Choosing the right marking technology is crucial for success in today’s competitive landscape.

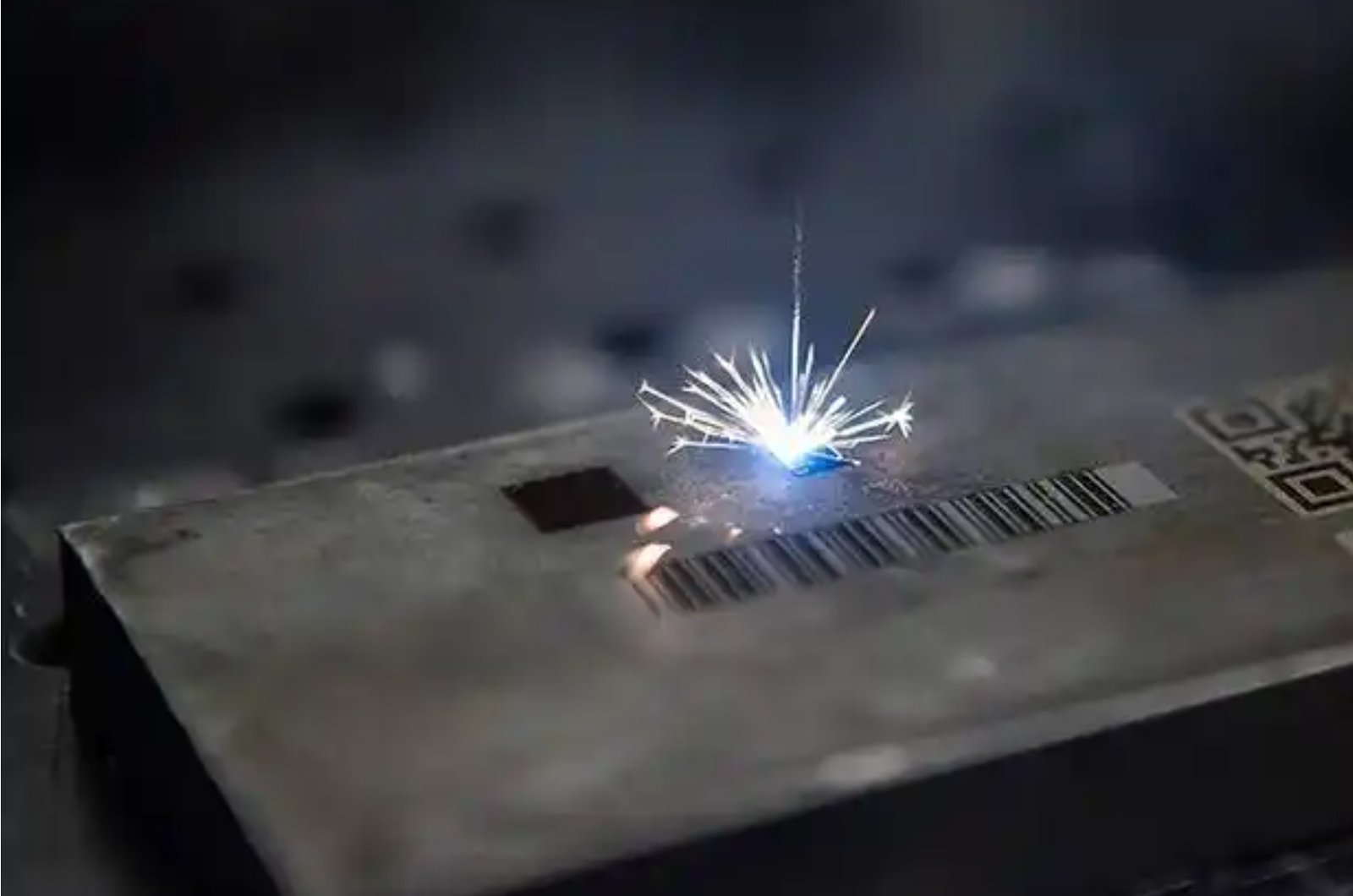

Fiber laser marking machines are renowned for their precision, versatility, and efficiency. They are ideal for marking metals, hard plastics, leather, and ceramics, providing high-speed and durable engravings suitable for various industries.

But there’s so much more to uncover! Let’s dive deeper into the unique capabilities of fiber laser marking machines and discover why they might be your next best investment.

Fiber lasers are more durable than gas lasers.True

Fiber lasers have fewer moving parts, enhancing durability.

How Does Fiber Laser Technology Work?

Fiber laser technology is a marvel of modern engineering, offering unparalleled precision and efficiency in marking applications.

Fiber lasers operate by directing a high-intensity beam through optical fibers, which are doped with rare earth elements. This setup amplifies light to create a powerful laser beam ideal for marking a variety of materials with speed and precision.

The Basics of Fiber Laser Operation

Fiber laser technology operates by channeling laser light through a flexible optical fiber. This fiber is doped with rare earth elements like erbium or ytterbium, which amplify the light as it travels through the fiber. The resulting beam is highly concentrated and coherent, making it ideal for precision applications.

In the core of this technology lies the "gain medium," where the light amplification occurs. When pumped with energy, typically from laser diodes, the atoms in the fiber’s core become excited. As these atoms return to their ground state, they emit photons, which then stimulate the emission of more photons—a process known as "stimulated emission." This is the fundamental principle behind all laser technologies.

Advantages of Fiber Optic Systems

Unlike traditional laser systems that rely on mirrors to direct the beam, fiber lasers use the fiber itself as a transmission medium. This results in several key advantages:

- Compact Design: Fiber lasers are inherently more compact due to the absence of bulky mirrors and other optical components.

- Efficiency: The light-amplifying process in optical fibers is highly efficient, converting more input energy into laser light.

- Durability: With fewer moving parts, fiber lasers offer superior durability and require less maintenance than their gas or crystal counterparts.

Application Areas and Material Compatibility

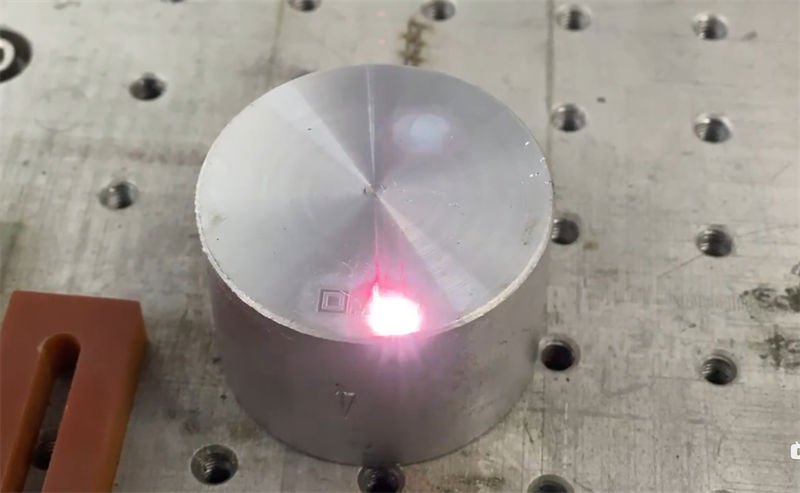

Fiber lasers excel in marking a variety of materials. They are particularly effective on metals such as steel and aluminum due to their ability to produce high-intensity beams that penetrate and alter surface properties. Additionally, fiber lasers can also be used on certain ceramics and plastics, expanding their versatility across different industries.

| Material | Suitability |

|---|---|

| Metals | High |

| Ceramics | Moderate |

| Plastics | Selective |

Understanding Beam Quality and Control

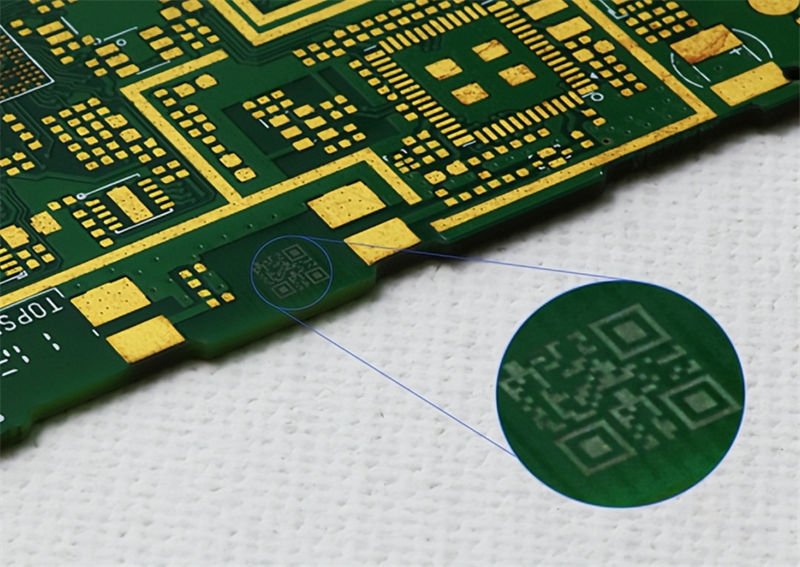

One of the standout features of fiber lasers is their beam quality. The single-mode beam profile allows for precise control over engraving depth and resolution. This precision is crucial for applications requiring intricate details, such as QR code marking on electronic components or decorative engravings on jewelry.

Furthermore, advancements in software enable users to manipulate beam characteristics such as power output and pulse frequency, allowing for customization based on material type and desired marking effect. These software enhancements1 are particularly beneficial for industries with diverse marking needs.

Overall, fiber laser technology’s integration of efficient design with precise control mechanisms positions it as a leading choice for industrial marking solutions.

Fiber lasers use mirrors to direct the laser beam.False

Fiber lasers use optical fibers, not mirrors, to direct beams.

Rare earth elements amplify light in fiber lasers.True

Elements like erbium or ytterbium amplify light in fibers.

What Industries Benefit Most from Fiber Laser Marking?

Fiber laser marking technology is transforming various industries with its precision and versatility.

Industries like electronics, automotive, and medical devices benefit most from fiber laser marking due to its ability to engrave metals and hard plastics efficiently, ensuring durability and clarity.

Electronics Industry

The electronics sector2 relies heavily on fiber laser marking for its ability to engrave detailed information on small components without damaging sensitive electronic parts. This precision ensures reliability in product identification and traceability, which is crucial for quality control and regulatory compliance.

- Applications: Serial numbers, barcodes, and logos on PCBs (Printed Circuit Boards), connectors, and semiconductors.

Automotive Industry

In the automotive industry, fiber laser marking is used extensively due to its capability to produce durable marks that withstand harsh environments. Whether marking engine components, VINs (Vehicle Identification Numbers), or other critical parts, the automotive sector benefits significantly from the permanence and clarity provided by fiber laser technology.

- Applications: Marking on metal and plastic parts such as gears, bearings, and dashboard components.

Medical Device Industry

The medical device industry requires precise and sterile marking solutions. Fiber laser marking offers a non-contact process that ensures cleanliness while providing high-quality engravings necessary for compliance with stringent regulatory standards.

- Applications: Surgical tools, implants, and medical equipment labeling.

Jewelry and Luxury Goods

In the luxury sector, fiber laser marking is ideal for engraving intricate designs on high-value items such as jewelry and watches. The ability to achieve fine detail without compromising material integrity is essential in this industry.

- Applications: Engraving on metals like gold and silver, as well as ceramics used in watches.

Aerospace Industry

Aerospace applications demand high precision and durability. Fiber laser markers fulfill these needs by providing long-lasting, legible marks on various materials used in aircraft manufacturing.

- Applications: Marking on engine parts, control panels, and structural components made of metals and composites.

The versatility of fiber laser marking machines makes them an indispensable tool across these industries, enabling businesses to meet both functional and regulatory requirements efficiently.

Fiber laser marking is crucial for electronics industry.True

It provides precise engraving on small components, ensuring reliability.

Fiber laser marking is not used in the medical device sector.False

It's used for sterile, precise engravings needed for regulatory compliance.

How Does Fiber Laser Compare to Other Marking Technologies?

Choosing the right marking technology can make or break your business’s branding efforts.

Fiber laser marking excels in precision, speed, and versatility compared to UV and nitrogen dioxide lasers. While ideal for metals and hard plastics, it’s limited on non-metals. Its efficiency and durability make it a preferred choice across many industries.

Understanding Different Marking Technologies

When considering marking technologies, it’s crucial to understand their applications and limitations. Fiber lasers3 are highly effective on metals and hard plastics, but what about other materials? Let’s compare fiber lasers with UV and nitrogen dioxide lasers.

| Technology | Ideal Applications | Limitations |

|---|---|---|

| Fiber Laser | Metals, hard plastics | Not suitable for most non-metals |

| UV Laser | Non-metals, some plastics | Limited depth on metals |

| Nitrogen Dioxide | Glass, ceramics | Slower process, less versatile |

Precision and Efficiency

Fiber lasers are renowned for their precision. The beam diameter is smaller compared to other laser types, allowing for intricate designs with excellent resolution. In contrast, UV lasers offer precision on non-metallic surfaces, while nitrogen dioxide lasers provide versatility on glass but often at slower speeds.

Speed of Operation

Speed is a critical factor in choosing a marking technology. Fiber lasers can operate at high speeds without sacrificing quality, making them suitable for large-scale production. UV and nitrogen dioxide lasers may require longer exposure times to achieve similar results on specific materials.

Cost-Effectiveness

Although initial costs for fiber laser systems might be higher, their longevity and minimal maintenance requirements make them cost-effective in the long run. In comparison, UV systems might involve more frequent maintenance due to their complexity.

Durability and Versatility

Fiber laser markings are highly durable, resisting wear over time, which is essential for industrial applications. While UV lasers offer versatility in marking various materials, they may not match the durability offered by fiber lasers.

In conclusion, understanding these differences can help you decide which laser technology aligns best with your business needs.

Fiber lasers are ideal for marking non-metal materials.False

Fiber lasers excel on metals and hard plastics, not non-metals.

UV lasers require longer exposure times than fiber lasers.True

UV lasers need more time to achieve similar results on some materials.

What Should You Consider Before Purchasing a Fiber Laser Marker?

Choosing the right fiber laser marker involves careful evaluation of several factors to suit your specific needs.

Before purchasing a fiber laser marker, consider its power output, material compatibility, software features, and support options. Evaluate the machine’s size, design, and optional accessories to ensure it meets your operational requirements and budget.

Understanding Power Output

When selecting a fiber laser marker, one of the primary factors to consider is the power output, typically ranging from 20W to 60W. Higher wattage offers deeper engravings or quicker processing times. For instance, a 50W fiber laser4 can efficiently handle metal engravings that require significant depth or speed.

Material Compatibility

Fiber laser markers are versatile but primarily excel at marking metals and some hard plastics. However, they have limitations with most non-metallic and transparent materials. Ensure the machine you choose can handle the materials you frequently work with, such as ceramics or leather, to avoid any operational constraints.

Software and Features

Advanced features like electric lifting for focusing and rotational capabilities enhance usability for larger or uniquely shaped items. Furthermore, ensure the laser marker includes robust software for both standard marking and specialized applications like 2.5D relief engraving. This flexibility can be pivotal in expanding your business capabilities.

Design and Portability

For businesses operating in limited spaces or those requiring mobility, a compact and lightweight design is essential. A custom-designed casing that is easy to transport can be beneficial for use in various settings, such as market stalls or during live demonstrations.

Support and Warranty

Evaluate the support system accompanying the purchase. A comprehensive support package might include remote learning, video tutorials, and an extensive library of templates. Moreover, a robust warranty covering several years can offer peace of mind regarding the durability and maintenance of the machine.

Accessories and Budget Considerations

Consider optional accessories like laptops or additional lenses that might enhance functionality. Weigh these against your budget to ensure you get the best value for your investment. Sometimes, investing in additional equipment upfront can save costs in the long run by expanding the machine’s capabilities.

By thoroughly evaluating these factors, you can make an informed decision about purchasing a fiber laser marker that aligns with your business needs.

Fiber lasers excel at marking metals.True

Fiber lasers are primarily designed for metal marking, offering precision.

All fiber lasers can engrave transparent materials.False

Fiber lasers struggle with non-metallic and transparent materials.

Conclusion

Fiber laser marking machines are a game-changer, offering unmatched precision and versatility for various industries. Evaluate their advantages to enhance your operational efficiency and product quality.

-

Learn about software features enhancing fiber laser customization.: Thanks to its powerful image processing functions, compatibility, and text processing, it meets all types of user demands. ↩

-

Explore why precision marking is crucial for electronics manufacturing.: Advantages and functions of laser technology · Permanent Marking Effect · Minimal maintenance · Non-Contact Process · Suitable for Different Materials and Process. ↩

-

Discover why fiber lasers are favored in diverse industrial sectors.: Fiber lasers are highly efficient and consume less power than conventional manufacturing machines. This reduces your carbon footprint and lowers your operating … ↩

-

Explore how a 50W laser enhances engraving depth and speed.: A 50 W, 75 W, and 100 W fiber laser are high-powered choices for metals that need deep engraving or cutting. These wattages are less precise and less … ↩