Have you ever wondered how intricate designs are perfectly etched into metal or wood? Laser engraving machines hold the key to this magic!

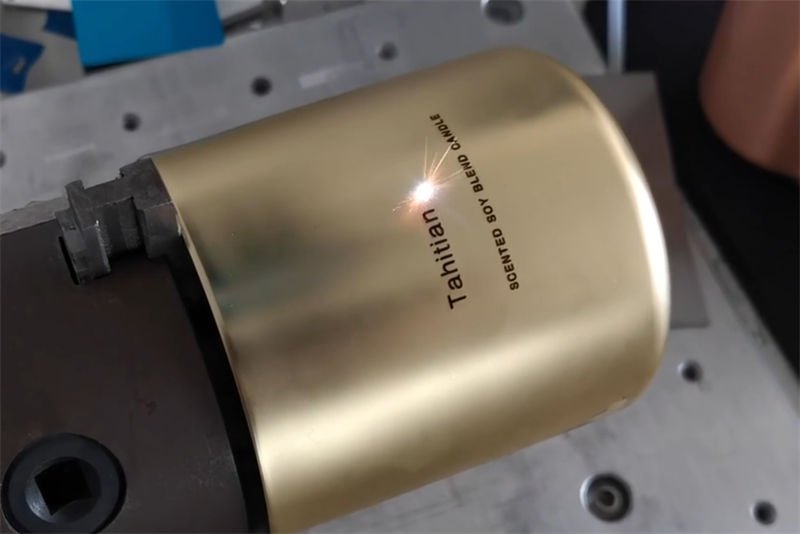

Laser engraving machines operate by directing a high-energy laser beam onto a material’s surface, causing physical or chemical changes that result in permanent markings. The process relies on components like the laser source, galvanometer system, and optical focusing to execute precise designs.

Understanding how these machines work can empower you to make informed decisions when purchasing one. Let’s delve deeper into the principles, components, and processes that define these remarkable devices.

Laser engraving uses a high-energy laser beam to mark surfaces.True

Laser engraving machines use focused laser beams to create permanent marks on materials.

What Are the Key Components of a Laser Engraving Machine?

Understanding the core components of a laser engraving machine is essential to harness its full potential.

A laser engraving machine comprises five key components: the laser source, galvanometer scanning system, control system, cooling system, and optical focusing system. Each plays a critical role in ensuring precise, efficient, and high-quality engraving.

Laser Source: The Heart of the Machine

The laser source is the engine that generates the high-energy laser beam necessary for engraving. Common types include fiber, CO2, UV, and solid-state lasers. Each type is tailored for specific materials; for instance, fiber lasers1 are ideal for metals, while CO2 lasers excel with non-metals like plastics and wood.

Galvanometer Scanning System: Precision in Motion

The galvanometer scanning system includes two rapidly moving mirrors that direct the laser beam across the material. By adjusting the mirrors’ angles, it ensures the laser swiftly and precisely follows the designed path, enabling intricate patterns or text.

Control System: The Brain Behind the Operation

This component consists of a computer and specialized software where users input designs and adjust engraving parameters such as laser power, scanning speed, and frequency. The control system orchestrates the operation, ensuring that the laser executes designs with pinpoint accuracy.

Cooling System: Managing Heat and Efficiency

Given the significant heat generated by the laser, a cooling system is essential to maintain stable operation and prolong the lifespan of the laser source. Common methods include air cooling for smaller systems and water cooling2 for more powerful machines requiring efficient heat dissipation.

Optical Focusing System: Concentrating Power

Equipped with a focusing lens, this system concentrates the laser beam to a fine point. This concentration increases the energy density at the surface, ensuring sufficient heat for precise engraving.

Table: Key Components Summary

| Component | Function |

|---|---|

| Laser Source | Generates the laser beam |

| Galvanometer System | Directs laser across material |

| Control System | Manages design input and operation parameters |

| Cooling System | Dissipates heat to ensure stability |

| Optical Focusing System | Concentrates laser for precision |

Understanding these components aids in optimizing machine performance and troubleshooting potential issues. As technology advances, these elements will continue to evolve, offering even greater precision and efficiency.

Fiber lasers are best for engraving non-metals.False

Fiber lasers are optimal for metals, not non-metals.

Cooling systems prolong laser source lifespan.True

Cooling systems manage heat, extending the laser's life.

How Does the Laser Engraving Process Differ from Laser Etching?

Laser engraving and etching are often confused, but they differ in depth and application. Understanding these differences is crucial for selecting the right method for your project.

Laser engraving involves removing material to create deep, permanent marks, while laser etching alters the surface to create shallow, less permanent designs. Both methods use lasers but differ in technique and material impact.

Understanding Laser Engraving

Laser engraving is a process that removes material from the surface to create deep and permanent marks. It is ideal for applications where durability and depth are critical, such as in industrial settings or for items exposed to harsh conditions. The laser beam’s intensity is controlled to vaporize or melt the material, resulting in a cavity that forms the design or text. This method is particularly effective on metals, ceramics, and certain plastics.

Key Characteristics of Laser Engraving:

- Depth: Engravings can range from micrometers to several millimeters deep, depending on the material and laser power.

- Material Removal: Involves physically removing material, often resulting in a noticeable indentation.

- Applications: Used for creating serial numbers, barcodes, and intricate designs that need to withstand wear and tear.

Exploring Laser Etching

Laser etching, on the other hand, is a subset of engraving where the laser alters the surface properties of the material without significant depth. It creates marks by causing a change in color or texture rather than removing material. This is achieved by melting a thin layer on the surface, which then cools and solidifies.

Key Characteristics of Laser Etching:

- Shallowness: Typically only alters the top layer of the material, making it less durable than engraving.

- Surface Alteration: Focuses on changing color or texture rather than depth, suitable for more delicate applications.

- Applications: Commonly used for branding logos or decorative designs on products where permanence is less of a concern.

Comparing Engraving and Etching

| Feature | Laser Engraving | Laser Etching |

|---|---|---|

| Depth | Deep, up to several millimeters | Shallow, only surface level |

| Material Impact | Removes material | Alters surface properties |

| Durability | Highly durable | Less durable |

| Common Materials | Metals, ceramics, plastics | Coated metals, glass, plastics |

| Typical Uses | Industrial parts, ID tags | Branding, decoration |

Laser engraving and etching serve distinct purposes. While laser engraving3 excels in creating long-lasting marks suitable for tough environments, laser etching offers flexibility for aesthetic applications where depth isn’t crucial. Depending on your project’s needs—whether it requires permanence or visual appeal—you can choose the appropriate method for optimal results.

Laser engraving removes material for deep marks.True

Engraving involves material removal to create permanent designs.

Laser etching is more durable than engraving.False

Etching alters surface properties, making it less durable.

What Factors Affect the Quality of Laser Engravings?

Laser engraving, a key player in precision marking, is influenced by several critical factors determining the final output quality.

The quality of laser engravings is affected by laser power, scanning speed, focus precision, and material characteristics. Proper calibration of these parameters ensures clear, precise, and durable markings. Inadequate settings may lead to subpar results, such as unclear or damaged engravings.

Understanding Laser Power

Laser power is a crucial factor in determining the depth and clarity of engravings. Higher power settings can achieve deeper cuts but risk causing over-ablation and material damage4. On the other hand, insufficient power might result in shallow or unclear markings, failing to achieve the desired outcome. Thus, finding the right balance is essential for optimal results.

The Role of Scanning Speed

The speed at which the laser moves across the material significantly impacts engraving quality. A high scanning speed might lead to incomplete markings due to reduced contact time between the laser and material. Conversely, a slower speed can cause excessive heating, potentially leading to material warping5 or damage. Adjusting the speed to match the material type and desired result is key.

Importance of Focus and Precision

Proper focus ensures that the laser beam is concentrated on a fine point, providing the necessary energy density for effective engraving. A misaligned focus can lead to blurry or off-target markings. Utilizing precise focusing techniques and equipment calibration helps achieve sharp and accurate engravings.

Material Characteristics

Different materials react uniquely to laser engraving due to their inherent properties like melting points, thermal conductivity, and reflectivity. For instance, metals generally require more power due to their high melting points and reflectivity, while plastics may need specific wavelengths to avoid burning. Understanding these material-specific traits6 enables the selection of appropriate laser settings for each task.

Practical Example: Metal vs. Plastic

| Factor | Metal | Plastic |

|---|---|---|

| Laser Power | High (due to high melting points) | Moderate (avoidance of melting) |

| Scanning Speed | Moderate (prevention of overheating) | Fast (prevention of burn marks) |

| Focus Precision | High (reflectivity considerations) | Moderate (ensuring surface penetration) |

By tailoring these factors—power, speed, focus, and material characteristics—to the specific requirements of each engraving project, one can significantly enhance the quality of laser engravings.

Higher laser power causes deeper engravings.True

Higher power increases energy, allowing the laser to cut deeper into materials.

Faster scanning speed improves engraving clarity.False

Faster speeds reduce contact time, often leading to incomplete or unclear markings.

Why Choose Laser Engraving Over Traditional Marking Methods?

In the realm of marking technologies, laser engraving stands out with its precision and versatility. But what makes it a superior choice over traditional methods?

Laser engraving offers unparalleled precision, permanence, and versatility compared to traditional marking methods. Its ability to work with diverse materials, minimal maintenance needs, and eco-friendly operation make it a preferred option across various industries.

Precision and Detail

Laser engraving allows for extremely fine details and intricate designs that traditional methods struggle to achieve. The high-energy laser beam7 is capable of marking even the smallest fonts or complex patterns with exact precision, which is crucial in sectors like jewelry or electronics.

Versatility Across Materials

One of the standout features of laser engraving is its adaptability to a wide range of materials. From metals and plastics to ceramics and glass, laser engravers can handle them all. Traditional methods often require specialized tools for different materials, while a single laser machine can be adjusted to suit various substrates by altering parameters like power and speed.

| Material Type | Traditional Methods Challenges | Laser Engraving Advantages |

|---|---|---|

| Metals | Requires multiple tools | Single setup, precise marks |

| Plastics | Risk of melting or warping | Non-contact, minimal heat impact |

| Glass | Brittle and hard to mark | Clean cuts with no cracking |

Durability and Permanence

The permanence of laser marks is another reason for its popularity. Laser-engraved marks are resistant to wear and tear, remaining legible even after exposure to harsh environments, unlike painted or printed marks that may fade over time. This durability is vital for industries like aerospace8, where component identification is critical.

Eco-Friendly Operation

Laser engraving is an eco-friendly process, producing minimal waste since it often requires no inks or solvents, unlike traditional printing methods. The precise nature of the laser also means less material wastage, aligning with sustainable practices increasingly demanded across industries.

Cost-Effectiveness Over Time

While the initial investment in a laser engraving machine can be higher than some traditional marking tools, the long-term savings are significant. Laser engravers typically have lower maintenance costs and longer lifespans, offering a better return on investment. Moreover, they reduce labor costs due to their high speed and automation capabilities.

Minimal Maintenance Needs

Compared to mechanical marking machines that require regular calibration and part replacements, laser engravers have fewer moving parts and hence lower maintenance demands. This reliability ensures consistent performance and minimizes downtime.

In conclusion, laser engraving not only matches but often surpasses traditional marking methods in efficiency, adaptability, and longevity. Its comprehensive benefits make it an ideal choice for businesses seeking reliable and high-quality marking solutions.

Laser engraving is more eco-friendly than traditional methods.True

Laser engraving produces minimal waste and requires no inks.

Traditional marking methods are more precise than laser engraving.False

Laser engraving offers unparalleled precision for intricate designs.

Conclusion

Laser engraving is not just about precision; it’s about unlocking creativity and innovation across industries.

-

Discover why fiber lasers are optimal for metal engraving.: While fiber lasers are ideal for metal engraving, CO2 lasers and diode lasers can also be used to create markings on metal. ↩

-

Learn how water cooling enhances machine performance.: Capable laser water chillers guarantee long-term, corrosion-free performance with consistent laser water cooling functionality to prolong the … ↩

-

Explore detailed distinctions between engraving and etching techniques.: Laser engraving involves vaporizing the material, allowing for deep marks on metal, wood, or plastic. On the other hand, laser etching makes the material … ↩

-

Understand how laser power influences material removal rates.: With the increase of laser power density, the ablation of the center region becomes severe, surface cracks occur, and more spherical SiC … ↩

-

Learn how scanning speed impacts material stability.: The higher the percentage of material removed, the more likely the balance of internal stresses are to be affected, causing warping. In general, … ↩

-

Discover ideal settings for different materials.: Bass Wood 80 60 40 Cut 50 65 80 15 NA NA 1/8 inch 1 Use lowest power with highest speeds to completely cut through the material. Higher speeds may be obtained … ↩

-

Discover how high-energy beams enhance engraving precision.: More powerful, higher-wattage lasers also can perform faster or deeper engraving, especially with acrylic, wood and other hard materials, according to Rabideau. ↩

-

Learn why durable markings are crucial in aerospace.: Durable and reliable marking solution. · Long-lasting. · The rugged solution that can bear the extremities of the operation. And provide great marking solutions … ↩