creating artistic designs on wooden furniture or custom branding on wooden packaging.

Versatility Across Industries

The adaptability of laser marking systems makes them suitable for a wide range of industrial applications. In the automotive sector7, interior plastic components are marked to indicate functionalities and part numbers, ensuring seamless assembly and user interaction. The clear markings withstand environmental stressors like heat and abrasion within the vehicle environment.

In the medical field, laser marking ensures that disposable plastic medical devices are marked with essential information like expiration dates and usage instructions. The precision of laser markings meets stringent safety and quality standards, ensuring patient safety without introducing harmful substances.

| Material | Typical Applications | Benefits |

|---|---|---|

| Plastics | Toys, automotive parts | Fast production speed, durable markings |

| Glass | Bottles, optical devices | High-quality marks without affecting optical properties |

| Ceramics | Electronic components, tableware | Precision marking without performance degradation |

| Wood | Furniture, packaging | Customizable designs with varying depths and aesthetics |

Cost-Effective and Environmentally Friendly

Laser marking is a cost-effective solution for non-metal materials due to its high-speed processing capabilities and minimal maintenance requirements. Unlike traditional methods that rely on consumables like inks or labels, laser systems offer a cleaner alternative, reducing waste and environmental impact.

The packaging industry8 benefits significantly from laser marking as it eliminates the need for inks or chemicals while providing high-speed, accurate markings. This not only reduces production costs but also aligns with eco-friendly manufacturing practices.

Laser marking on glass affects optical properties.False

Laser marking preserves glass clarity, crucial for optical uses.

Laser marking reduces production costs in packaging.True

It eliminates ink use, lowering costs and environmental impact.

How is Laser Marking Applied in the Electronics Industry?

Laser marking has become indispensable in electronics, offering unparalleled precision for marking components and circuit boards.

In the electronics industry, laser marking is applied to semiconductor materials, electronic component housings, and printed circuit boards (PCBs). It ensures precise, non-damaging markings crucial for traceability, quality control, and miniaturization, enhancing the performance and longevity of electronic products.

Precision in Semiconductor Manufacturing

Laser marking is vital for semiconductor materials9, particularly in the manufacturing of silicon wafers. During chip production, laser marking machines leave tiny yet clear markings that include crucial information such as chip models, batch numbers, and production dates. This high-precision marking is essential for chip traceability and quality control. For instance, in the packaging of integrated circuit chips, lasers ensure accurate markings without affecting the chip’s integrity.

Enhancing Electronic Component Housings

Electronic components like resistors, capacitors, and inductors often come with plastic or metal housings. Laser marking offers a solution to engrave component parameters—such as resistance values—and brand logos on these tiny surfaces. This process supports the miniaturization and high-density assembly required in modern electronics. For example, surface-mount components in smartphones benefit from laser marking due to its clarity and wear resistance, ensuring markings remain intact throughout the product’s lifespan.

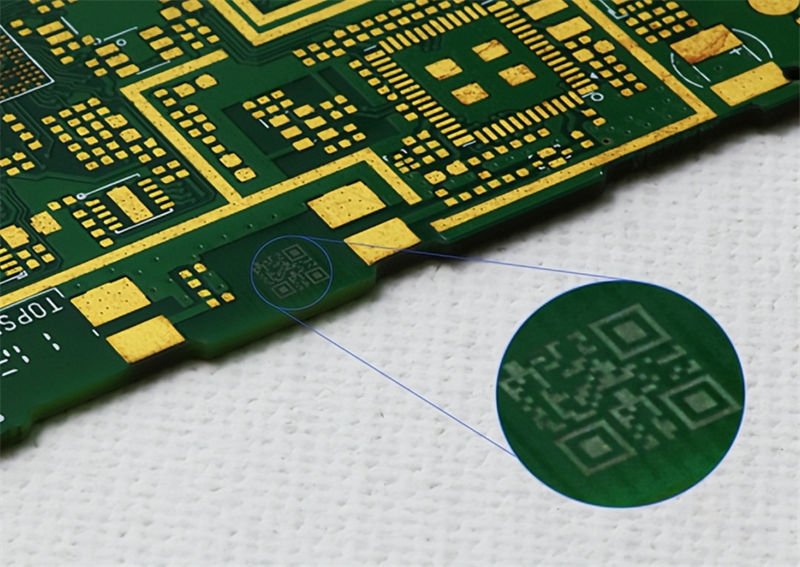

Role in Printed Circuit Boards (PCBs)

In PCB manufacturing10, laser marking is used to inscribe model numbers, layer counts, version numbers, and serial numbers onto circuit boards. Such markings help automated production lines with precise component installation and contribute to quality control. High-precision multilayer PCBs benefit from laser marking as it doesn’t damage circuit traces or internal structures. This capability significantly boosts production efficiency and ensures the longevity of PCB products.

| Application | Laser Marking Benefit |

|---|---|

| Semiconductor Chips | High precision and traceability |

| Component Housings | Miniaturization support and durability |

| PCBs | Non-damaging and efficient production |

Laser marking’s adaptability to various materials and its precise, non-contact nature make it indispensable in the electronics industry. Its use ensures that crucial information remains legible despite miniaturization trends, thereby supporting innovation and maintaining high standards of quality and traceability.

Laser marking damages semiconductor materials.False

Laser marking is non-damaging, preserving semiconductor integrity.

Laser marking aids PCB traceability and quality control.True

It inscribes vital data without harming PCB structures.

Why Choose Laser Marking for Medical Devices?

Laser marking technology is redefining the standards for medical devices, ensuring precision, durability, and safety.

Laser marking is ideal for medical devices due to its precision, non-contact process, and ability to withstand sterilization. It provides permanent, clear markings on metals and plastics, ensuring compliance with regulatory standards and facilitating traceability in healthcare environments.

The Importance of Precision in Medical Device Marking

Medical devices require precise markings for identification, compliance, and traceability. Laser marking offers a non-contact method that prevents any potential surface damage, maintaining the integrity of sensitive medical instruments. This precision ensures that markings are clear, accurate, and compliant with industry regulations11. For example, surgical instruments marked with lasers provide reliable information like device names and specifications without compromising their functionality.

Durability Against Sterilization

Medical devices undergo rigorous cleaning and sterilization processes, often involving high temperatures and chemicals. Laser markings can withstand these conditions due to their resistance to wear and corrosion. Unlike traditional marking methods that may fade or degrade over time, laser markings remain legible and intact, ensuring that crucial information such as batch numbers and expiration dates is always accessible. This durability is particularly important for devices like implantable medical devices, where consistent identification is crucial throughout their lifecycle.

| Material | Laser Marking Benefits |

|---|---|

| Stainless Steel | High contrast, corrosion-resistant |

| Plastics | Non-toxic, durable |

Ensuring Compliance and Traceability

In the medical field, compliance with regulatory standards is paramount. Laser marking provides a reliable solution for meeting these standards by producing clear and permanent markings that aid in device traceability. For instance, implantable devices like artificial joints benefit from laser markings that detail model numbers and implantation dates, facilitating patient treatment tracking12 over time. Furthermore, disposable plastic medical devices marked with lasers ensure accurate identification without introducing harmful substances.

Customization and Flexibility

Laser marking technology allows for customization to meet specific industry requirements. Whether marking intricate designs or detailed text on small surfaces, lasers provide flexibility without sacrificing quality. This adaptability is crucial for a range of medical devices, from large diagnostic equipment housings to minute surgical tools.

Overall, choosing laser marking for medical devices offers a multitude of benefits that enhance safety, compliance, and efficiency within the healthcare sector.

Laser marking is non-contact for medical devices.True

Laser marking doesn't physically touch the device, preventing damage.

Traditional markings are more durable than laser markings.False

Laser markings withstand sterilization better, maintaining durability.

Conclusion

Laser marking stands out as a precise and durable solution for diverse materials. Understanding its applications can enhance operational efficiency and product quality in your industry.

-

Learn how annealing creates smooth marks on metal surfaces.: Laser annealing consists of the slow heating of metals with a laser beam. As the metal is heated, oxygen is diffused below the surface. ↩

-

Discover why VINs are crucial for vehicle identification.: Vehicle Identification Numbers let manufacturers track autos. The VIN helps manufacturers easily identify impacted cars so they may contact … ↩

-

Explore marking techniques for aerospace components.: The MULTI4 Integrated marking system is the ideal solution for marking aircraft blades. This unit was installed in an automated line with a front loading … ↩

-

Understand how 3D laser marking enhances metal applications.: The general mechanism of a 3D laser machine is to mark the workpiece by plotting some points in the 3D design of the workpiece. Afterward, the machine makes … ↩

-

Explore how laser marking improves plastic product quality.: Color change laser marking is an electrical process that reorders or destroys pigmented macromolecules and ensures maximum readability. No material is removed, … ↩

-

Discover why glass marking is precise and reliable.: Laser glass engraving is a highly efficient and economically convenient process for small-scale and mass production. ↩

-

Learn how automotive manufacturing benefits from laser technology.: Laser marking is the primary traceability tool for automotive component manufacturers. All metal and plastic vehicle components require laser marking. ↩

-

Understand eco-friendly advantages in packaging processes.: The Benefits of Laser Marking for Packaging · Efficiency: Laser marking is fast and precise, enabling manufacturers to keep up with production demands. ↩

-

Explore how laser marking enhances traceability and quality control in semiconductors.: Marking. Laser marking machines are used for 2D code marking on IC chips, LED ceramic packaging, silicon wafers, and more. Since the laser marker has an … ↩

-

Discover how laser marking improves PCB manufacturing efficiency and precision.: The laser marking beam is directed across the surface of the substrate just like a pencil on paper to create the marking image. For printed circuit board … ↩

-

Learn about industry regulations ensuring compliance in laser marking medical devices.: Medical laser marking is mandated and regulated by the FDA in the United States and the corresponding medical regulatory bodies in other countries. The FDA has … ↩

-

Understand how laser-marked implants aid in long-term patient treatment monitoring.: Medical laser device marking refers to the process of engraving or permanently marking medical devices with identifying text and/or images. ↩