Why Is Han’s Laser So Expensive?

Have you ever wondered why Han’s Laser products come with such hefty price tags? It’s not just about the brand name; there are compelling reasons behind the costs. From innovative technology to unparalleled customer support, this article dives deep into what makes Han’s Laser a premium choice in the industry.

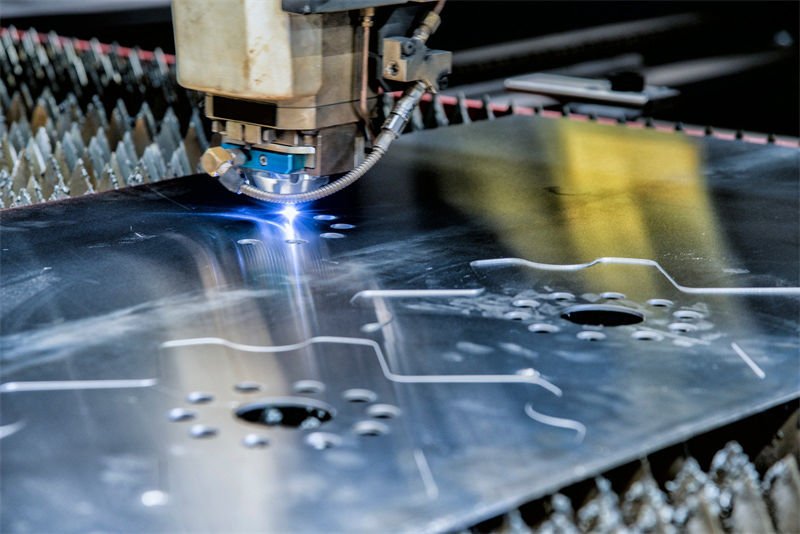

How Does a Fiber Laser Cutting Machine Work?

Fiber laser cutting machines are changing the game in precision and efficiency when it comes to cutting metals and other materials. By understanding how they operate, you can unlock their full potential for your projects. Let’s dive into the key components, differences from CO2 lasers, common issues, and optimization strategies.

How Safe is it to Laser Cut Galvanized Steel?

Laser cutting galvanized steel is a common industrial task, but safety concerns about toxic fumes often arise. Understanding the risks and implementing safety measures is crucial for protecting workers. This article explores the dangers of zinc oxide fumes and offers practical solutions to ensure safe laser cutting practices.

How Effectively Can Aluminium Be Laser Cut?

Aluminium is a popular choice for many manufacturing applications, but its high reflectivity can complicate laser cutting processes. This article explores the challenges of cutting aluminium with lasers and provides insights on optimal settings, equipment choices, and common mistakes to avoid, ensuring high-quality results.

What Are the Applications of Fiber Laser Cutting Machines?

Fiber laser cutting machines are reshaping the landscape of various industries by providing unparalleled precision and efficiency. From manufacturing and automotive to advertising, understanding their diverse applications can lead to significant operational benefits and advancements. This article explores how these machines can be integrated into your operations for enhanced performance.