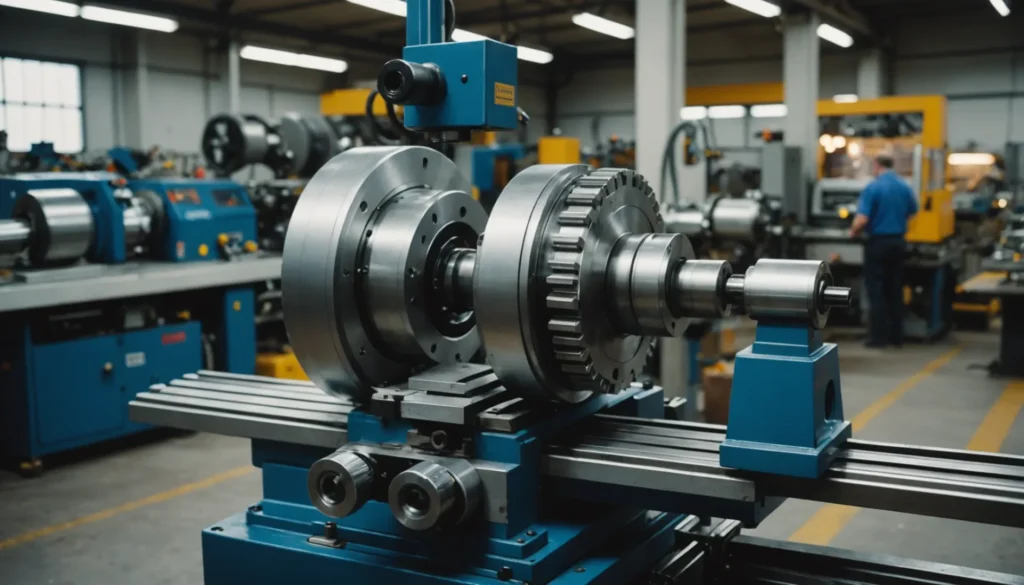

What Should You Consider When Choosing a Custom CNC Turning Lathe?

Selecting the right custom CNC turning lathe involves evaluating several critical factors. Key considerations include the size and complexity of parts to be machined, required precision levels for different industries, material characteristics that affect tool wear and machining efficiency, as well as performance parameters like spindle speed and torque. Additionally, understanding the costs associated with purchase and operation is essential for budget management. Automation features can enhance productivity by reducing manual intervention. Ultimately, aligning these factors with your specific operational needs will ensure optimal performance and long-term satisfaction with your CNC lathe investment.

What Are the Best Applications for CNC Machines?

CNC machines have transformed manufacturing by enabling high precision and automation across multiple industries. In aerospace, they create critical aircraft parts; in automotive, they ensure engine component accuracy. Electronics benefit from CNC’s ability to produce intricate circuit boards and heat sinks. Mold manufacturing relies on CNC for crafting detailed molds essential for plastic products. Additionally, the medical field utilizes CNC technology to manufacture surgical instruments and implants with exceptional precision. This article explores how different sectors leverage CNC machines to optimize production processes while maintaining stringent quality standards.

Is Investing in a CNC Machine Worth It for Your Business?

Investing in a CNC machine can significantly boost your business’s production efficiency, product quality, and market competitiveness. While the initial financial outlay is substantial, the long-term benefits often outweigh these costs. CNC machines automate machining processes, reduce manual errors, and allow for continuous operation, which enhances productivity. They also offer flexibility to adapt to changing production requirements quickly. However, businesses must evaluate their specific needs, budget constraints, and potential return on investment before making such a significant purchase. Understanding both the upfront costs—including equipment purchase and installation—and ongoing operational expenses is crucial for ensuring that this investment aligns with long-term growth strategies.

What Are the Best Alternatives to CNC Milling Machines?

This blog post discusses the best alternatives to CNC milling machines, highlighting traditional manual and semi-automatic milling options, as well as advanced technologies like 3D printing (FDM and SLA) and laser cutting. Each method is explored in terms of its advantages for different tasks such as small batch production, prototyping, and intricate designs. The article emphasizes the importance of selecting the right tool based on project complexity, precision requirements, and budget constraints. Whether you’re a hobbyist or a professional seeking efficiency in manufacturing processes, understanding these alternatives can help you make informed decisions that align with your specific needs.

What Are the Key Advantages of Using a Milling Machine?

Milling machines are indispensable tools in modern manufacturing. They offer unparalleled precision and versatility, enabling engineers to create complex parts with exceptional accuracy. This article explores the key advantages of milling machines, including their efficiency, material compatibility, and cost-effectiveness, providing insights into how they can transform your manufacturing processes.

Glass vs. Metal CO2 Laser Tubes: Which is Better?

Choosing between glass and metal CO2 laser tubes involves understanding their differences in cost, durability, performance, and maintenance. Glass tubes are cheaper but fragile; metal tubes are more durable and efficient. This guide explores the pros and cons of each type to assist in making an informed decision based on specific needs and budget considerations. Whether for light tasks or heavy industrial use, knowing the right tube can enhance operational capabilities while balancing upfront costs with long-term savings.