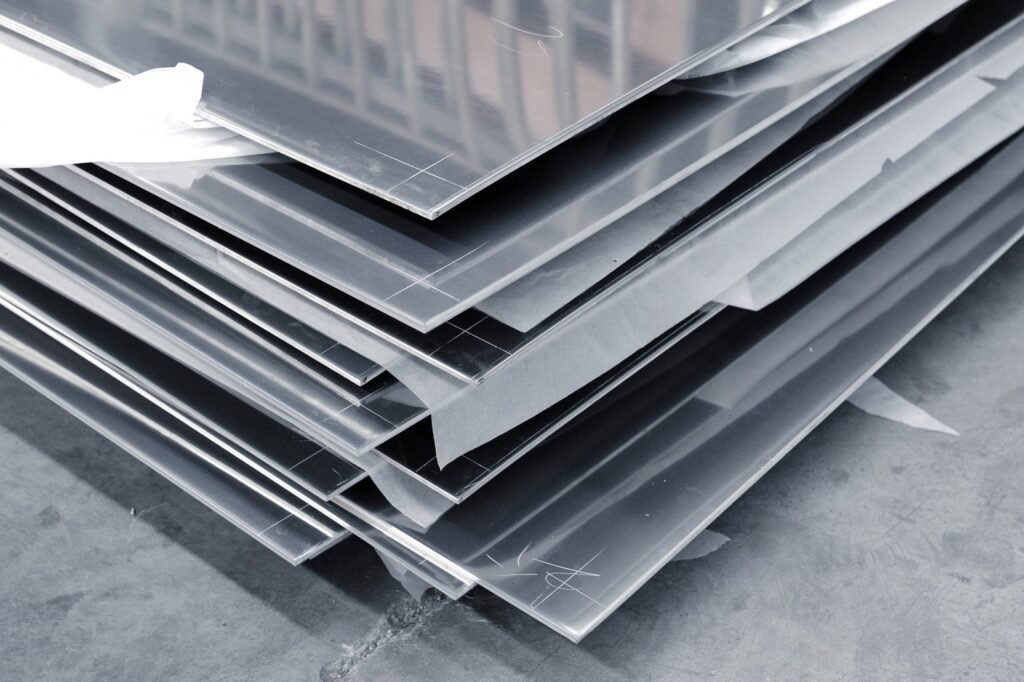

In the metal fabrication industry, cutting sheet metal is a crucial process that directly impacts the precision, efficiency, material utilization, and overall quality of the final product. Selecting the right cutting method is essential for achieving the desired results. Understanding the characteristics, advantages, disadvantages, and applications of various cutting techniques is vital for professionals in the metalworking industry. In this article, we will delve into common methods for cutting sheet metal, including laser cutting, plasma cutting, flame cutting, water jet cutting, and mechanical cutting, to help you make an informed decision.

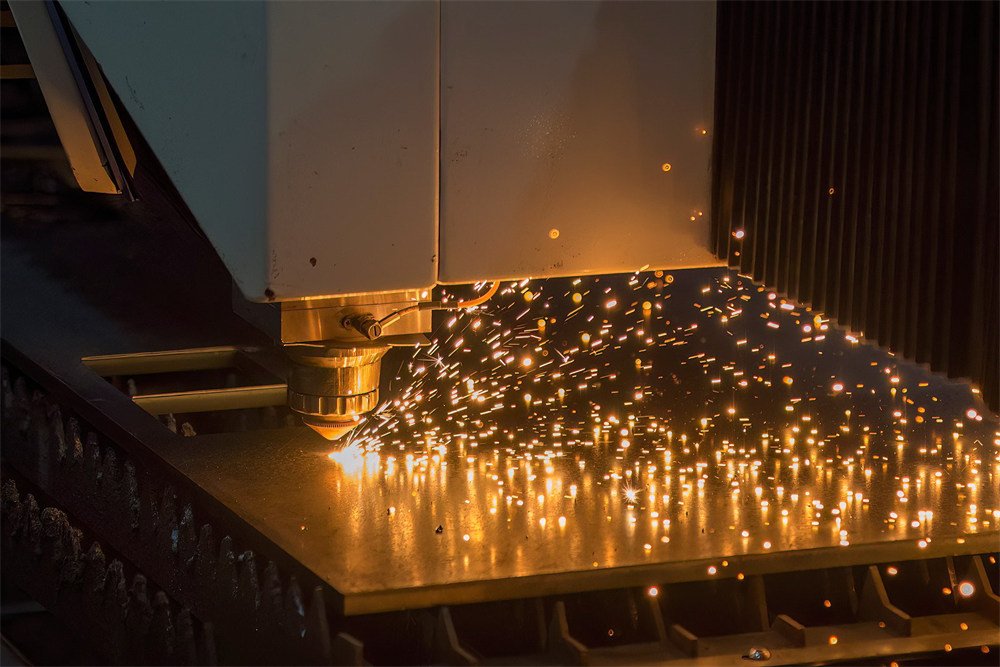

Laser Cutting

How It Works

Laser cutting is a technique that uses a high-energy laser beam to melt or vaporize metal, creating precise cuts. The laser beam, generated by a fiber or CO2 laser, is focused on the material’s surface through a series of lenses. Computer Numerical Control (CNC) systems allow for highly accurate cutting, making laser cutting ideal for intricate designs and shapes.

Advantages

- High Precision and Accuracy: Laser cutting is renowned for its exceptional precision, allowing for the cutting of complex and intricate patterns. This makes it highly sought after in applications requiring high accuracy, such as the manufacture of electronic components and precision instruments.

- Minimal Material Waste: The narrow kerf of laser cutting ensures that material waste is kept to a minimum, reducing the need for additional processing.

- Versatility: Laser cutting can handle a wide variety of materials, including steel, aluminum, brass, stainless steel, and even non-metals like plastics and wood.

- Efficient Processing: Laser cutting is not only fast but also capable of completing multiple complex cutting tasks in a single operation, significantly improving production efficiency.

Disadvantages

- High Initial Cost: Laser cutting machines are expensive to purchase and maintain, particularly high-power industrial lasers. This can be a challenge for small businesses.

- Requires Skilled Operators: Operating and maintaining laser cutting equipment requires specialized training to ensure efficient operation and high-quality cuts.

Plasma Cutting

How It Works

Plasma cutting uses a high-temperature plasma jet to melt metal and blow away the molten material, thereby cutting the metal. The plasma is created by an electric arc combined with a high-velocity gas stream, capable of reaching extremely high temperatures, making it ideal for cutting conductive metals.

Advantages

- Fast Cutting Speed: Plasma cutting is incredibly fast, especially when cutting thick metal sheets. It can easily penetrate steel plates several inches thick, significantly reducing production time.

- Effective for Thick Metals: Plasma cutting is particularly effective for thick metals and conductive materials such as aluminum, copper, and steel, providing good cutting results at high production speeds.

- Lower Equipment Cost: Compared to laser cutting, plasma cutting equipment is more affordable, making it an economical choice for small and medium-sized businesses.

Disadvantages

- Lower Precision: While plasma cutting is fast, it lacks the precision of laser cutting, making it less suitable for tasks that require fine detail, such as those involving intricate designs.

- Additional Cleanup Required: The process can produce a significant amount of dross and slag, necessitating additional cleanup and post-processing, which can increase time and costs.

Flame Cutting (Oxy-Fuel Cutting)

How It Works

Flame cutting, also known as oxy-fuel cutting, is a traditional metal cutting method that uses a torch to burn a mixture of oxygen and fuel gas (such as acetylene or propane) to generate high heat. The metal is heated to its ignition temperature, and then an oxygen jet is used to oxidize and blow away the molten metal, creating a cut.

Advantages

- Ideal for Thick Steel Plates: Flame cutting is particularly effective for cutting thick carbon steel, with thicknesses reaching several inches or more. This makes it widely used in heavy industry and construction.

- Low Operating Costs: The initial investment and operating costs for flame cutting equipment are relatively low, especially for cutting large, heavy materials.

- Easy to Maintain: Flame cutting equipment is simple in structure, easy to maintain, and suitable for use in harsh environments.

Disadvantages

- Limited Material Application: Flame cutting is mainly used for cutting carbon steel and is less efficient or ineffective for other materials, such as stainless steel and aluminum.

- Large Heat-Affected Zone: The high heat generated by flame cutting can cause material distortion or warping, especially when cutting thinner materials.

- Lower Precision: Flame cutting is less precise than laser and plasma cutting, often requiring further processing to achieve the desired precision.

Water Jet Cutting

How It Works

Water jet cutting uses a high-pressure stream of water mixed with abrasive materials to cut through a wide variety of materials. This process relies entirely on the mechanical action of the water, generating no heat and thereby preventing any thermal distortion.

Advantages

- No Heat-Affected Zone: Since water jet cutting generates no heat, the material does not experience thermal distortion or warping, making it ideal for cutting heat-sensitive materials.

- Versatility: Water jet cutting can handle almost all materials, whether soft or hard, from metals to stone to glass, making it a highly versatile cutting method.

- Environmentally Friendly: The process does not produce harmful gases or dust, and both the abrasive and water can be recycled, making it an environmentally friendly option.

Disadvantages

- Slower Cutting Speed: Water jet cutting is generally slower than plasma and laser cutting, making it less suitable for high-output applications where speed is critical.

- Higher Operating Costs: The abrasives used in water jet cutting require regular replacement, and the maintenance of high-pressure pumps can be expensive, increasing overall operational costs.

Mechanical Cutting (Shearing, Sawing, Punching)

Shearing

Shearing is a quick method for making straight cuts on sheet metal by applying a sharp blade to the material. It’s efficient for simple cuts but limited to straight lines.

Sawing

Sawing involves using a saw blade to cut through metal. It’s suitable for thicker materials but is slower and less precise than other methods.

Punching

Punching uses a punch press to create holes or cut specific shapes in the metal. It is fast and economical for repetitive patterns but limited to predefined shapes.

Advantages

- Cost-Effective: Mechanical cutting methods generally have lower setup and operating costs, especially for high-volume production.

- Simple to Operate: These methods require less technical expertise compared to laser or plasma cutting, making them easier to operate and maintain.

- Quick for Straightforward Tasks: Ideal for high-volume, repetitive tasks involving simple cuts, mechanical cutting methods provide efficient solutions for basic operations.

Disadvantages

- Lower Precision: Mechanical cutting methods are less precise than laser or water jet cutting, making them less suitable for intricate designs or detailed work.

- Higher Material Waste: These methods often produce more waste due to wider kerf and less control over the cut, leading to lower material utilization.

Comparison of Methods

Precision and Accuracy

Laser cutting offers the highest precision, ideal for detailed work with strict accuracy requirements. Water jet cutting avoids thermal distortion, suitable for cutting heat-sensitive materials and complex shapes. Plasma cutting is less precise than laser but offers high-speed cutting for thick metals. Flame cutting provides lower precision, mainly used for rough cutting of thick carbon steel. Mechanical cutting is suitable for simple straight cuts but lacks the precision of other methods.

Speed and Efficiency

Plasma cutting is the fastest for cutting thick materials. Laser cutting is efficient for both thin and thick materials with high precision. Flame cutting is fast but can cause significant heat distortion. Water jet cutting is slower but precise, suitable for a wide range of materials. Mechanical cutting has moderate speed, best for large-scale, simple cutting tasks.

Cost Considerations

Flame cutting offers the lowest initial and operating costs, ideal for cutting large, heavy materials. Mechanical cutting has lower equipment and operational costs, suitable for high-volume production. Plasma cutting is more affordable than laser cutting, with moderate operational costs. Laser cutting has a high initial cost, but its precision and efficiency can offset some expenses. Water jet cutting has the highest initial and operational costs, best for specialized cutting tasks with strict requirements.

Material Suitability

Laser cutting is versatile, capable of cutting a wide range of materials including metals, plastics, and wood. Water jet cutting is applicable to almost any material, especially where heat distortion is a concern. Plasma cutting is best for conductive metals like steel and aluminum. Flame cutting is ideal for thick carbon steel. Mechanical cutting is suitable for basic metal cutting, such as steel and aluminum.

Best Method for Specific Applications

For prototyping and small batch production, laser cutting is the best choice for high-precision tasks. It offers the ability to quickly and accurately cut complex designs and shapes. Plasma cutting and mechanical cutting excel in high-volume production, especially when speed and cost efficiency are primary considerations. Plasma cutting is ideal for quickly processing thick materials, while mechanical cutting is advantageous for simple, repetitive tasks. For cutting thick steel and heavy-duty metal, flame cutting is recommended. Water jet cutting is the ideal choice for cutting heat-sensitive or specialized materials, avoiding thermal distortion and capable of cutting a wide range of materials, including metal, glass, and ceramics.

Choosing the best method for cutting sheet metal depends on various factors, including the type of material, thickness, precision requirements, cost, and production efficiency. Laser cutting is the top choice for applications requiring high precision, while flame and plasma cutting offer speed and cost advantages for thicker materials. Water jet cutting is preferred for cutting specialty materials or tasks requiring high precision without heat distortion, while mechanical cutting is suitable for simple, cost-effective tasks. Understanding the advantages and limitations of each cutting method will help you select the most suitable technology for your specific needs, optimizing your production process and enhancing product quality.

If you have any questions about choosing the right cutting method or would like to learn more about Royell’s laser cutting solutions, please feel free to contact us. Our team of experts is here to provide professional advice and help you find the best cutting method for your specific application needs.