What Are Laser Engraver and Cutter Machines Used For?

Curious about how laser engraver and cutter machines are transforming industries? You’re not alone. These powerful tools are redefining creativity and precision in both personal and professional projects. From manufacturing to art, discover how these versatile machines can elevate your work.

How Effectively Can a CO2 Laser Engrave Metal?

CO2 lasers are widely recognized for their versatility in engraving materials like wood and plastic. But how do they stack up when it comes to metal? Understanding their limitations and techniques can help you make informed decisions about your engraving projects. This article explores the effectiveness of CO2 lasers on metal, comparing them with fiber lasers, and provides insights on improving engraving quality.

Which Protective Glasses Are Best for Laser Engraving?

Choosing the right protective glasses for laser engraving is crucial for your safety. This guide covers everything you need to know about Optical Density, laser specifications, and safety standards, ensuring your eyes are well protected while working with lasers.

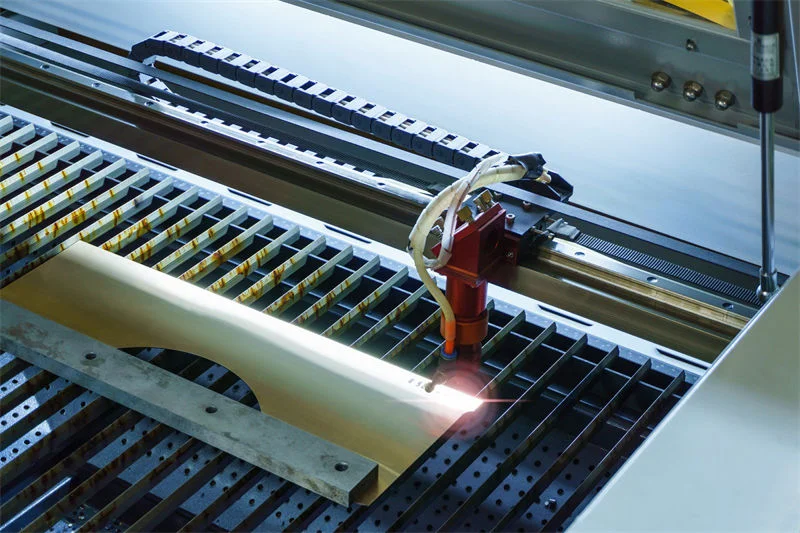

What Are Fiber Laser Marking Machines and How Do They Work?

Fiber laser marking machines are at the forefront of modern industrial marking technology. These machines utilize a high-intensity laser beam to engrave or mark surfaces by altering their properties. Known for their efficiency and versatility, they are essential in various industries such as electronics and jewelry. This article dives deep into how these machines operate, their key applications, and what factors to consider when choosing the right one for your needs.

What Are the Benefits of Using a CO2 Laser Engraver?

In the world of engraving, CO2 laser engravers stand out as versatile tools that cater to both hobbyists and professionals alike. These machines offer exceptional precision and can work with a variety of materials including wood, acrylic, and glass. They not only enhance creative potential but also significantly improve efficiency in production. Whether you are a small business owner or a passionate hobbyist, understanding the benefits of CO2 laser engravers can help you unlock new possibilities for your projects.

What Type of Gas is Best for a Laser Cutting Machine?

When it comes to laser cutting, the choice of gas can significantly influence both the quality of the cut and the efficiency of the process. Each gas—oxygen, nitrogen, and air—has its own unique advantages and potential drawbacks depending on the material being cut. Understanding these differences is essential for optimizing results and reducing costs. In this article, I’ll share my insights on how to choose the right gas for your laser cutting needs based on personal experiences and industry practices.

What Are the Advantages and Disadvantages of Fiber Laser Cutting?

In today’s fast-paced manufacturing world, understanding the advantages and disadvantages of fiber laser cutting can be a game-changer. This technology not only enhances precision and efficiency but also poses certain challenges that businesses must navigate. Join me as I explore this transformative cutting method and its implications for various industries.