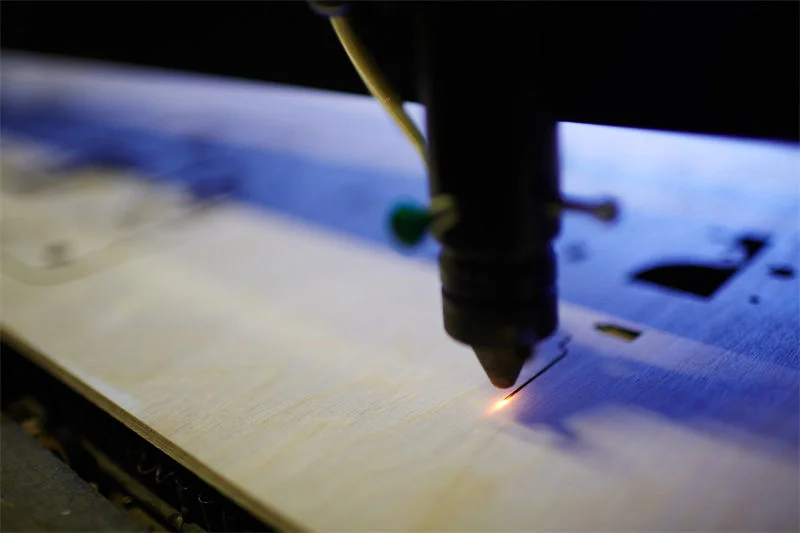

Deciding to invest in a CO2 laser machine feels like stepping into a new world of possibilities. Yet, with that excitement comes a flurry of questions—especially about cost.

CO2 laser machines typically range from $3,850 to $11,999, depending on power (80W to 150W), size (24"x40" to 36"x55"), and additional features like autofocus and built-in chillers. Maintenance and operational costs also factor into the total investment.

But wait! The initial price is just the beginning. Let’s dive deeper into the costs of ownership, including maintenance and potential profitability. This information could save you time and money.

CO2 laser machines cost between $3,850 and $11,999.True

The cost varies based on power, size, and additional features.

What Factors Influence the Price of a CO2 Laser Machine?

Ever wondered why CO2 laser machine prices vary so widely? Let’s dissect the key factors.

The price of a CO2 laser machine is influenced by power output, size, brand, and additional features. Power determines cutting capabilities, with higher wattage costing more. Larger working areas increase costs. Brands with strong reputations command higher prices, and features like autofocus and built-in chillers also add to the cost.

Power and Performance

The wattage of a CO2 laser machine is a critical determinant of its price. Machines with higher wattage, such as those offering 150W compared to 80W, allow for cutting through thicker materials and completing jobs faster. This increased capability generally translates into higher costs.

| Power (Watts) | Material Cutting Capability | Price Impact |

|---|---|---|

| 80W | Thin materials | Lower |

| 150W | Thick materials | Higher |

Size of the Working Area

Another major factor is the size of the working area. Larger machines that can accommodate bigger sheets of material, like a 36"x55" area, are more expensive than smaller models like 24"x40". The size not only influences the machine’s versatility but also its price.

Brand Reputation

Brand plays a significant role as well. Well-known brands often offer superior build quality, reliability, and after-sales service, justifying their premium pricing. However, opting for lesser-known brands can reduce costs by nearly 40% while potentially sacrificing some support and quality assurance.

Additional Features

Features such as autofocus systems, built-in chillers, or enhanced software packages can significantly elevate the price. These add-ons improve efficiency and ease of use, making them attractive for professional settings where time and precision are paramount.

- Autofocus: Automatically adjusts focus for varying material thicknesses.

- Built-in Chillers: Keeps the laser cool during extended operations.

Maintenance and Operational Costs

Long-term ownership involves considering maintenance and operational costs as well. Routine maintenance, energy consumption, and parts replacement are ongoing expenses that should be factored into the total cost of ownership. For example, maintenance costs1 could vary based on usage intensity and environmental conditions, affecting the overall investment value.

Understanding these factors helps potential buyers make informed decisions by aligning their choices with their specific needs and budget constraints.

Higher wattage CO2 lasers cost more due to better cutting capabilities.True

Higher wattage allows cutting thicker materials, increasing costs.

Larger working areas in CO2 lasers reduce the machine's price.False

Larger working areas increase versatility and cost of machines.

How Do Maintenance Costs Affect Your Investment?

Maintenance costs can significantly impact the overall investment in CO2 laser machines, influencing long-term profitability.

Maintenance costs for CO2 laser machines include accessory upkeep, gas refills, and energy consumption. These recurring expenses can accumulate over time, affecting the return on investment. Understanding these costs helps in budgeting for long-term use and assessing the machine’s true value.

Understanding Maintenance Expenses

When purchasing a CO2 laser machine, it’s essential to factor in maintenance expenses alongside the initial purchase price. These costs can include regular servicing, replacement of parts, and unexpected repairs.

Accessory Maintenance

The accessory maintenance of CO2 laser machines involves components like focusing mirrors, nozzles, and reflectors. Typically, accessory maintenance costs around 3000 yuan annually. However, this can vary depending on the machine’s usage intensity and environment. A key consideration is that improper use or harsh operating conditions can increase these costs.

| Accessory | Typical Cost per Year (Yuan) |

|---|---|

| Mirrors | 2000 |

| Nozzles | 500 |

| Reflectors | 500 |

Laser Gas Refills

CO2 lasers require a medium gas to generate the laser beam. Gas refilling is typically needed every 36 months, with each refill costing approximately 5000 yuan. This periodic expense is crucial for maintaining optimal laser performance.

Energy Consumption

A significant portion of the maintenance cost is attributed to energy consumption. A standard 3000W CO2 laser consumes about 30kW, leading to an operational cost of around 21 yuan/hour based on current electricity prices.

Comparing Costs

To provide a clearer picture of how maintenance affects your investment, consider comparing these expenses with fiber lasers, which generally have lower maintenance requirements. Fiber lasers do not require gas refills and often have longer-lasting components, making them a cost-effective alternative in terms of ongoing expenses.

In conclusion, understanding the maintenance costs2 associated with CO2 laser machines is crucial for evaluating the total cost of ownership. These expenses not only affect the initial outlay but also influence long-term profitability and operational efficiency.

CO2 laser machines require gas refills every 36 months.True

Gas refills are necessary for CO2 lasers to maintain optimal performance.

Fiber lasers require more frequent maintenance than CO2 lasers.False

Fiber lasers generally have lower maintenance needs compared to CO2 lasers.

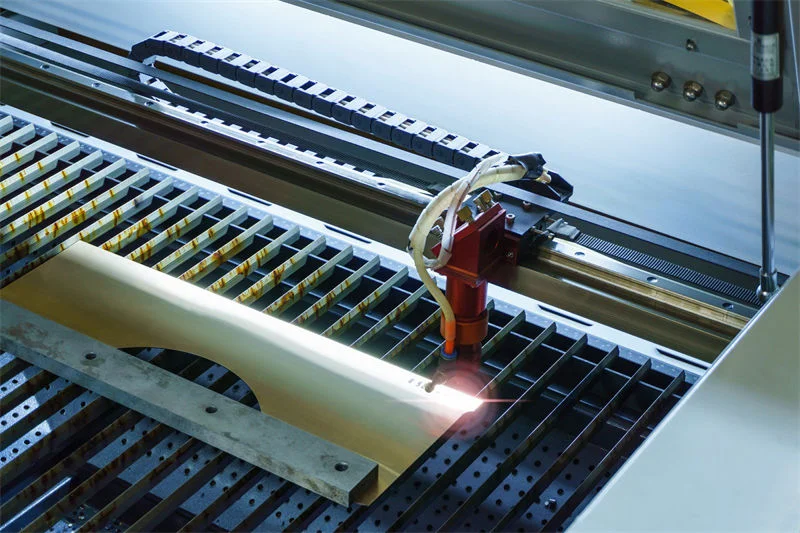

What Are the Operational Costs of a CO2 Laser Machine?

Understanding the operational costs of a CO2 laser machine is crucial for budgeting and optimizing profitability.

The operational costs of a CO2 laser machine include energy consumption, maintenance, consumables, and routine inspections, averaging around 38.3 yuan/hour. Energy use is significant, with electricity costs for the laser and water cooler adding up, while consumable parts and periodic checks further impact expenses.

Energy Consumption

One of the primary components of the operational cost for a CO2 laser machine is energy consumption. A typical 3000W CO2 laser consumes about 30kW of electricity. When factoring in an average electricity price of 1 yuan/kWh and a load factor of 70%, this equates to approximately 21 yuan/hour. Additionally, the water cooler required for the machine consumes 18kW, resulting in an extra 12.8 yuan/hour. This energy demand underscores the importance of considering energy efficiency3 when evaluating operational costs.

Consumables and Maintenance

While CO2 lasers do not use consumables like ink or toner, they do have other material costs. Consumable items include focusing mirrors, ceramics, nozzles, and reflectors, costing about 2.5 yuan/hour. Moreover, CO2 lasers use a medium gas to produce laser light, adding another 1 yuan/hour to the cost.

Routine maintenance is essential for optimal performance. Inspections are typically carried out every 3000 hours (routine) and every 6000 hours (in-depth), costing about 2 yuan/hour. These checks ensure that the machine functions correctly and reduces downtime.

Table: Breakdown of Operational Costs

| Component | Cost (yuan/hour) |

|---|---|

| Electricity (Laser) | 21 |

| Electricity (Cooler) | 12.8 |

| Consumables | 2.5 |

| Medium Gas | 1 |

| Maintenance | 2 |

| Total | 38.3 |

Impact on Business

Understanding these operational costs is vital for businesses considering investing in a CO2 laser machine. While the initial purchase4 provides a baseline cost, ongoing operational expenses significantly affect the total cost of ownership. Businesses must factor in these costs when calculating potential return on investment (ROI) to ensure the machine’s profitability aligns with their financial goals.

CO2 laser machines are popular for their precision and versatility, but understanding their comprehensive costs is essential for maximizing benefits and minimizing unforeseen expenses.

A CO2 laser machine uses 30kW of electricity.True

A typical 3000W CO2 laser consumes about 30kW of electricity.

Consumables cost 5 yuan/hour for CO2 lasers.False

Consumables cost about 2.5 yuan/hour, not 5 yuan/hour.

Is Investing in a CO2 Laser Machine Profitable?

CO2 laser machines promise high precision and versatility, but is the investment truly profitable?

Investing in a CO2 laser machine can be profitable if you strategically manage upfront costs, maintenance expenses, and operational efficiency. It requires a comprehensive analysis of your production needs, market demand, and cost-saving opportunities over time.

Understanding the Financial Dynamics

Investing in a CO2 laser machine involves several financial considerations. The initial purchase price varies significantly based on factors such as power and additional features, ranging from $3,850 to $11,999. However, the initial cost is just the tip of the iceberg.

Ongoing Costs Analysis

-

Maintenance Costs: Regular maintenance is crucial for optimal performance and longevity. Annually, you might incur approximately 3,000 yuan for accessory maintenance. Periodic gas charging every 36 months adds another 5,000 yuan to your expenses.

-

Operational Expenses: A 3000W CO2 laser consumes about 30kW of electricity per hour, costing around 21 yuan/hour. Add the water cooler consumption (18kW) at 12.8 yuan/hour and other consumables such as mirrors and nozzles, costing roughly 2.5 yuan/hour.

These expenses can add up quickly but are often offset by the machine’s productivity benefits.

Weighing the Benefits Against Costs

The profitability of a CO2 laser machine depends largely on its application within your business operations. Here are some critical benefits:

- Precision and Efficiency: CO2 lasers offer high precision, enabling intricate designs and reducing material waste. This efficiency can lead to cost savings over time.

- Versatility: These machines can handle various materials like wood, acrylic, and metal, expanding your product offerings and market reach.

- Low Consumable Costs: Unlike other machines, CO2 lasers have relatively low consumable costs, enhancing their long-term profitability.

Analyzing Market Demand and Business Needs

To ensure profitability, analyze the market demand for your products and services. A well-defined target market can help you maximize the machine’s potential output.

Additionally, consider your current production capacity. If your existing equipment struggles to meet demand, a CO2 laser could boost productivity significantly.

In summary, while the upfront and ongoing costs of a CO2 laser machine5 may seem daunting, strategic management and alignment with business goals can render the investment lucrative in the long run.

CO2 laser machines cost between $3,850 and $11,999.True

The initial purchase price of CO2 laser machines varies within this range.

3000W CO2 lasers consume 50kW of electricity per hour.False

A 3000W CO2 laser actually consumes about 30kW per hour.

Conclusion

Understanding the costs of owning a CO2 laser machine is key to making a wise investment. Take your time to evaluate your needs and budget carefully.

-

Explore detailed maintenance cost breakdowns for CO2 laser machines.: When it is dead, depending on manufacturer the tube can cost anywhere from 100$ onwards (in Chinese lasers, depending on Wattage of the tube) to … ↩

-

Compare maintenance costs of CO2 and fiber lasers for cost-effective decision-making.: Electrical consumption on a Fiber laser is lower by almost three times as compared to a CO2 laser of the same output power wattage, lowering … ↩

-

Discover ways to reduce energy consumption and lower costs.: Using cleaner energy sources, such as renewable energy, can also reduce the overall emissions associated with laser cutting. Regular maintenance … ↩

-

Explore how different elements affect upfront investment.: The brand of a laser cutting machine can significantly influence its price. Established brands, renowned for their reliability, durability, and … ↩

-

Discover how CO2 lasers enhance precision and versatility for businesses.: While on the topic of uniform colouration, CO2 laser resurfacing can also help improve the complexion by repairing sun damage or scarring, after … ↩