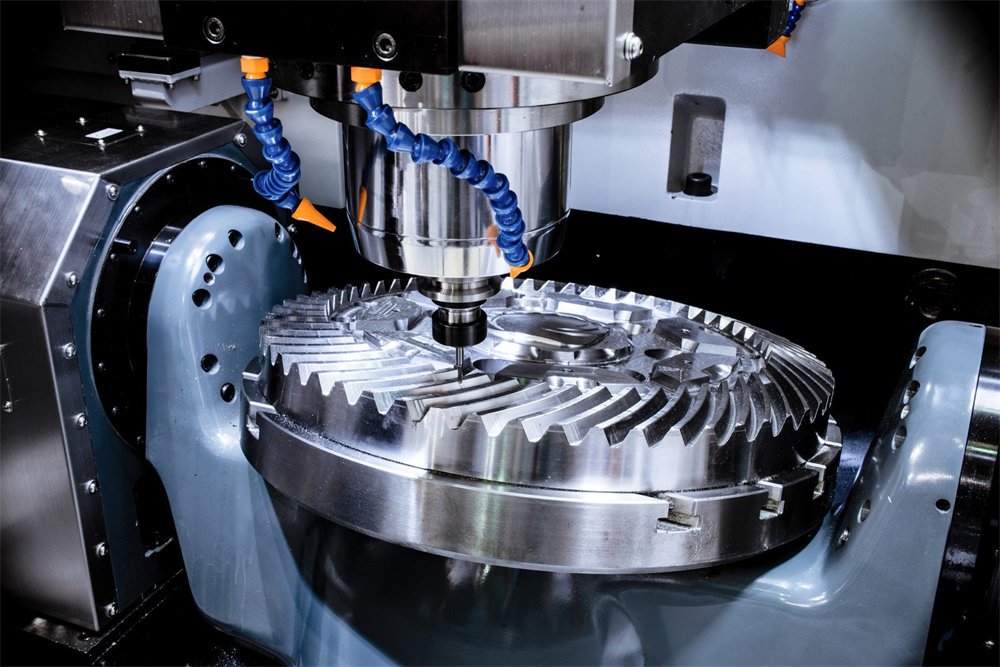

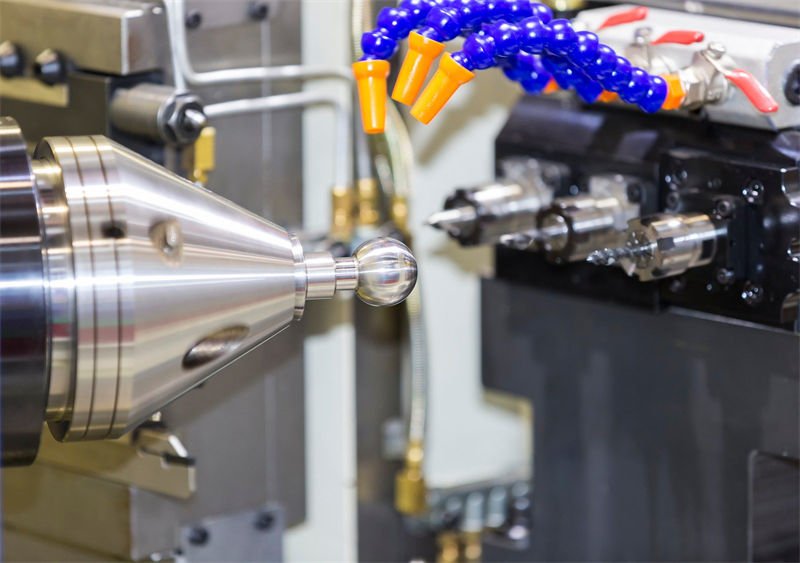

What Types of Parts Can a CNC Lathe Efficiently Process?

CNC lathes are essential in modern manufacturing for processing a wide range of cylindrical and axially symmetrical parts. They excel at crafting shafts, spindles, flanges, gears, bushings, screws, and nuts with remarkable precision and surface quality. The automation capabilities of CNC lathes enhance efficiency by reducing errors and material waste while maintaining consistent quality across production runs. Their adaptability allows for machining complex geometries from diverse materials like carbon steel and stainless steel. With advanced programming and real-time monitoring systems, CNC lathes ensure tight tolerances and exceptional surface finishes crucial for high-performance applications in industries such as automotive and aerospace.

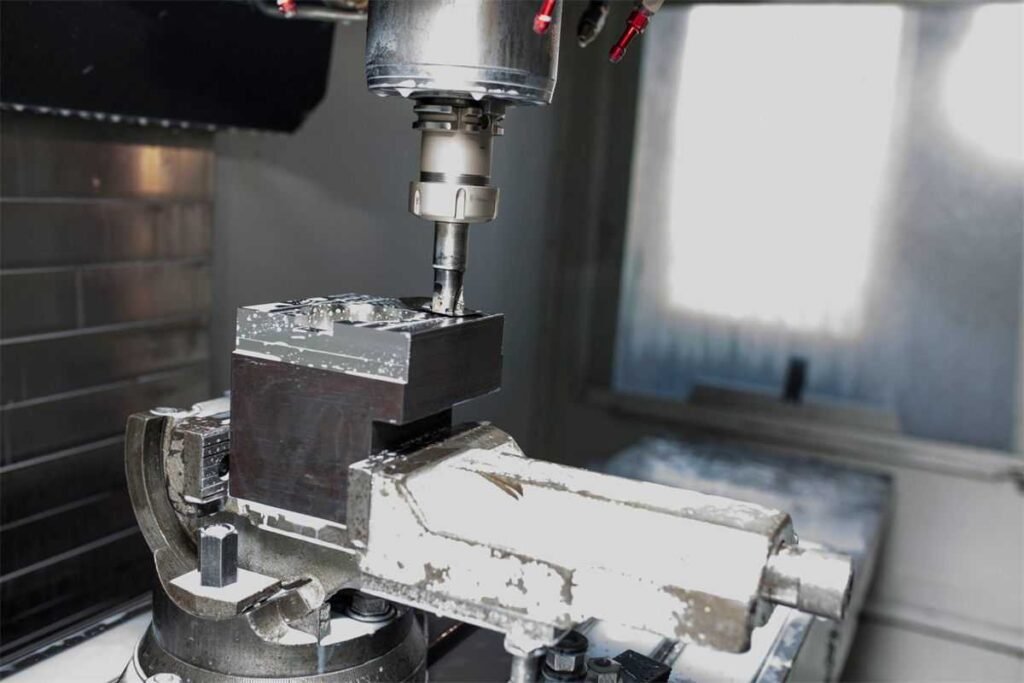

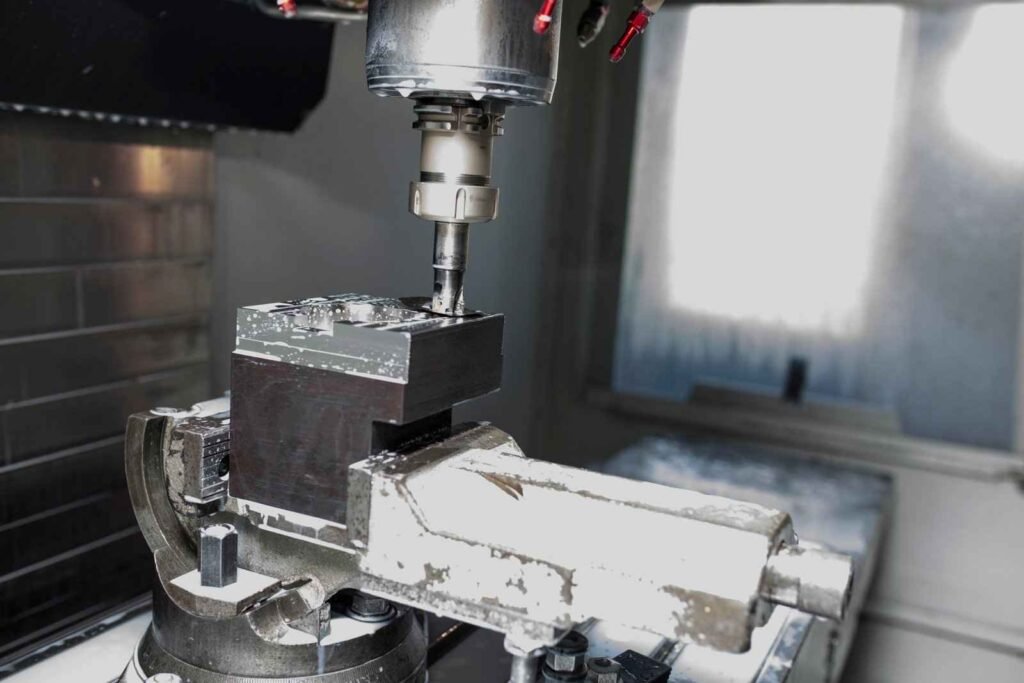

What Essential Factors Should You Consider Before Buying a CNC Mill?

Purchasing a CNC mill can feel overwhelming with so many options available. However, understanding the critical factors—such as machining requirements, performance parameters, control system capabilities, costs, and after-sales support—can significantly ease your decision-making process. This guide breaks down each of these elements to help you make a confident choice tailored to your needs.

How Difficult Is It to Operate a CNC Mill or Lathe?

Embarking on a journey into CNC machining raises an important question: How difficult is it to operate a CNC mill or lathe? This article delves into the skills required, programming complexity, precision challenges, and troubleshooting expertise needed to excel in this high-tech craft. Whether you’re a beginner or looking to enhance your skills, understanding these aspects is crucial.

Why Is the Messer Fiber Laser Cutter So Expensive?

Messer fiber laser cutters are known for their high initial costs, but they offer significant long-term savings through reduced maintenance and energy efficiency. Utilizing advanced technologies like Beam Shaping, Auto-Focus Systems, and Real-Time Monitoring, these machines provide unmatched precision and speed in cutting various materials. While the upfront investment may be higher than traditional CO2 lasers, the operational benefits—including lower energy consumption and minimal upkeep—make them a smart choice for industries requiring reliable performance. Ultimately, investing in Messer fiber lasers is akin to purchasing quality equipment that pays off over time with improved productivity and reduced waste.

How Can a Milling Machine Cut Rectangular Shapes?

Unlock the potential of your milling machine by mastering the art of cutting perfect rectangular shapes. In this article, we’ll explore face milling and peripheral milling techniques, the role of CNC programming, and tips for achieving sharp internal corners. Whether you’re a seasoned machinist or just starting out, these insights will help elevate your projects to professional standards.