Laser marking machines are widely used in modern manufacturing due to their efficiency and precision. Depending on application requirements and material types, three major types of laser marking machines dominate the market: Fiber Laser Marking Machines, CO2 Laser Marking Machines, and UV Laser Marking Machines. Each machine offers specific advantages and limitations, making them suitable for different industrial applications. This article provides an in-depth analysis of these three types and includes a comparison table to help you choose the best option for your needs.

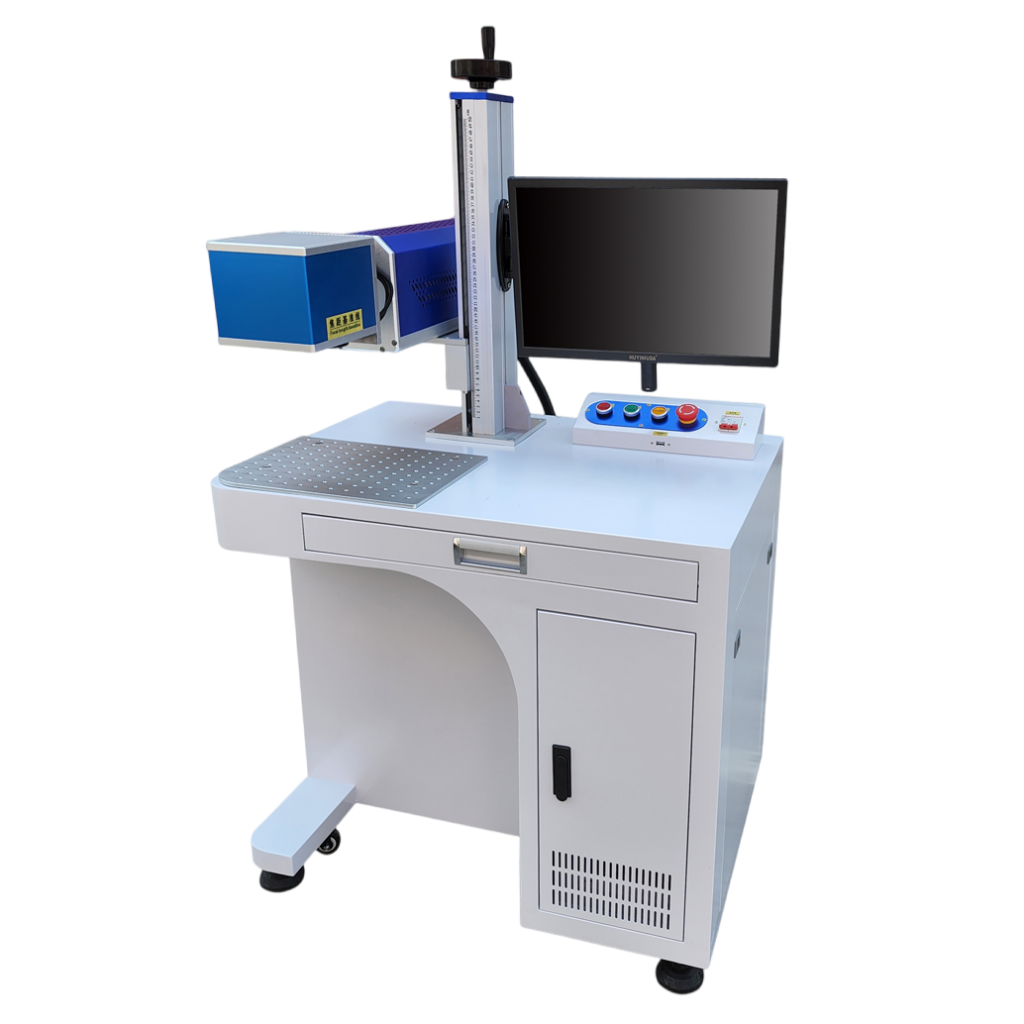

Fiber Laser Marking Machine

Fiber laser marking machines are among the most popular due to their versatility and efficiency. These machines use a fiber optic cable doped with rare earth elements to generate a laser beam, improving the machine’s stability, reliability, speed, and precision. Fiber lasers are widely used in industries that require high contrast and fine detail in their markings.

Applications

- Automotive Industry: Used to mark automotive parts such as engine components, chassis numbers, and instrument panels, ensuring durability and resistance to wear.

- Aerospace: Ideal for marking components like aircraft body parts and electronic devices, where high precision and traceability are essential.

- Electronics Industry: Suitable for marking characters, QR codes, and graphics on electronic components, providing permanent and high-contrast marks.

- Medical Industry: Used for marking medical tools and devices, ensuring clarity and corrosion resistance of the markings.

Advantages

- High Marking Speed: Fiber lasers significantly boost production efficiency, particularly in high-volume operations.

- Long Lifespan and Low Maintenance: Core components of fiber lasers last over 100,000 hours, requiring minimal maintenance and reducing long-term costs.

- High Precision and Contrast: Capable of fine markings with high resolution, making them ideal for applications requiring high detail and clarity.

Limitations

- Ineffective on Transparent Materials: Fiber lasers are less effective on materials like glass and certain plastics, as the laser beam passes through rather than marking the surface.

- Higher Initial Investment: Although fiber lasers have a higher upfront cost, their low maintenance and high efficiency make them a worthwhile investment in the long term.

CO2 Laser Marking Machine

CO2 laser marking machines are gas lasers that use a mixture of carbon dioxide, nitrogen, and helium to generate a laser beam. They are particularly suited for non-metallic materials, making them a popular choice in industries that work with wood, plastics, and textiles.

Applications

- Wood: Suitable for engraving and marking wooden products such as furniture, crafts, and packaging boxes, offering deep engraving and decorative marking.

- Leather: Ideal for marking and engraving high-precision designs on leather goods such as bags, shoes, and accessories.

- Paper and Cardboard: Commonly used for processing paper products like packaging, greeting cards, and stationery, providing clear marking results.

- Acrylic: Used for cutting and marking acrylic materials, often applied in sign-making, exhibitions, and advertising.

- Glass: Capable of marking on glass surfaces, including glassware, mirrors, and architectural decoration, providing detailed patterns and inscriptions.

- Plastics: Suitable for marking and cutting certain plastics like ABS and polycarbonate, commonly used in electronic enclosures, household items, and toys.

Advantages

- Deep Engraving Capability: CO2 lasers can engrave deeply into materials, creating marks with a 3D effect, particularly on wood, leather, and acrylic.

- Large Surface Marking: Capable of marking larger surface areas, making them practical for applications requiring extensive marking on larger materials.

- Lower Cost: CO2 lasers have a lower initial and operating cost compared to fiber lasers, especially when processing non-metallic materials, making them more accessible to small and medium-sized businesses.

Limitations

- Not Suitable for Metal Marking: CO2 lasers are generally ineffective for direct metal marking unless the surface is coated, which limits their use in certain applications.

- Slower Marking Speed: CO2 lasers have a slower marking speed compared to fiber lasers, which can affect production efficiency, especially in high-volume environments.

- Larger Footprint: The laser tube in CO2 lasers is larger, which requires more installation space, posing challenges in smaller production areas.

UV Laser Marking Machine

UV laser marking machines, also known as cold lasers, use a shorter wavelength to produce high-quality marks. This technology ensures minimal heat impact on the material, making UV lasers ideal for marking delicate, heat-sensitive materials.

Applications

- Plastics: Excellent for fine marking on various plastics, including polyethylene, polypropylene, and polycarbonate. UV lasers produce high-contrast marks that are easy to read on consumer goods, electronics, and appliances.

- Glass: Capable of creating stress-free, high-precision markings on optical lenses, laboratory glassware, and consumer electronics like smartphone screens.

- Ceramics: Commonly used in marking electronic components and decorative ceramics, such as capacitors and ceramic chips.

- Silicon Wafers and Sensitive Materials: UV lasers are ideal for processing silicon wafers in the electronics industry, offering minimal heat input to prevent damage to sensitive materials.

- Medical Devices: Used for marking surgical instruments, implants, and medical packaging, providing clear, durable, and contamination-free marks.

Advantages

- High Precision Marking: UV lasers can achieve micro-level precision, making them perfect for applications requiring detailed and complex markings, such as electronics.

- Minimal Heat Impact: The small heat-affected zone prevents material deformation, burning, or cracking, making UV lasers ideal for heat-sensitive materials like plastics and glass.

- Wide Material Compatibility: UV lasers can mark a wide variety of materials, including transparent and heat-sensitive materials, with high contrast and clarity.

Limitations

- Slower Marking Speed: UV lasers are slower compared to fiber lasers, which can impact overall production efficiency, particularly in mass production.

- Higher Cost: Due to the complexity of the technology, UV lasers have a higher initial investment and operating cost, making them a more expensive option for small businesses.

- More Frequent Maintenance and Shorter Lifespan: UV lasers require more regular maintenance and generally have a shorter lifespan than fiber lasers, which can increase long-term operational costs.

Conclusion

Choosing the right laser marking machine depends on your specific application needs and production requirements. Each type offers unique strengths:

- Fiber laser marking machines are ideal for metal marking and high-speed operations, providing a long-term cost-effective solution despite higher upfront costs.

- CO2 laser marking machines are perfect for marking non-metallic materials over large areas at a lower cost, making them an excellent choice for small and medium businesses.

- UV laser marking machines excel in high-precision and delicate applications, particularly with heat-sensitive materials, though they come with higher costs and slower marking speeds.

Understanding these differences will help you select the laser marking machine that best aligns with your production needs, improving both efficiency and product quality.

Laser Marking Machine Comparison Table

| Laser Marking Type | Equipment Cost | Marking Speed | Material Compatibility | Maintenance Cost |

|---|---|---|---|---|

| Fiber Laser | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★★☆ |

| CO2 Laser | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| UV Laser | ★★★★★ | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ |

Table Explanation:

- Equipment Cost: Represents the initial investment cost. The higher the stars, the more expensive the machine.

- Marking Speed: Reflects the speed of the machine’s marking process. The higher the stars, the faster the marking speed, making it more suitable for mass production.

- Material Compatibility: Indicates the range of materials the machine can mark. The higher the stars, the more versatile the machine.

- Maintenance Cost: Represents the long-term cost of maintaining the machine. The higher the stars, the higher the maintenance cost.

Summary

Although fiber laser marking machines have a higher initial cost, they are highly efficient in high-speed metal marking and come with low maintenance costs. CO2 laser marking machines are more cost-effective and ideal for processing large areas of non-metallic materials, while UV laser marking machines are designed for high-precision applications involving heat-sensitive materials. By considering your production needs and budget, you can choose the right laser marking machine to significantly enhance both productivity and product quality.