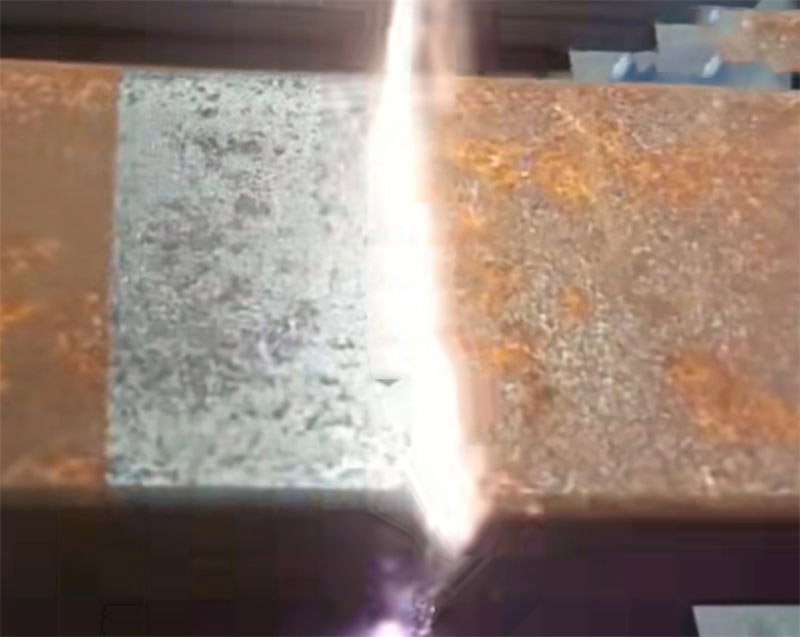

Picture this: a laser cleaning marvel that transforms rusty metal back to its former glory with ease and precision.

The 100W laser rust removal machine shines in metal cleaning for its pinpoint accuracy and eco-friendly, contact-free method that swiftly banishes rust without harming the base material. It’s a game-changer for those seeking speed and safety in one efficient package.

Reflecting on my journey into the world of laser technology, I remember the first time I witnessed a 100W laser rust removal machine in action. It was like watching a magician erase years of neglect from a forgotten piece of metal, transforming it back into something remarkable.

As someone who’s been around various metal cleaning methods, the laser’s precision and efficiency caught my attention. Traditional methods often felt like using a sledgehammer to crack a nut—effective but not always the best choice for preserving the quality of the metal underneath. This machine, however, was different. It was non-contact and eco-friendly, aligning perfectly with a future-focused approach to metalwork.

When you’re deciding on a laser rust removal machine, it’s not just about clearing rust; it’s about doing so with finesse and respect for the material. It’s essential to weigh these factors and understand how this technology stacks up against older techniques to make an informed choice.

100W laser machines are eco-friendly for rust removal.True

100W laser machines use a non-contact, chemical-free process, reducing environmental impact.

Traditional methods are faster than 100W laser machines.False

Laser machines are faster due to their precision and efficiency in rust removal.

How Does Laser Cleaning Compare to Traditional Rust Removal Methods?

Imagine a world where rust just disappears without a scratch on your precious metal. That’s the magic of laser cleaning!

Laser cleaning is a superior alternative to traditional rust removal methods, offering unmatched precision and efficiency. It preserves the underlying material, providing a non-contact, eco-friendly solution perfect for delicate surfaces.

Efficiency and Precision

When I first encountered laser cleaning, it felt like discovering a cheat code in a video game. It’s incredibly precise, using a focused laser beam to zap away rust without harming the material underneath. This non-contact method is like having a superpower that sandblasting or grinding just can’t match—those methods can wear down surfaces over time, like sandpaper on a favorite pair of jeans.

| Method | Precision | Material Impact | Contact Type |

|---|---|---|---|

| Laser Cleaning | High | Minimal | Non-contact |

| Sandblasting | Moderate | High | Contact |

| Chemical Stripping | Low | Variable | Contact |

Environmental Considerations

I remember the first time I realized how much traditional methods can harm our planet. The chemicals used often end up polluting the environment. In contrast, laser cleaning doesn’t produce waste—it’s like the eco-warrior1 of rust removal. This green approach is essential, especially for industries aiming to reduce their carbon footprint.

Cost and Accessibility

I won’t lie—laser cleaning equipment can be pricey upfront. But think of it like investing in a high-quality toolset that saves you money in the long run through reduced maintenance and boosted efficiency. For smaller businesses, the initial cost might seem daunting, but the payoff can be worth it if planned carefully.

Versatility Across Applications

One of the things I love most about laser cleaning is its versatility. Whether you’re preserving historic artifacts or maintaining industrial equipment, this method adapts beautifully. You can tweak laser settings to suit different materials and levels of rust, making it as flexible as a gymnast.

For folks like Ferudun and Alexander, who are deeply involved in the laser industry2, understanding these nuances can help in making smarter investment choices. By weighing each method’s unique features, they can tailor their decisions to balance cost-effectiveness with operational needs. And that, my friends, is the kind of savvy business strategy we all strive for.

Laser cleaning is more precise than sandblasting.True

Laser cleaning uses a focused beam, ensuring high precision.

Chemical stripping is a non-contact rust removal method.False

Chemical stripping involves direct contact with the material.

What makes a 100W laser rust removal machine stand out?

Imagine effortlessly removing rust with the precision of a laser beam. That’s exactly what a 100W laser rust removal machine can do!

A 100W laser rust removal machine efficiently removes rust with high precision. Key features include adjustable power settings, portability, minimal maintenance, and eco-friendly operation, making it suitable for diverse industrial uses.

Efficiency and Precision

There was a time when I wrestled with bulky sanders and harsh chemicals to get rid of rust. It felt like trying to scrub out a permanent marker stain with a tissue! But then I discovered the 100W laser rust removal machine—a game-changer. This machine offers a non-contact solution3 that preserves the metal’s integrity, unlike my past abrasive methods. It’s like using a magic wand that sweeps away rust without damaging what’s underneath.

Adjustable Power Settings

I remember working on an old project car with varying rust intensities across different panels. With this machine’s adjustable power settings, I felt like a conductor orchestrating the perfect performance. I could fine-tune the laser to match the rust level—whether I was delicately cleaning a fragile surface or tackling a more stubborn spot.

Portability and Design

One of my favorite features is its portability. It’s as if someone finally understood my need to move equipment without feeling like I’m hauling a boulder. These machines are compact and lightweight, with ergonomic designs that let me glide them from one worksite to another effortlessly.

Minimal Maintenance and Cost Efficiency

I used to dread maintenance days—spending hours cleaning and replacing parts felt like a chore. But with this laser rust remover, maintenance is as simple as regular lens cleaning and the occasional software update. This simplicity translates into long-term cost savings and less downtime4, allowing me to focus on what truly matters—my work.

Eco-Friendly Operation

Operating this machine feels like giving back to the planet. No more harmful chemicals or noisy operations. It’s a quiet, eco-friendly option that ensures safer working conditions. It’s comforting to know that I’m not just making things cleaner but doing it in a way that respects the environment.

| Feature | Benefit |

|---|---|

| Efficiency | Quick and precise rust removal |

| Adjustable Settings | Customizable for various applications |

| Portability | Easy movement across work sites |

| Minimal Maintenance | Lower operational costs |

| Eco-Friendly | Safe and sustainable industrial solution |

By diving into these features, I’ve been able to make informed decisions on integrating these machines into my workflow, optimizing performance and cost-effectiveness5. Whether you’re considering one for your business or personal projects, understanding these key elements can be transformative.

100W laser rust removers require frequent part replacements.False

They primarily need lens cleaning and software updates, not part replacements.

Laser rust removal is an eco-friendly method.True

It eliminates harmful chemicals and reduces waste, enhancing safety.

Why is Laser Rust Removal Considered Eco-Friendly?

Ever wondered why laser rust removal is making waves in the eco-friendly world? It’s not just sci-fi tech; it’s a cleaner, greener alternative to traditional methods. Let me walk you through why this innovation is a game-changer.

Laser rust removal is eco-friendly because it skips harsh chemicals, cuts down on waste, and saves energy. Instead of abrasive methods, it uses precise laser beams that clean without leaving a mess, making it a sustainable choice for industries.

Understanding Laser Rust Removal

I remember the first time I witnessed laser rust removal in action. It was like watching a magic trick—only better because it was real and had practical benefits. The process uses high-energy laser beams to delicately vaporize rust from metal surfaces, preserving the material underneath without a scratch. Unlike traditional methods that rely on chemical baths or sandpaper-like abrasives, lasers are all about finesse. They offer pinpoint accuracy, which is perfect for those delicate jobs where you don’t want to damage the item you’re cleaning.

Comparison with Traditional Methods

| Method | Chemical Use | Waste Production | Surface Damage Potential |

|---|---|---|---|

| Laser Removal | None | Minimal | Low |

| Chemical Strips | High | High | Moderate |

| Sandblasting | None | Moderate | High |

When I think about the old-school methods like chemical stripping or sandblasting, I can almost smell the pungent fumes and feel the grit everywhere. In contrast, laser technology sweeps away these concerns. It’s like comparing a scalpel to a sledgehammer; the laser gently vaporizes rust, leaving behind only a clean, pristine surface.

Energy Efficiency and Sustainability

One of the first things that drew me to laser rust removal was its energy efficiency. Operating a laser system requires significantly less power than running hefty mechanical equipment or maintaining extensive chemical facilities. It’s like switching from a gas-guzzler to a sleek electric car—the savings on energy are immense and contribute to its green reputation.

Environmental Impact and Safety

Not only does laser rust removal reduce environmental impact by cutting down on pollutants, but it also creates a safer work environment. I once visited a factory that had made the switch, and the difference was clear—gone were the masks and heavy-duty protective gear. Instead, workers operated in a clean, comfortable space with minimal exposure to harmful substances.

Applications Across Industries

The versatility of laser rust removal means it can be used across various industries—from restoring vintage cars to maintaining aircrafts. I’ve seen its versatility6 firsthand, ensuring eco-friendly practices are woven into the fabric of different industrial settings. It’s not just about removing rust; it’s about doing so responsibly and sustainably.

Laser rust removal uses no chemicals.True

Laser rust removal avoids harsh chemicals, making it eco-friendly.

Sandblasting produces less waste than laser removal.False

Sandblasting generates moderate waste, while laser removal minimizes it.

What Should You Consider Before Buying a 100W Laser Rust Removal Machine?

Imagine this: You’ve finally decided to invest in a 100W laser rust removal machine, but the sheer number of options leaves you overwhelmed. How do you choose the right one without regretting your purchase?

Before buying a 100W laser rust removal machine, consider factors like power efficiency, application versatility, maintenance needs, cost-effectiveness, and supplier reliability to ensure a smart investment.

Understanding Power Efficiency

The power efficiency of a 100W laser rust removal machine is like the engine of a car—you want it powerful yet economical. I’ve found that comparing energy consumption rates across different models can save you headaches later on. It’s about finding that sweet spot where you get the best rust removal without burning through electricity. Consider the energy efficiency ratings7 from various manufacturers to make an informed decision.

Application Versatility

Every rust removal task comes with its quirks, much like trying to use a Swiss Army knife for every job. Some machines handle steel like a breeze, while others might falter on aluminum. It’s essential to know whether your machine can tackle multiple materials. Research versatile laser machines8 that offer flexibility for multiple applications to ensure you’re covered for any job.

Maintenance and Durability

Just like how you wouldn’t drive your car for miles without a check-up, laser machines need regular care. Trust me, I’ve learned that the hard way! Investigate the ease of servicing and availability of replacement parts upfront. Machines with a solid build will mean fewer breakdowns and unexpected costs. Check maintenance requirements9 for different models to avoid unexpected expenses.

Cost-Effectiveness Analysis

I always say, "Don’t just look at the sticker price." The initial cost is just the beginning; think about long-term savings too. For instance, how much time will you save in labor? A side-by-side comparison like this can really illuminate which model suits your budget:

| Model | Initial Cost | Operating Cost (Yearly) | Potential Savings |

|---|---|---|---|

| Model A | $10,000 | $500 | $1,200 |

| Model B | $9,500 | $600 | $1,300 |

Dive into these numbers and see which offers the best bang for your buck in the long run.

Supplier Reliability

I’ve learned that picking a supplier is as crucial as choosing the machine itself. You want someone who’s got your back, not just before the sale but long after. Look into the supplier’s history, customer reviews, and warranty policies. Building relationships with trusted suppliers10 can be invaluable in ensuring smooth operations.

By weighing these factors carefully, you’ll be in a strong position to choose a machine that not only meets your needs but also helps your business thrive without unexpected bumps along the road.

100W laser machines are always energy efficient.False

Efficiency varies by model; compare energy ratings to ensure efficiency.

Supplier reliability affects machine performance.True

Reliable suppliers ensure quality and timely support, impacting performance.

Conclusion

The 100W laser rust removal machine excels in precision, eco-friendliness, and efficiency, making it a superior choice for metal cleaning compared to traditional methods.

-

Learn why laser cleaning is considered an eco-friendly rust removal option with minimal environmental impact. ↩

-

Explore diverse industrial applications where laser cleaning proves beneficial due to its versatility and precision. ↩

-

Learn about how laser technology ensures minimal material loss while cleaning surfaces. ↩

-

Find out about maintenance needs to keep your machine in top condition. ↩

-

Explore how these machines can save costs over time compared to traditional methods. ↩

-

Discover how different industries apply laser rust removal and its benefits in various settings. ↩

-

Check energy efficiency ratings to ensure the machine operates cost-effectively over time. ↩

-

Explore versatile machines that handle multiple materials for diverse applications. ↩

-

Understand maintenance needs to prevent downtime and unexpected costs. ↩

-

Find reliable suppliers to ensure quality and support after purchase. ↩