If you’ve ever marveled at the intricacies of modern metalwork, you’re not alone. I often find myself awestruck by the precision that laser cutting brings to the table. It’s not just about cutting metal; it’s about redefining what’s possible in fabrication.

Sheet metal laser cutting services offer superior precision, efficiency, and cost-effectiveness compared to traditional cutting methods. The technology allows for intricate designs, minimal waste, and faster production times, making it an ideal choice for complex and large-scale metal fabrication projects.

But there’s so much more beneath the surface. Understanding how laser cutting impacts material choices and project outcomes can help you unlock its full potential. Let’s dive deeper into this game-changing technology.

Laser cutting reduces material waste significantly.True

Laser cutting uses precise beams, minimizing excess material.

How Does Laser Cutting Improve Precision and Efficiency?

Laser cutting is a transformative technology in metal fabrication, enhancing both precision and efficiency significantly.

Laser cutting enhances precision and efficiency by using concentrated laser beams to achieve clean, accurate cuts with minimal waste and faster production cycles.

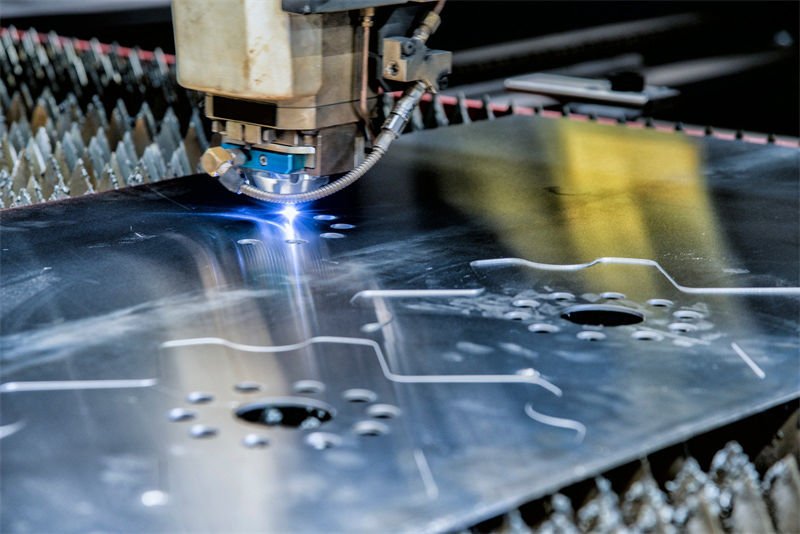

The Mechanics of Laser Cutting

Laser cutting operates by focusing a high-powered laser beam onto a material, melting or vaporizing it to create precise cuts. The laser’s precision allows for intricate designs and minimizes material waste. This process is controlled digitally, ensuring consistent results across multiple pieces.

Precision in Practice

The precision offered by laser cutting is unmatched due to its ability to handle complex geometries and fine details. For instance, creating components for electronics1 often requires tight tolerances and intricate designs. Laser cutting excels in these applications by producing high-quality edges and reducing the need for secondary finishing processes.

Efficiency Gains

The efficiency of laser cutting comes from its speed and automation capabilities. Unlike traditional methods that may involve manual intervention, laser cutters are typically integrated with computer-aided design (CAD) systems. This integration reduces setup times and allows for rapid prototyping, meeting the fast-paced demands of modern manufacturing environments.

Material Versatility

Laser cutting is suitable for a wide range of materials, including metals like stainless steel, aluminum, and copper. Each material interacts differently with the laser, but the versatility of the technology ensures optimal results regardless of the material properties. For example, stainless steel2 benefits from laser cutting due to its thickness and durability requirements.

| Material | Ideal Use Cases |

|---|---|

| Stainless Steel | Automotive parts, kitchen appliances |

| Aluminum | Aerospace components, lightweight structures |

| Copper | Electrical components, decorative pieces |

Environmental and Economic Impact

The precision of laser cutting not only leads to less material waste but also reduces energy consumption during the manufacturing process. Additionally, the speed and accuracy of laser cutting help lower production costs, making it a cost-effective solution for large-scale manufacturing projects.

Laser cutting produces high-quality edges.True

Laser cutting offers unmatched precision, creating clean, high-quality edges.

Manual intervention is often required in laser cutting.False

Laser cutting is automated and integrated with CAD systems, reducing manual tasks.

Why Is Laser Cutting More Cost-Effective Than Other Methods?

Laser cutting technology offers a unique combination of precision, speed, and flexibility that makes it a cost-effective solution for metal fabrication.

Laser cutting is more cost-effective than traditional methods due to its reduced material waste, faster production speed, and lower labor costs. It allows for precise cuts with minimal setup time, significantly reducing the overall production expenses, particularly for complex or high-volume projects.

Reduced Material Waste

One of the primary reasons laser cutting is cost-effective is its ability to minimize material waste. Traditional cutting methods often result in excess scrap due to less precise cuts and larger kerf widths. Laser cutting, however, uses a highly focused beam that allows for tight tolerances and intricate designs, ensuring minimal waste.

Consider the example of sheet metal fabrication3 for industrial components. Traditional methods might leave significant scrap material, whereas laser cutting optimizes each sheet’s usage, reducing costs associated with excess raw material.

Faster Production Speed

Laser cutting machines can operate at higher speeds compared to other cutting techniques, such as mechanical or waterjet cutting. This speed advantage translates directly into reduced production times, enabling manufacturers to meet tight deadlines and handle large orders efficiently.

For instance, automotive industry applications4 benefit from laser cutting by achieving faster turnaround times on parts production, which is crucial in high-demand scenarios.

Lower Labor Costs

Automation is another cost-saving aspect of laser cutting. Unlike traditional methods that require skilled labor to operate and monitor equipment constantly, laser cutting systems can be automated and integrated with computer numerical control (CNC) systems. This reduces the need for manual intervention, lowering labor costs substantially.

Automation allows businesses to allocate their workforce more efficiently, focusing on design and quality control rather than manual operations. This shift not only saves money but also enhances overall production quality.

Versatility in Material Processing

Laser cutting is not limited to just one type of material; it can be used effectively on a wide range of materials including metals like steel, aluminum, and even non-metals like plastics and wood. This versatility allows manufacturers to use one machine for multiple projects, further driving down costs associated with different types of cutting equipment.

For example, a fabrication shop5 that deals with various materials can consolidate operations with laser cutting technology, reducing the need for multiple specialized machines.

Minimal Tool Wear and Maintenance

Traditional cutting methods often incur high maintenance costs due to tool wear and tear. Laser cutting uses a non-contact process, meaning there’s minimal wear on the equipment itself. This translates to lower maintenance costs and longer machine lifespan.

In industries where precision is key, such as aerospace or electronics manufacturing, laser cutting offers a reliable solution with less downtime for repairs or tool changes.

In conclusion, while upfront costs for laser cutting technology can be high, the long-term savings on material waste, labor, and maintenance make it an attractive option for many businesses looking to optimize their manufacturing processes.

Laser cutting reduces material waste by 50%.False

Laser cutting minimizes waste but exact percentage varies by project.

Laser cutting equipment requires less maintenance than traditional.True

Non-contact process results in minimal wear, reducing maintenance costs.

What Materials Are Best Suited for Laser Cutting?

Laser cutting is renowned for its precision, but not all materials respond equally well to this technology. Choosing the right materials can significantly impact the quality of the final product.

Materials such as stainless steel, aluminum, and certain plastics are ideal for laser cutting due to their responsiveness to high precision cuts and minimal heat distortion. Each material offers unique benefits, making them suitable for various applications in metal fabrication.

Choosing Metals for Laser Cutting

When it comes to metals, laser cutting excels in processing materials with high precision and clean edges. Among the most popular choices are:

-

Stainless Steel: Known for its strength and corrosion resistance, stainless steel is perfect for applications requiring durability and aesthetic appeal. The ability to achieve intricate cuts without compromising structural integrity makes it a favorite in industries like automotive and aerospace.

-

Aluminum: Lightweight and highly conductive, aluminum is excellent for projects needing reduced weight without sacrificing strength. Its reflective nature requires specialized laser settings but yields excellent results in electronics and consumer goods.

-

Copper: While more challenging due to its reflective surface, copper’s excellent electrical conductivity makes it indispensable in electrical components. It requires specialized laser systems but offers unparalleled benefits in terms of thermal and electrical performance.

Considering Plastics for Laser Cutting

Plastics are another group of materials that respond well to laser cutting. They are favored for their versatility and ability to produce smooth edges:

-

Acrylic: This material is prized for its glass-like clarity and is widely used in signage and display products. Laser cutting acrylic provides clean edges and precise contours, perfect for intricate designs.

-

Polycarbonate: Although not as common as acrylic, polycarbonate offers superior impact resistance. It’s ideal for applications requiring durability alongside precision.

The Role of Material Properties in Laser Cutting

Understanding the material properties6 is crucial when selecting the best material for laser cutting. Factors like thermal conductivity, reflectivity, and thickness play significant roles in determining how a material will react under a laser beam.

For instance, metals with high reflectivity, such as aluminum and copper, require adjustments in laser power settings to prevent potential damage to the equipment. Meanwhile, materials with high thermal conductivity might demand slower cutting speeds to ensure clean cuts without excessive heat buildup.

By carefully analyzing these properties, you can select the optimal materials that align with your project requirements, ensuring both efficiency and quality in your laser cutting endeavors.

Stainless steel is ideal for laser cutting due to corrosion resistance.True

Stainless steel's corrosion resistance and strength make it ideal for precise laser cuts.

Copper is easy to laser cut due to its low reflectivity.False

Copper's high reflectivity makes it challenging for laser cutting, requiring special settings.

How Does Laser Cutting Enhance Product Quality and Design?

Laser cutting transforms how products are designed and built by enhancing precision, quality, and creative potential.

Laser cutting enhances product quality and design by offering precise cuts, allowing for intricate designs, reducing material waste, and maintaining the integrity of materials. This advanced technology is crucial for industries requiring high accuracy and aesthetic value.

Unmatched Precision for Superior Quality

Laser cutting provides unparalleled precision in cutting various materials, ensuring that each piece meets exact specifications. This precision is particularly important in industries such as electronics, aerospace, and automotive manufacturing, where even the smallest deviation can lead to significant issues. The laser beam’s ability to produce clean cuts with minimal kerf (the width of the cut) means less material waste and a higher quality end product.

Flexibility in Design

One of the most significant advantages of laser cutting is its flexibility. Designers can create complex patterns and intricate shapes that would be impossible or prohibitively expensive with traditional methods. This is particularly beneficial for creating unique architectural elements, custom-made furniture, or intricate jewelry designs. The technology allows designers to experiment with different shapes, textures, and patterns without compromising structural integrity.

Material Versatility

Laser cutting is compatible with a wide range of materials including metals, plastics, wood, and glass. This versatility allows manufacturers to select the best material for their design needs without being limited by the cutting process. For example, in electronics manufacturing, laser cutting can be used on stainless steel7 or aluminum sheets8, each offering distinct benefits in terms of conductivity and durability.

Enhancing Aesthetic Appeal

The clean and precise cuts achieved through laser technology enhance the aesthetic appeal of products. Smooth edges and precise detailing add to the visual quality of finished products. This is crucial in sectors like fashion or consumer electronics where appearance significantly impacts marketability.

Environmental Considerations

By optimizing material usage and reducing waste, laser cutting contributes to more sustainable manufacturing practices. The precision of laser cutting means fewer raw materials are needed to achieve the desired outcome, resulting in a smaller environmental footprint.

Applications in Prototyping

For prototyping, laser cutting enables rapid development cycles by allowing designers to quickly iterate on designs. This capability is crucial for product development teams looking to innovate and bring new products to market faster.

Laser cutting not only enhances the quality and precision of products but also opens up new possibilities in design and material selection. Its ability to reduce waste and improve sustainability makes it an attractive option across various industries.

Laser cutting reduces material waste significantly.True

Laser cutting's precision minimizes kerf, reducing material waste.

Laser cutting limits design flexibility in manufacturing.False

It enhances flexibility, allowing complex and intricate designs.

Conclusion

Embracing sheet metal laser cutting opens up a world of possibilities for precision and efficiency. Reflect on how these benefits align with your specific manufacturing goals.

-

Explore how laser cutting achieves intricate designs in electronics.: On the other hand, the dimensional accuracy is typically quite precise, at about ± 0.0005 inches. Why Is Laser Cutting Accurate? Since it is … ↩

-

Discover why stainless steel benefits from laser cutting techniques.: Laser cutting offers various advantages over more traditional approaches — it prevents work hardening, applies minimal heat to the metal, and … ↩

-

Discover how precise cuts reduce excess material costs.: We’ll cover five practical tips that can help optimize material utilization, improve efficiency, and minimize waste. ↩

-

Explore speed advantages in auto parts production.: The use of laser technology opens up many more possibilities such as interior and exterior applications in car production. ↩

-

Learn how one machine handles diverse materials efficiently.: For manufacturing shops and fabricators, investing in a laser machine is one way to diversify into new processes, clients or markets. ↩

-

Learn how material properties influence laser cutting effectiveness.: Materials such as POM, ABS, and polycarbonate stand out for their laser compatibility, offering a balance of cut quality, safety, and functional … ↩

-

Discover how stainless steel enhances durability and design flexibility.: All stainless steel alloys can be laser-cut given the proper machine settings, sufficient power, and the right controlled atmosphere. ↩

-

Explore why aluminum sheets are ideal for precise laser cutting.: The Benefits of Laser Cutting Aluminum · Precision Cutting · Less Expensive · Custom Jobs · Fast & Repeatable · Speed · Flexibility. ↩