Hey there! Ever wondered what makes a laser engraving machine truly exceptional?

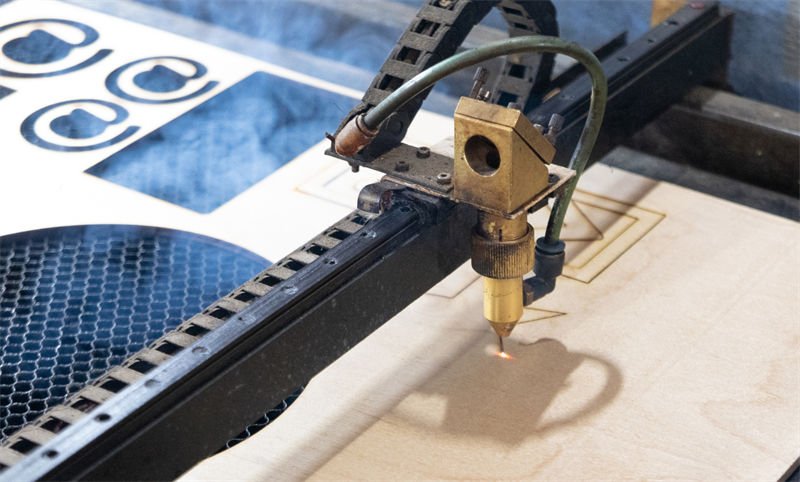

The 6090 CNC CO2 Laser Engraving Machine is a standout due to its remarkable precision, versatility across various materials, and intuitive design. It’s renowned for its durability and reliable performance in both cutting and engraving, making it a preferred choice for many.

Imagine being able to smoothly transition from engraving delicate glass pieces to cutting through thick acrylic sheets—all with one machine. That’s exactly what drew me to the 6090 model. It’s not just about its specs; it’s the consistent quality that allows me to focus on creativity rather than constant adjustments. When I first started using it, I was amazed at how it handled different projects with such ease and precision. It’s this kind of reliability that keeps my workflow efficient and my clients satisfied. So, let’s dive deeper into why this machine might just be your next best investment.

The 6090 CNC CO2 is only suitable for metal engraving.False

The machine is adaptable to various materials, not just metal.

The 6090 CNC CO2 offers high precision in engraving tasks.True

It is noted for its high precision and consistent performance.

How does the 6090 CNC CO2 Laser Engraving Machine compare to other models?

Ever wondered if the 6090 CNC CO2 Laser Engraving Machine is truly the MVP in its class? Let’s take a closer look and see what makes this machine a standout choice.

The 6090 CNC CO2 Laser Engraving Machine stands out for its precision, affordability, and versatility. With its expansive working area and powerful laser, it’s perfect for businesses prioritizing quality and efficiency, making it a top contender against other models.

Key Features of the 6090 CNC CO2 Laser Engraving Machine

I still remember the first time I laid eyes on the 6090 model—it was like meeting an old friend who somehow always had the right tools for every job. With a working area of 600mm x 900mm, it’s like having an extra set of hands that never complain about the workload. This space is perfect for those of us who need the freedom to work with different material sizes without constantly shifting everything around. Plus, the CO2 laser tech ensures every cut and engraving is as precise as if I’d done it by hand with a steady heartbeat.

Performance Comparison

In the world of laser engraving, comparing performance1 is like choosing between different types of coffee beans. You need to know what you’re getting into. The 6090 model ranges from 60W to 150W in laser power, which is like having an espresso machine that can brew a single shot or fill an entire carafe. This range surpasses many other models, ensuring detailed engravings and smooth cuts every time.

| Model | Working Area (mm) | Laser Power (W) | Material Compatibility |

|---|---|---|---|

| 6090 | 600 x 900 | 60-150 | Wood, Acrylic, Leather |

| Other Model A | 400 x 600 | 40-100 | Limited |

| Other Model B | 500 x 700 | 50-120 | Moderate |

Cost-Effectiveness

Cost is always a concern—I get it. When I first started my business, every penny counted. That’s why the cost-effectiveness2 of the 6090 model caught my attention. It’s priced competitively, and with its robust features, it feels like getting a luxury sedan for the price of a compact car. Many businesses find that any initial investment pays off quickly with the machine’s efficiency and high-quality output.

Versatility and Material Compatibility

One thing I love about the 6090 is its versatility—like having a Swiss army knife in my workshop. Whether I’m working on wood, acrylic, or leather, this machine handles it all with grace. It opens up endless possibilities for creating intricate designs or clean cuts. For industries like signage or personalized gifts, it’s like finding that perfect recipe that keeps customers coming back for more.

When considering other machines, it’s essential to weigh their specialized features against the broad material compatibility3 of the 6090.

User Experience and Maintenance

Operating the 6090 is a breeze; it’s as user-friendly as a smartphone app—simple enough even for newcomers to master quickly. And with minimal maintenance requirements due to its solid construction, I can spend more time crafting and less time fixing.

Conclusion: What to Consider

While the 6090 CNC CO2 Laser Engraving Machine is impressive, it’s important to reflect on your specific needs before diving in. Consider what projects you have in mind, which materials you’ll use most frequently, and how it fits into your budget. This way, you can decide if this model truly aligns with your business goals or if another might better serve your unique needs.

The 6090 model has a larger working area than Model A.True

The 6090 model's working area is 600x900mm, larger than Model A's 400x600mm.

Model B offers higher laser power than the 6090 model.False

Model B's laser power ranges from 50-120W, less than the 6090's 60-150W.

What Materials Can You Work With Using the 6090 CNC CO2 Laser?

Unlock the potential of the 6090 CNC CO2 laser to transform everyday materials into extraordinary creations. Dive into a world where wood, acrylic, and even glass become your canvas.

The 6090 CNC CO2 laser is a versatile tool that can process materials like wood, acrylic, leather, glass, and some metals, making it suitable for both artistic and industrial applications.

Exploring Material Options

Let’s take a journey through the world of materials you can explore with the 6090 CNC CO2 laser. I remember the first time I watched in awe as this machine transformed a plain piece of wood into a work of art.

Wood

Wood is like the bread and butter of laser cutting4. With the 6090 CNC CO2 laser, you can etch intricate designs on plywood or MDF with ease. I once made a wooden clock with detailed carvings that became a centerpiece in my home.

Acrylic

Acrylic is an artist’s dream. The laser slices through it like butter, leaving a polished edge that’s perfect for vibrant signage or eye-catching decorative pieces. I remember creating a custom nameplate for my niece; she loved the way it caught the light.

Leather

Leather offers a unique canvas for fashion enthusiasts. Whether it’s crafting personalized wallets or belts, the laser ensures precision without damaging the material. I tried engraving my initials on a leather bookmark once, and it was a hit among my book club friends.

Glass

Etching on glass can be challenging but rewarding. The 6090 can etch delicate patterns onto surfaces like wine glasses—perfect for gifts! I etched a set of glasses for a friend’s wedding; they were thrilled with the personal touch.

| Material | Ideal Use Cases | Thickness Range |

|---|---|---|

| Wood | Furniture, Artworks | Up to 20 mm |

| Acrylic | Signage, Displays | 1 mm – 10 mm |

| Leather | Fashion Accessories | Varies |

| Glass | Decor, Personalized Gifts | Surface Engraving |

Metals

While not its primary forte, the 6090 can engrave metals like anodized aluminum. This is perfect for branding or creating serial numbers. I remember helping a friend mark his tools with his logo—it’s all about making things truly yours.

Tips for Optimizing Material Use

Mastering the art of laser cutting means knowing your materials inside out. Testing different settings is crucial to get that perfect cut or engrave. Remember when I first tried acrylic? It took a few tries to get it right but learning from mistakes is part of the fun!

For detailed instructions on settings for specific materials, check out laser cutting guidelines5. Tweak those power and speed settings to avoid waste and boost efficiency—it’s like finding the perfect rhythm.

Safety Considerations

Safety always comes first. Ensure good ventilation and wear appropriate protective gear to keep things safe while you unleash your creativity. It’s like wearing an apron before baking—a small step that makes all the difference. For more safety tips, refer to laser safety measures6.

The 6090 CNC CO2 laser can cut metal sheets.False

CO2 lasers are not typically used for cutting metals; they engrave them.

Leather can be engraved with the 6090 CNC CO2 laser.True

The laser engraves leather smoothly, allowing for product customization.

How Long Does a 6090 CNC CO2 Laser Engraver Typically Last?

I remember when I first got my hands on a 6090 CNC CO2 laser engraver; I was both excited and nervous about its longevity.

A 6090 CNC CO2 laser engraver generally lasts between 5 to 10 years. Its lifespan depends heavily on regular maintenance, optimal operating conditions, and the quality of its components.

Factors Affecting Longevity

-

Maintenance Routine

I can’t stress enough how crucial regular maintenance is. Imagine it like taking care of a classic car—every detail counts. Cleaning optical lenses and checking laser tube alignment might seem like minor tasks, but they make a huge difference. Just like how I’d ensure my old car runs smoothly by giving it regular check-ups.

Maintenance Task Frequency Clean Optical Lenses Weekly Check Laser Alignment Monthly Ventilation Check Bi-Monthly -

Usage Frequency

It’s like owning a treadmill. If it’s used daily at high speeds, it wears out faster than one that’s only used occasionally. Similarly, if your engraver runs continuously in a bustling workshop, you’ll need to replace parts more frequently than if it’s a hobby tool in a cozy corner of your garage.

-

Environmental Conditions

I once stored my machine in a damp basement, and let’s just say I learned my lesson quickly. Dusty or humid environments can seriously cut down your machine’s lifespan. Keeping your workspace clean and dry is like giving your engraver a long, healthy life.

-

Component Quality

My first engraver came with bargain-basement parts, and it didn’t last long. Investing in high-quality parts is like buying premium tires for your car—they might cost more upfront, but the durability pays off in the long run.

-

Technological Updates

Think of it as upgrading your smartphone software to keep it running smoothly. Regular updates ensure your machine stays efficient and compatible with the latest design technologies7.

Comparing Brand Durability

Brands differ significantly, and it pays to do your homework. I remember spending countless evenings comparing brands, reading reviews like they were bedtime stories.

| Brand | Average Lifespan | Customer Rating |

|---|---|---|

| Brand A | 6-8 years | 4.5/5 |

| Brand B | 7-10 years | 4.7/5 |

| Brand C | 5-7 years | 4.3/5 |

Understanding these factors helped me make a confident decision about my laser engraver investment. Whether you’re purchasing new or maintaining an existing machine, these insights could guide you just as they have guided me.

Regular maintenance extends laser engraver lifespan by 2 years.True

Proper care, like cleaning lenses and checking alignment, increases longevity.

All brands of 6090 CNC CO2 laser engravers last over 10 years.False

Brand lifespans vary; most last between 5-10 years as per data.

How Can You Improve Your Engraving Quality with the 6090 Machine?

Ever felt like your engraving projects could use a little magic touch to shine brighter? You’re not alone. Let’s dive into some tried-and-true methods to make your 6090 machine engravings pop with precision and flair.

To achieve top-notch engraving quality with a 6090 machine, adjust the DPI settings, choose the right materials, keep lenses clean, and regularly calibrate your machine. These steps ensure your engravings are crisp and clear.

Fine-Tuning DPI and Laser Speed

When I first started experimenting with the 6090 machine, I felt like a kid with a new toy—but quickly realized it was more like a sophisticated puzzle. One crucial piece? DPI settings. Think of DPI as the number of tiny dots that come together to form an image. A higher DPI can reveal intricate details, but it’s a bit like adding more pieces to a puzzle: it takes more time and patience. I found starting at 300 DPI was a sweet spot, then tweaked from there depending on the material8. And don’t forget about laser speed! Slower speeds can enhance detail but require vigilance to avoid overheating—I’ve had my fair share of singed projects!

Material Choice and Preparation

Selecting the right materials can feel like picking the perfect fabric for a dress you’re sewing. Every type reacts differently to the laser, and preparation is key. For wood, a quick sanding can work wonders, while acrylics love a good clean-up before they meet the laser. Metals are a bit more straightforward but don’t let that fool you into skipping prep.

Refer to this simple table for guidance:

| Material | Suggested DPI | Pre-Treatment |

|---|---|---|

| Wood | 300-600 | Sanding |

| Acrylic | 400-500 | Cleaning |

| Metal | 100-200 | None |

Regular Maintenance

Maintenance is like brushing your teeth—it’s not glamorous, but essential! I remember neglecting this once, only to watch my engravings lose their crispness. Regular cleaning of lenses and mirrors keeps the laser’s path clear and precise, ensuring each project is as sharp as possible. A routine calibration also helps maintain that much-needed alignment. Check out this maintenance checklist9 I use to stay on track.

Experiment with Line Intervals and Focus

Playing with line intervals can be surprisingly satisfying. Smaller intervals can produce finer details but take longer—kind of like cooking on a low flame for richer flavors. Adjusting the laser focus can also bring out depth and clarity in your work, almost like adjusting the lens on a camera for that perfect shot. I usually grab some scrap material and run tests to find the optimal focus setting10 for each project.

Enhancing your engraving quality is all about blending technical skills with creativity. Keep experimenting, keep learning, and watch as your projects transform into masterpieces that reflect your dedication and skill.

Higher DPI always improves engraving quality.False

Higher DPI can enhance detail but may increase processing time.

Regular maintenance is essential for optimal performance.True

Cleaning lenses and calibrating ensure precision and clarity.

Conclusion

The 6090 CNC CO2 Laser Engraving Machine excels in precision, versatility, and user-friendliness, making it ideal for various materials and projects while ensuring cost-effectiveness and durability.

-

Explore comprehensive performance reviews and comparisons with other models. ↩

-

Learn about the financial benefits and return on investment of the 6090 model. ↩

-

Discover which materials are best suited for different laser machines. ↩

-

Explore various wood types compatible with laser cutting to enhance your projects. ↩

-

Find detailed guides on setting adjustments for different materials. ↩

-

Learn essential safety measures for operating a laser machine. ↩

-

Explore current software options to enhance design capabilities and ensure compatibility with your CNC CO2 laser engraver. ↩

-

Learn how different materials require specific laser settings to optimize engraving quality. ↩

-

Explore a comprehensive checklist to maintain your laser engraving machine in top condition. ↩

-

Discover techniques for adjusting the laser focus to improve engraving detail and clarity. ↩